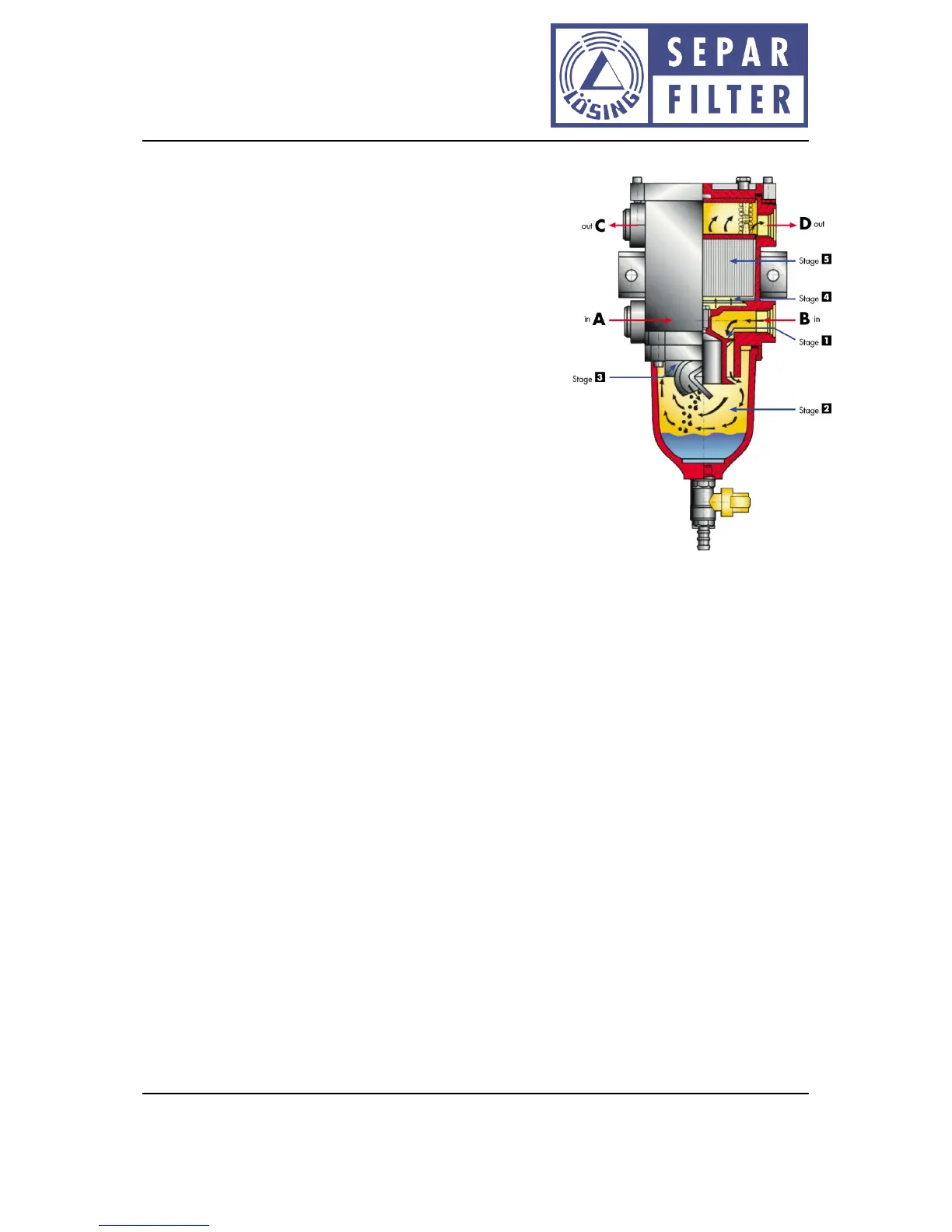

Stage 3

In the further flow the fuel passes the outer vane system. By

the different length of the vanes and the twofold change in the

fuel flow direction, smaller water droplets and fine dirt

particles settle on the vanes, where they agglomerate and than

decline, caused by gravity, down to the bottom of the bowl.

Already at this point the major portion of any contaminates in

the fuel have been separated.

Stage 4

Below the filter element, on the so-called dome, the flow

cross-section is considerably increased, whereby a slow-down

of the fuel occurs. This also allows smallest water droplets and

dirt particles to settle. Through the previous pre-separation,

the majority of the contamination (water and dirt) settles in

the bowl and prolongs significantly the lifetime of the filter

element.

Stage 5

The remaining suspended contamination in the fuel, finest water droplets and smallest particulates

are filtered by a replaceable filter element which is produced from a special cellulose paper or

stainless steel mesh elements.

The clean fuel leaves the filter through one of the outlet ports (the port not required should be

sealed off with the plug attached) and continues through thefuel system.

2.3 Fields of application of the filter

Vehicle industry – trucks, busses, crane trucks, municipal vehicles, etc.

Construction machinery, agricultural machinery, forklifts, compressors, etc.

Ship propulsion motors, auxialliary units

Stationary engines and generators, welding and pumping units

Mining machinery, rail vehicles

Loading...

Loading...