MX-C250 OPERATIONAL DESCRIPTIONS 11 – 5

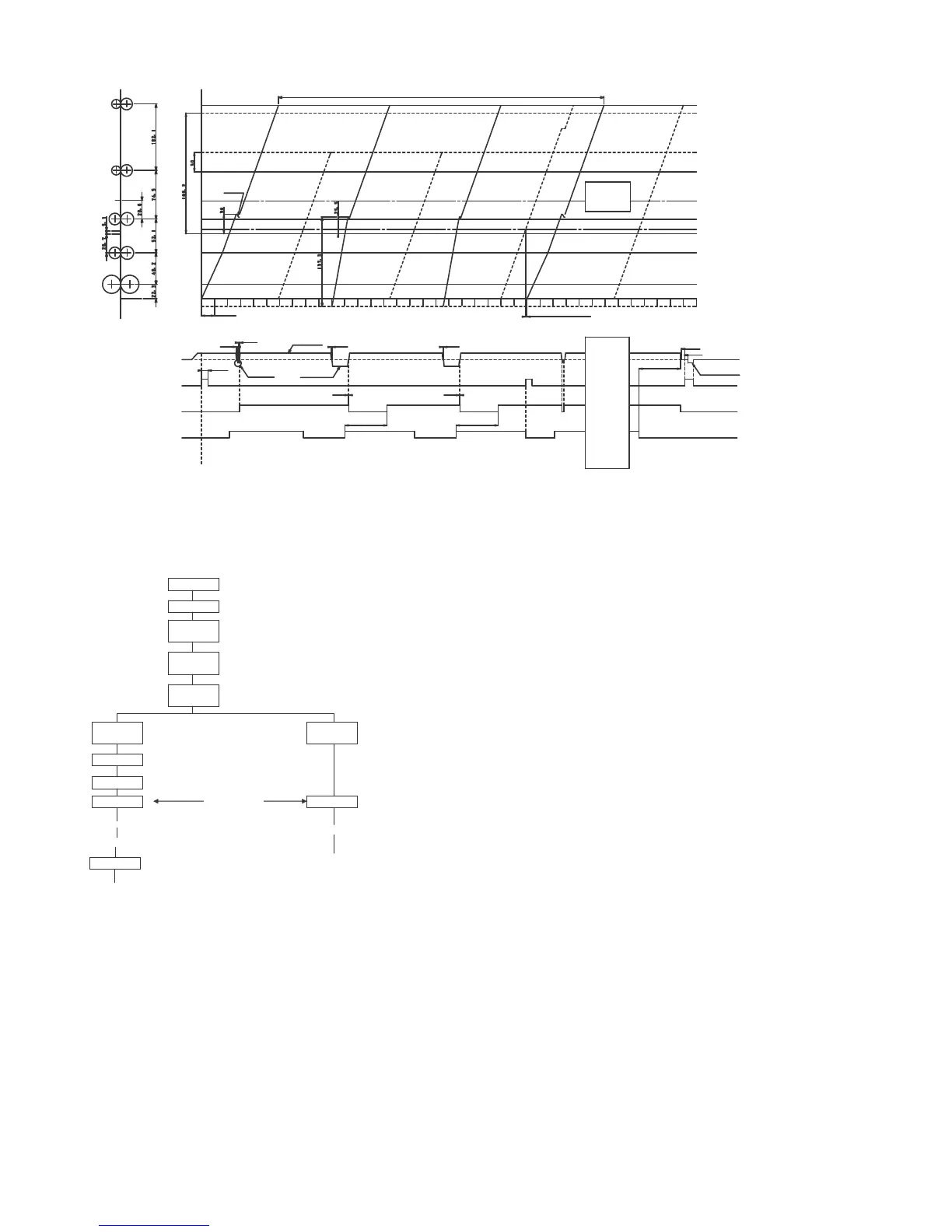

<2-sided scanning timing figure>

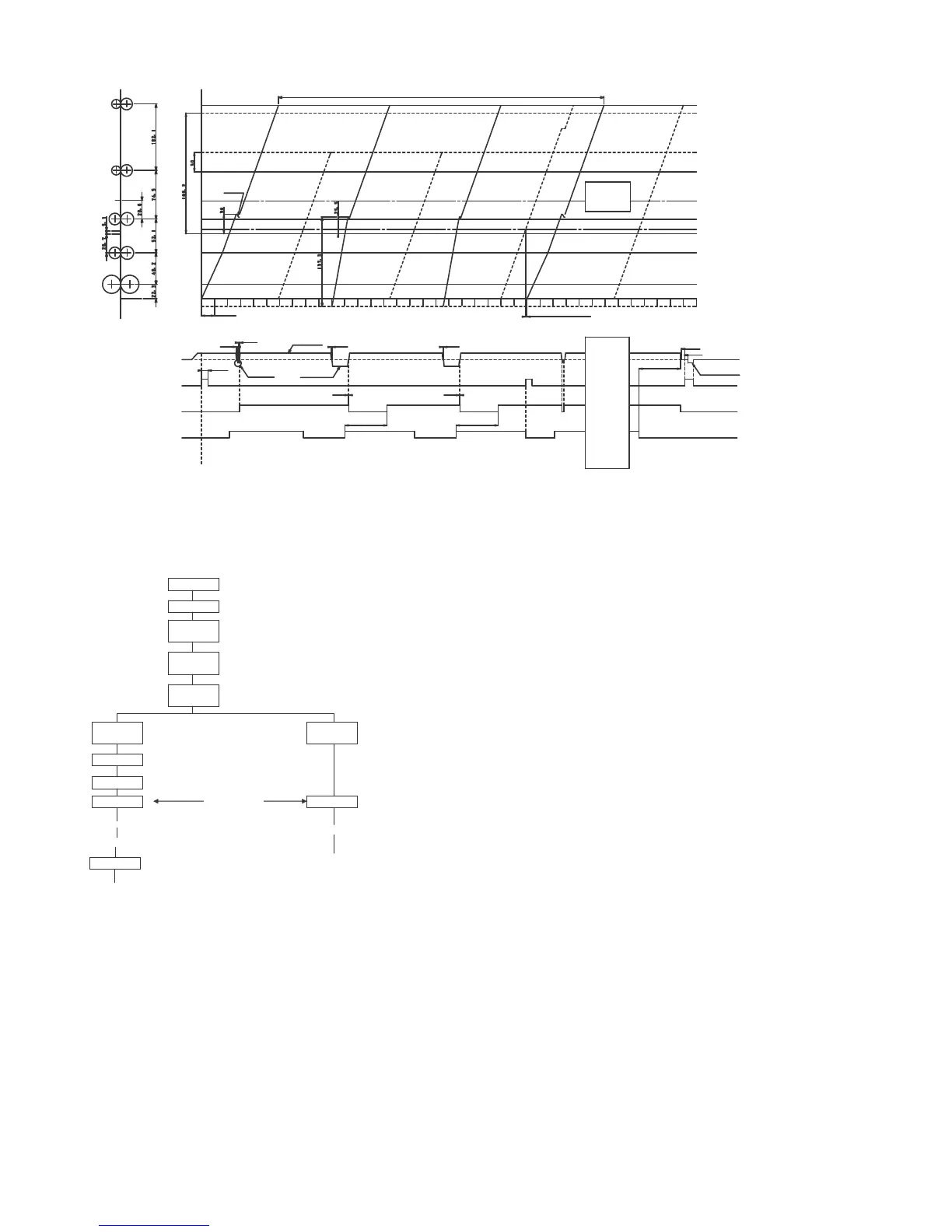

(2)Operation flow

(3)Original transportation

1) When the start button is pushed, the original is picked up from

RSPF tray by pick up roller, and then, transported to image

scanning position.

2) At this time, the CIS Unit is situated under the slit glass to scan

the moving original document.

3) The image on the original is scanned by the CIS Unit while the

document is moving over the slit glass.

4) For duplex original copy, after the original is scanned the original

moves towards the exit tray but does not exit.

A specific time after the lead edge of the original is detected

(depending on paper size) the paper exit rollers reverse rotation

(Switch back) and the original re-enters the paper path at the

upper transport area. Side two of the original is now ready to be

scanned.

