Servicing the Transfer Cap Assemblies

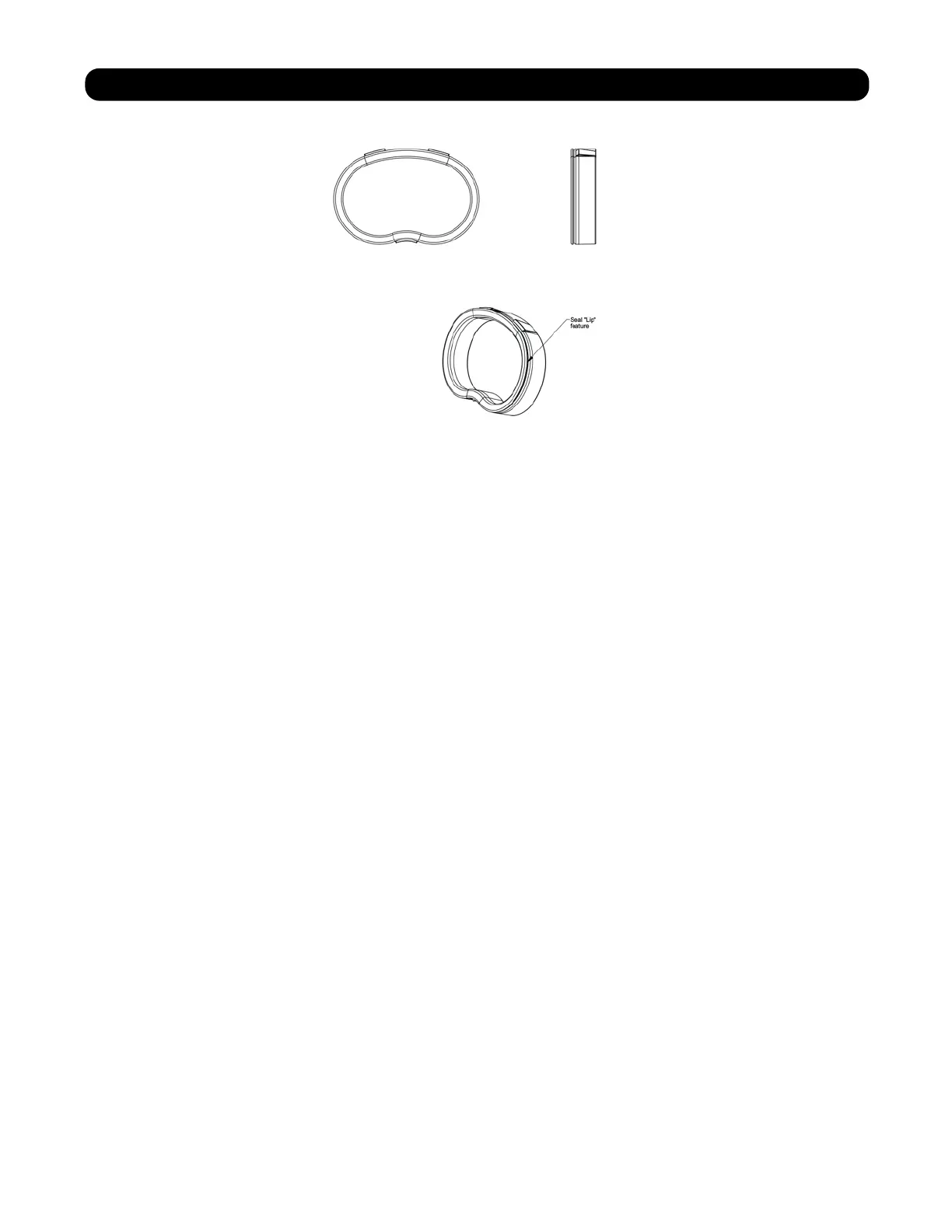

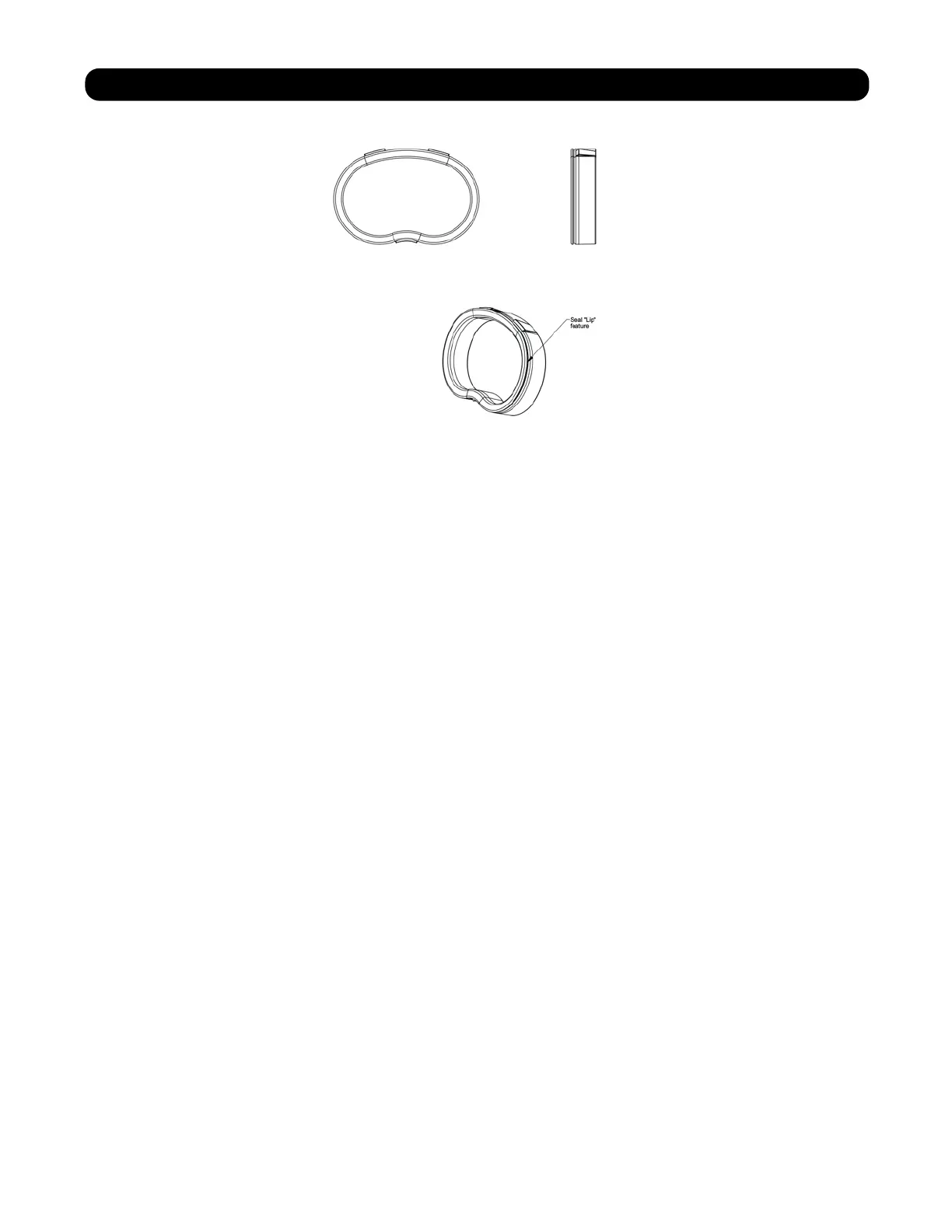

To remove seals gently pull out on the outer lip of the seal to lift the seal out from its

cavity being careful not to damage the face surface of the seal. To reassemble re-seat

the seals into the seal cavity of the control valve body being sure that the lip of the seal

is facing outward. With seals in place put a thin film of silicone grease on the tops of the

seals and the flat surface of the discs. Prior to reinstalling the discs the drive shaft

should be removed and the O-rings cleaned, inspected and lubricated with silicone

grease. The shaft can then be installed into the disc prior to installation. With the outlet

disc assembled to the shaft the orientation of the shaft to the inlet disc can be assured

by installing the set with the through hole on the outlet disc at the six o’clock position.

The easiest thing would be to remove both disc drives and assemble the outlet side first

then each disc could be fitted on the shaft individually. At this point the transfer valve cap

assemblies can be reinstalled. Note: That both transfer caps only mount in one

orientation. Prior to installation of cap assembly be sure to check that the stainless steel

spring and the plastic spring support is in place attached to the middle of the cap

assembly. Next you can wipe the outside edge of the O-ring on the cap and the inside

mating area of the valve with a clean cloth and reapply a thin layer of silicone grease.

BE SURE NOT TO USE ANYTHING HYDRO CARBON BASED SUCH AS VASELINE OR PETROLEUM

JELLY TO LUBRICATE PLASTIC COMPONENTS OR O-RINGS AS THEY WILL BE DAMAGED BY

THE HYDROCARBONS AND POTENTIATLLY CAUSE FAILURES THAT CAN RESULT WITH LEAKS.

Loading...

Loading...