3.9

3.4 Continuous mode

In continuous mode a data frame is transmitted by the serial output port at a user defined

interval. The format of the data frame is given in Table 3.6 and 3.7. However, it is a list of

process variables (or 'fields') preceded by a start character, separated by semi colons and

terminated by carriage return and line feed, i.e.:

A;B;C;D;E;F;G;H;I;J;K;L;M;............;N;<CR><LF>

The frame frequency and generic communications parameters are configured in the analyser

software (refer to Quickstart manual), note the 'frame frequency' sets up the frequency of

transmission of the data frame down the serial communications port. For example if the value

is set to 15 seconds then the output data frame will be transmitted once every 15 seconds. The

frequency is set in steps of one seconds from 1 to 9999 seconds. If the value is set to zero then

the transmission of data down the serial port stops and will not restart until a non zero value is

entered.

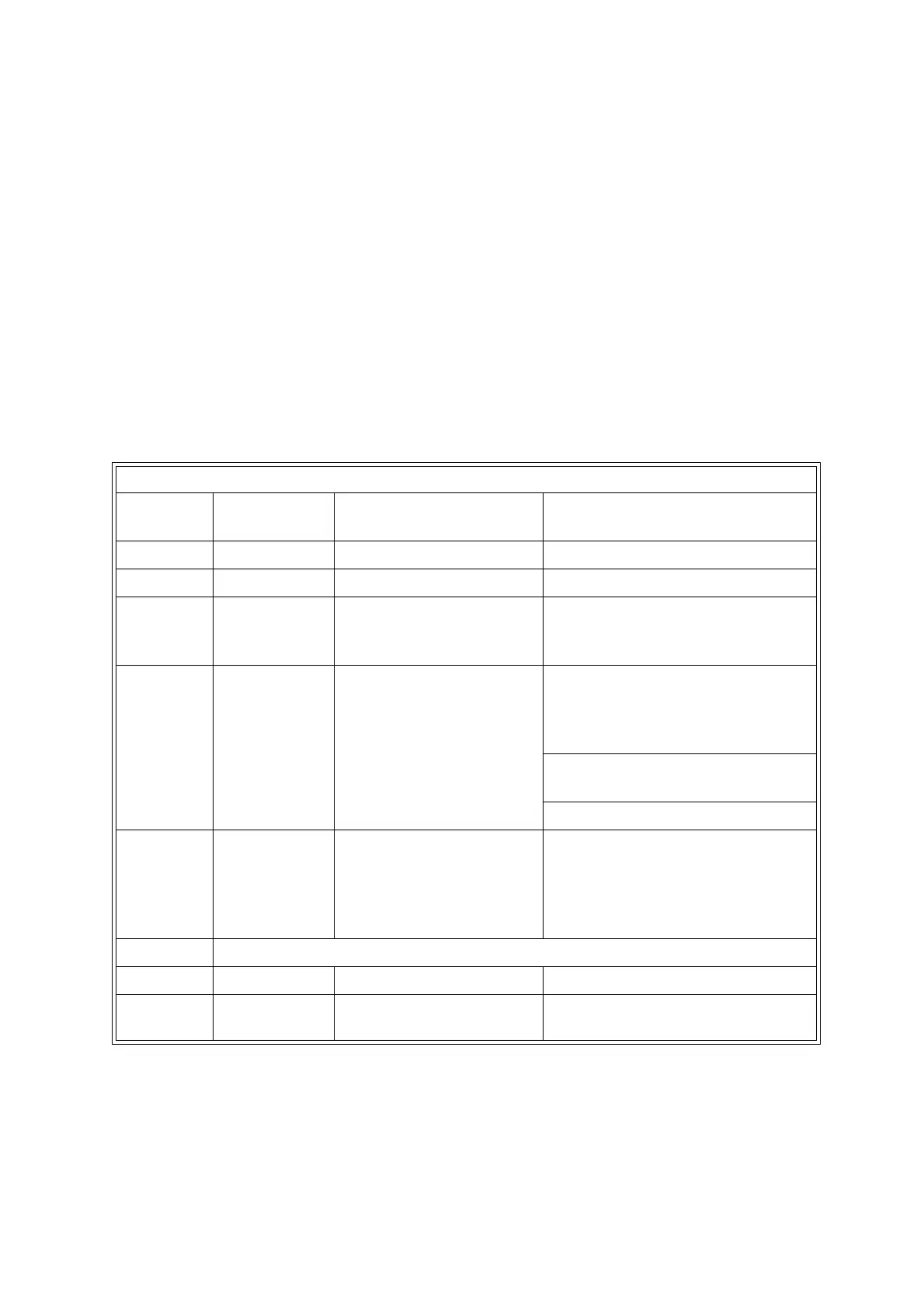

Table 3.6: Serial output data frame, start and end sequences

Field Number of

characters

Function Entry/format

A 8 date DD-MM-YY

B8time HH:MM:SS

C 2 analyser failure and

maintenance fault status

first character F for failure, second

character M for maintenance

(spaces = OK)

