Dok.-Nr.: D10029.EN Rev.: 11 Page 26 of 30

Manual: Water separator / Fuel pre-filter SWK-2000

Willibrord Lösing

Filterproduktion GmbH

W. Lösing Filterproduktion GmbH • Am Walzwerk 2 • 45527 Hattingen

Maintenance 9

For all maintenance works pay attention on providing suitable container under the SWK-2000 to

catch spilled fuel and for proper disposal (s. chap. 12).

Basically, the housing of the Separ filter is maintenance free. The maintenance is restricted to

removal of accumulated water in the bowl and to regular replacement of the filter element.

When screws of the filter are loosen and tightened again, please observe the tightening torques

(s. chap. 9.1).

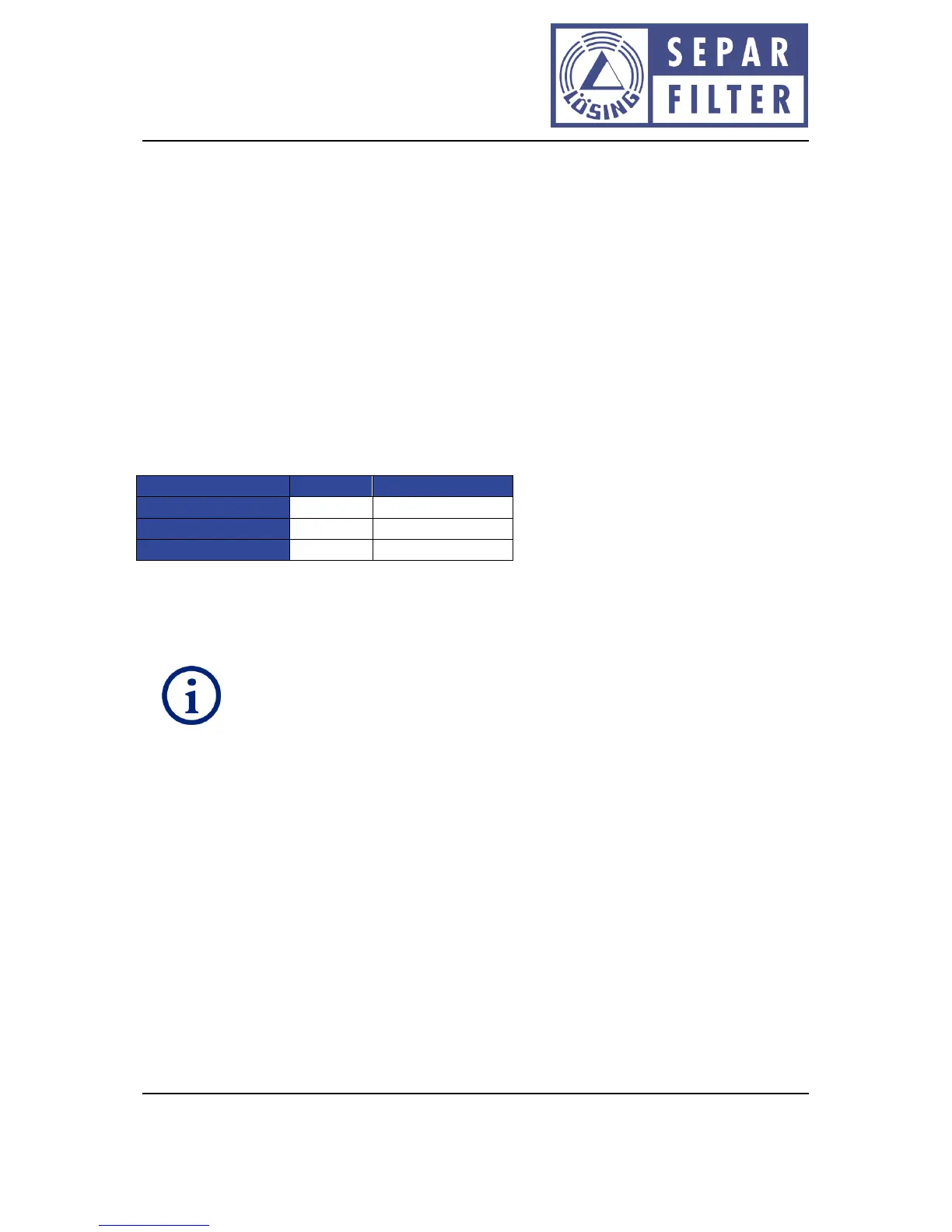

9.1 Tightening torques

The tightening torques listed to be strictly observed. Lid and bowl retainer ring screws have to be

tightened in multipile turns and crosswise. Shown torques will result in no leakages of the filter and

avoid damages to the filter.

9.2 Drainage of water

If you find accumulated water at the bottom of the bowl, or the water sensor (optional) has

triggered an alarmwater has to be drained out of the bowl.

You should, if water has collected in the bowl, not wait to long with the drainage, as

within a few days visible biomass might be foundat the interface between water and

diesel fuel. This defines itself as pollution to the bowl wall and can, if it dissolves,

reduce the service life of the filter element.

The following describes how the drainage must be performed. Make sure that during the operation

no fuel can escape into the environment. Collect the fuel and dispose it properly (s. chap. 12).

1. Shut down the engine.

2. Close, if available, the shut off valve before the filter. In case of switchable filters switch lever

to the other filter.

3. Open the bleed screw above the filter lod.

4. Open the drain valve. Water and dirt are flushed out of the bowl. Leave the drain valve open

as long until cleaned fuel leakes. Collect drained fluids in a container and dispose as per local

regulations.

5. Close the drain valve and the bleed screw (observe the tightening torque, s. chap. 9.1).

Loading...

Loading...