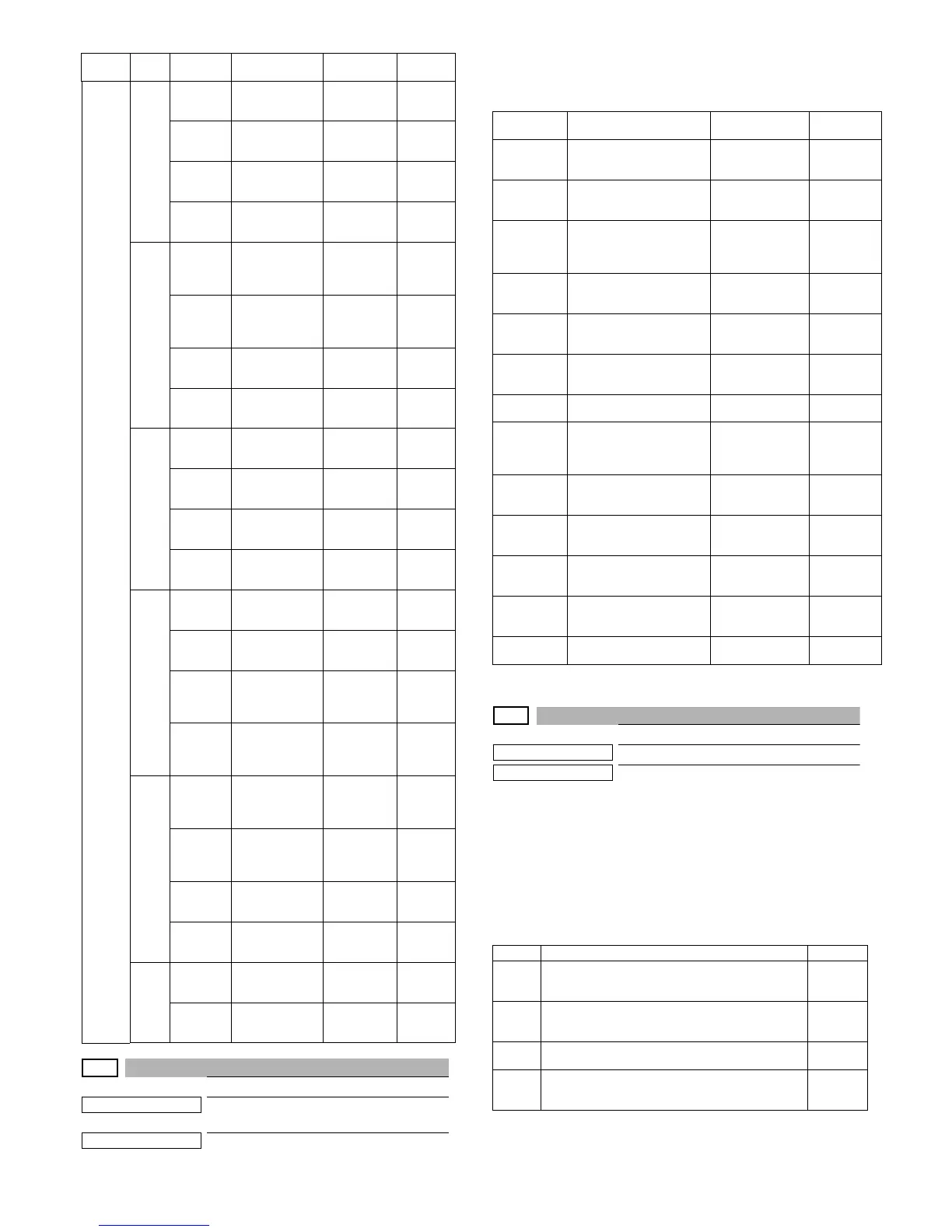

MX-C250 SIMULATION 6 – 38

44-14

Purpose

Operation data display

Function (Purpose)

Used to display the output level of the tem-

perature and humidity sensor.

Section

Process (OPC drum, development)/Fusing/

LSU

Operation/Procedure

The output levels of the fusing temperature sensor, the machine

temperature sensor, and the humidity sensor are displayed.