The re-entered original (side two) is now passed over the slit glass

and scanned.

5) The original which scan completed is switched back again, then

through the original scanning position, but in this time the image

on original is not scanned, transported and exited.

6) All originals in the set sitting in the document feed tray are

scanned and exited in the same fashion as the first original.

(4)Paper transportation (main body side)

1) The paper is picked up and transported to the PS roller set from

paper cassette by pick-up roller and PS roller. After proper reg-

istration of paper timing, the image on the Primary Transfer Belt

is then transferred to the front side of the paper.

2) After transfer, the paper is separated from the belt and trans-

ported to the fusing section. In the fusing section, toner is

melted into the paper and the paper travels towards the exit

section. In this moment, the paper is not exited completely.

3) When the paper is in the exit section, if a duplex print or copy is

being produced, the paper does not exit into the paper exit tray.

The exit rollers reverse paper direction into the duplex section

where transport roller sets 4 and 5 move the paper to the Regis-

tration rollers. Side one of the original document previously

scanned is now transferred on the paper as it passes the regis-

tration rollers (after correct timing) and moves upward past the

Primary Transfer belt The paper is separated from the Transfer

Belt and moves to the fuser unit. The paper passes through the

fuser unit where the transferred toner to the paper(side 1 of the

original document) becomes melted into the paper by heat and

pressure.

After the image is transferred to the paper, the two sided copy /

print exits into the exit tray with side one facing face down allowing

the rest of the copies / prints to exit in the same order the originals

were placed in the document feed tray of the RSPF.

Reverse pulseReverse pulse

(15mm minutes)(15mm minutes)

50ms50ms

50ms50ms

255mm255mm

50ms50ms

20ms20ms

186.2mm186.2mm

50ms50ms

20ms20ms

186.2mm186.2mm

Clockwise 56mm/sClockwise 56mm/s

CounterclockwiseCounterclockwise

112m/s112m/s

Reverse Reverse

4.5mm Minutes4.5mm Minutes

50ms50ms

70ms70ms

100ms100ms

1000ms1000ms

SPFMSPFM

SPFM tranportation motorSPFM tranportation motor

SPPD1SPPD1

SPF transportation sensorSPF transportation sensor

SRVCSRVC

Reverse clutchReverse clutch

SPUSSPUS

SPF paper feed solenoidSPF paper feed solenoid

SPUFSPUF

SPPD1SPPD1

ON/OFFON/OFF

Reading positoinReading positoin

4.5mm Minute4.5mm Minute

First surfaceFirst surface

Second surfaceSecond surface

Third surfaceThird surface

Second paperSecond paper

24989ms24989ms

Paper feed solenoid is ON by SPPD1_OFFPaper feed solenoid is ON by SPPD1_OFF

Stop at 30mm from SPPD1_ON with feeding the paper. Stop at 30mm from SPPD1_ON with feeding the paper.

Stop at 25.5mm from SPPD1_ON with reverse rotation. Stop at 25.5mm from SPPD1_ON with reverse rotation.

Pickup roller is returned by the reverse rotation Pickup roller is returned by the reverse rotation

after finishing the job JOB. after finishing the job JOB.

Magnetize time : 100ms, Second paper is right after SPPD1_OFF. Magnetize time : 100ms, Second paper is right after SPPD1_OFF.

This is ON at clockwise rotation and This is ON at clockwise rotation and

this is OFF at counter clockwise when the pick up roller is put in. this is OFF at counter clockwise when the pick up roller is put in.

This is OFF in 20ms at the reverse rotation This is OFF in 20ms at the reverse rotation

after the reverse rotation is finished. after the reverse rotation is finished.

This is ON in 185.4mm after SPPD1_ON. This is ON in 185.4mm after SPPD1_ON.

(Only the last paer is OFF in 225.0mm)(Only the last paer is OFF in 225.0mm)

Each load is stopped in 255mm transportation Each load is stopped in 255mm transportation

after the last paper passes SPPD1. after the last paper passes SPPD1.

Loading...

Loading...