D 8 Autocalibration 'flags',

two characters for each

of the four calibration

groups

first character: group 1, S for

sample, C for calibration gas

second character: group 1, 1 for

cal gas 1, 2 for cal gas 2

etc, for groups 2, 3 then 4

E 2 number of process

measurements or

'variables'

03 to 07, the following fields will be

repeated for each transducer and

any derived measurements. The

last two variables will always be

the two external inputs (E1, E2)

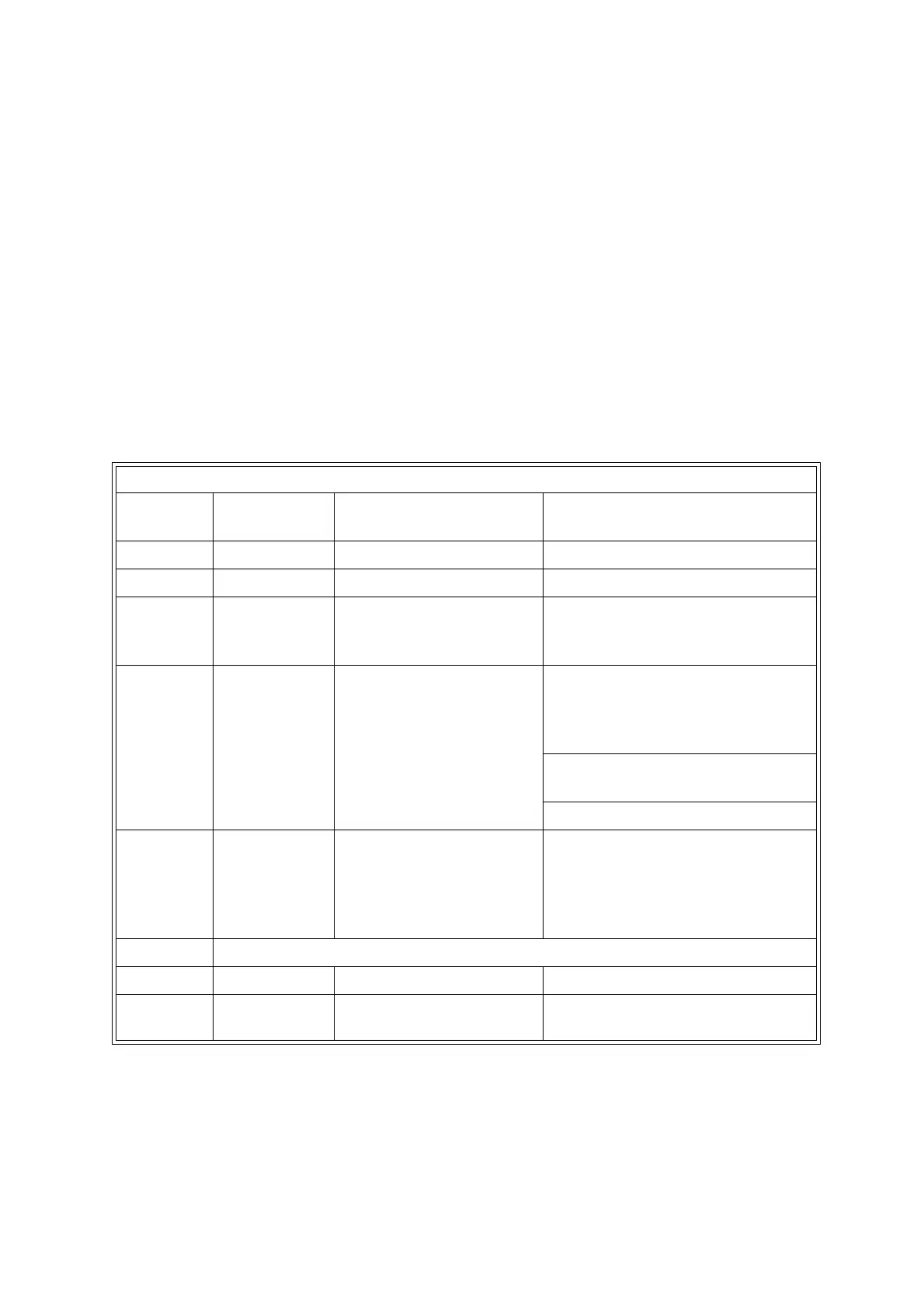

F-M measurement sequences, refer to Table 3.7

N 4 check sum e.g.: 096A

- - end code, <CR> and

<LF>

ASCII code 13 and 10

Loading...

Loading...