* above AD values are changed to hexadecimal

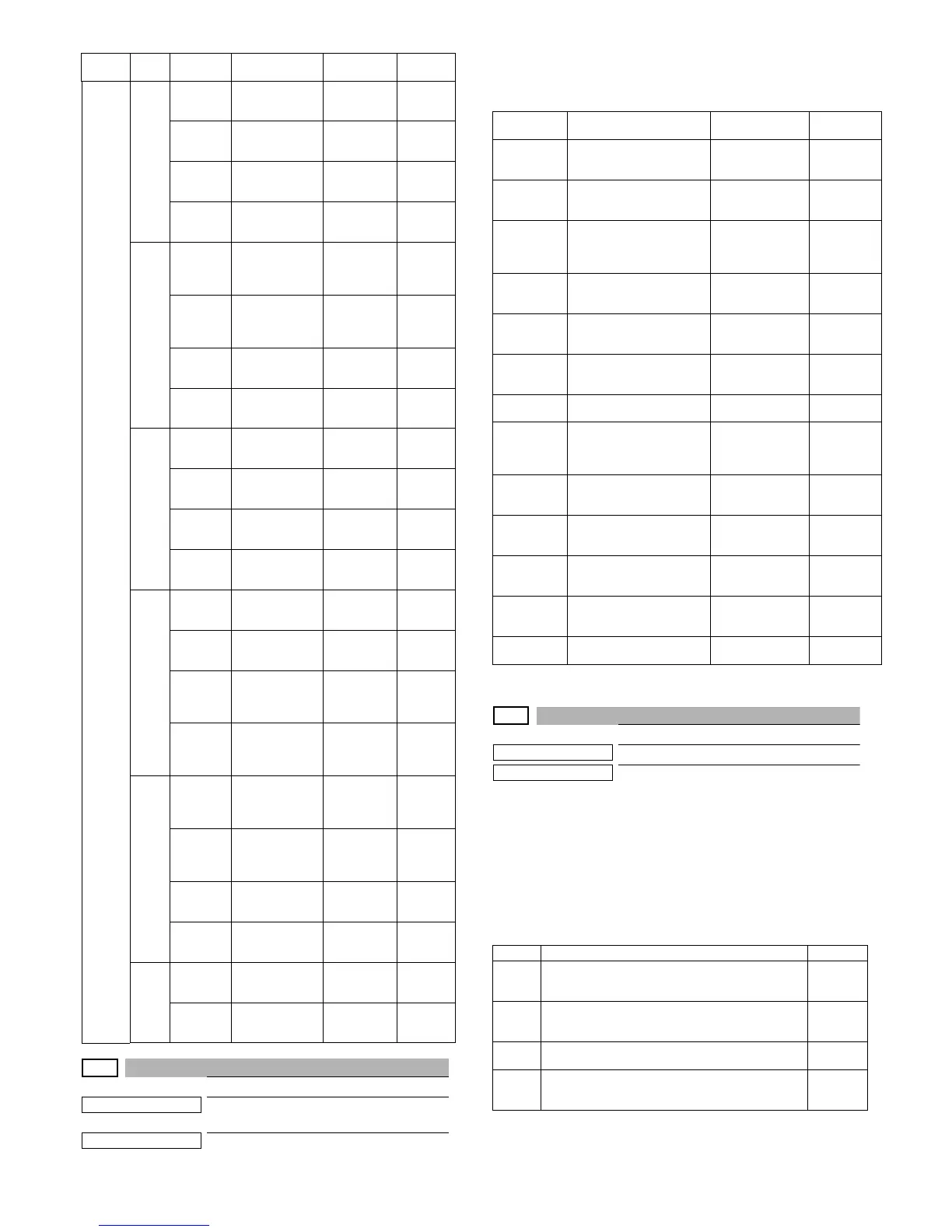

44-15

Purpose

Operation data display

Function (Purpose)

Used to set the OPC drum idle rotation.

Section

Developing system

Operation/Procedure

1) Select an item to be set with Arrow keys.

2) Enter the set value with 10 keys.

3) Press [OK]/[START] key.

The set value in step 2) is saved.

NOTE:

Set the items to the default values unless a change is spe-

cially required.

