Do you have a question about the SFA SANICUBIC 2 PRO and is the answer not in the manual?

Details symbols and their meanings for DANGER, WARNING, Dangerous area, Dangerous voltage, and Property damage.

Provides essential instructions for safe operation, installation, and maintenance of the SANICUBIC® pumping station.

Specifies the authorized applications and conditions for operating the pumping station.

Outlines requirements for qualified professionals performing installation and maintenance.

Covers essential safety precautions before, during, and after maintenance and installation activities.

Warns about potential loss of warranty and damages from not following the manual.

Instructions for checking the pumping station's packaging upon delivery for any damage.

Guidance on safe handling and transport, including weight considerations and precautions.

Precautions to take for storing the pumping station to ensure its integrity.

Steps for returning the pumping station, emphasizing draining and decontamination.

Information on environmentally responsible disposal of the pumping station unit.

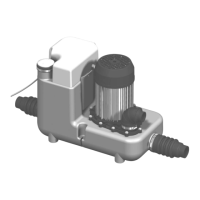

Overview of the SANICUBIC® range, its applications, and compliance with standards.

Lists the standard components included with the SANICUBIC® pumping stations.

Details about the information found on the pumping station's rating plate.

Explains the mechanical design and how the pumping station functions during operation.

Presents key technical specifications for different SANICUBIC® models.

Covers electrical characteristics, detection device specs, and control box dimensions.

Details alarm unit features, dimensions, and options for external alarm connections.

Description of the sump tank's design for pressure-free wastewater collection.

Specifies authorized and unauthorized fluids for pumping and associated risks.

Information on the expected sound pressure level of the pumping station.

Guidelines for selecting the installation location and preparing the site.

Crucial safety instructions and requirements for connecting the pumping station electrically.

Instructions on correctly positioning and securing the pumping station unit.

Details on connecting inlet, discharge, and ventilation pipes with safety notes.

Guidance on using a submersible pump for automatic cellar drainage and preventing flooding.

Steps and conditions required before starting up the pumping station for the first time.

Specifies the operational limits for fluid temperature and room temperature.

Recommendation to limit the number of engine starts per hour to prevent overheating.

Instructions for the initial startup procedure using the control box.

Procedure for safely shutting down and removing the pumping station.

Explains how to operate the control box, including general alarms and mains status.

Details the operation of wired and HF alarm units, including LED indicators and alarms.

Essential safety and preparation guidelines before performing any maintenance.

Outlines required maintenance checks and inspection intervals according to standards.

Recommendation to engage a qualified company for regular maintenance.

Steps for ensuring continued operation when one pump is unavailable for maintenance.

Procedures for checking motor hydraulics, cleaning, and disassembling the motor.

Covers disassembly of chambers, sensor reassembly, general reassembly, and torque specifications.

A checklist for verifying correct installation, inspection, and maintenance procedures.

| Brand | SFA |

|---|---|

| Model | SANICUBIC 2 PRO |

| Category | Water Pump |

| Language | English |