PATCH

18/

23

Y1

High density

process control

patch data 4_Y1

0 - 255 0

Y2

High density

process control

patch data 4_Y2

0 - 255 0

Y3

High density

process control

patch data 4_Y3

0 - 255 0

Y4

High density

process control

patch data 4_Y4

0 - 255 0

19/

23

Bk_BASE

5

High density

process control

patch data

5_K1_BASE

0 - 255 0

CL_BASE

5

High density

process control

patch data

5_C1_BASE

0 - 255 0

K1

High density

process control

patch data 5_K1

0 - 255 0

K2

High density

process control

patch data 5_K2

0 - 255 0

20/

23

K3

High density

process control

patch data 5_K3

0 - 255 0

K4

High density

process control

patch data 5_K4

0 - 255 0

C1

High density

process control

patch data 5_C1

0 - 255 0

C2

High density

process control

patch data 5_C2

0 - 255 0

21/

23

C3

High density

process control

patch data 5_C3

0 - 255 0

C4

High density

process control

patch data 5_C4

0 - 255 0

M1

High density

process control

patch data

5_M1

0 - 255 0

M2

High density

process control

patch data

5_M2

0 - 255 0

22/

23

M3

High density

process control

patch data

5_M3

0 - 255 0

M4

High density

process control

patch data

5_M4

0 - 255 0

Y1

High density

process control

patch data 5_Y1

0 - 255 0

Y2

High density

process control

patch data 5_Y2

0 - 255 0

23/

23

Y3

High density

process control

patch data 5_Y3

0 - 255 0

Y4

High density

process control

patch data 5_Y4

0 - 255 0

Mode Page Item Content Range

Default

Value

ITEM CONTENT Range

Default

value

TH_UM

(deg)

Fusing main thermistor

detection temperature

(Temperature degrees C)

Temperature 0 -

255degrees C(+/-

1degrees C)

Measured

value

TH_UM_AD

(hex)

Fusing main thermistor dif-

ferential input AD value

(AD value)

AD value 0 - 1023

Measured

value

TH_UM_AD

1(deg)

Fusing main thermistor

compensation sensor tem-

perature (Temperature

degrees C)

Temperature 0.0 -

255.0degrees

C(+/-0.1degrees

C)

Measured

value

TH_UM_AD

1(hex)

Fusing main thermistor

compensation sensor, AD

value V

AD value 0 - 1023

Measured

value

TH_UM_AD

2(hex)

Fusing main thermister

detection sensor AD value

(AD value)

AD value 0 - 1023

Measured

value

TH_US(deg)

Fusing sub thermistor

detection temperature

(Temperature degrees C)

Temperature 0 -

255degrees C(+/-

1degrees C)

Measured

value

TH_US_AD(

hex)

Fusing sub thermistor AD

input value (AD value)

AD value 0 - 1023

Measured

value

TH_M(deg)

Multipurpose tray tempera-

ture sensor AD value (Tem-

perature degrees C)

Temperature -

40.0degrees C -

150.0(+/-

0.1degrees C)

Measured

value

TH_M_AD(h

ex)

Multipurpose tray tempera-

ture sensor AD value (AD

value)

AD value 0 - 1023

Measured

value

HUD_M(%)

Multipurpose tray humidity

sensor AD value (Humidity

%)

Humidity 0.0 -

100.0%(+/-0.1%)

Measured

value

HUD_M_AD

(hex)

Multipurpose tray humidity

sensor AD value (AD

value)

AD value 0 - 1023

Measured

value

TH1_LSU(d

eg)

LSU thermistor 1 AD value

(Temperature degrees C)

Temperature 0.0 -

255.0degrees

C(+/-1degrees C)

Measured

value

TH1_LSU_A

D(hex)

LSU thermistor 1 AD value

(AD value)

AD value 0 - 255

Measured

value

ITEM CONTENT RANGE

TIME

Idle rotation interval (time interval between the previ-

ous OPC drum idle rotation and the next one) setting

(h)

0 - 255

AREA1

Environmental area difference judgment threshold

value setting (difference between the previous OPC

drum idle rotation and the current one)

0 - 5

AREA2

Environmental area conditions (AND condition of the

previous OPC drum idle rotation and the current one)

1 - 15

CYCL

E

Previous rotation time setting (sec) in the process

control when recovered from power ON, preheating /

sleep mode.

0 - 255

Loading...

Loading...