VL-PD3U

ADJUSTING THE LCD CIRCUIT

* To make this adjustment, set the backlight switch to the “NORMAL” position.

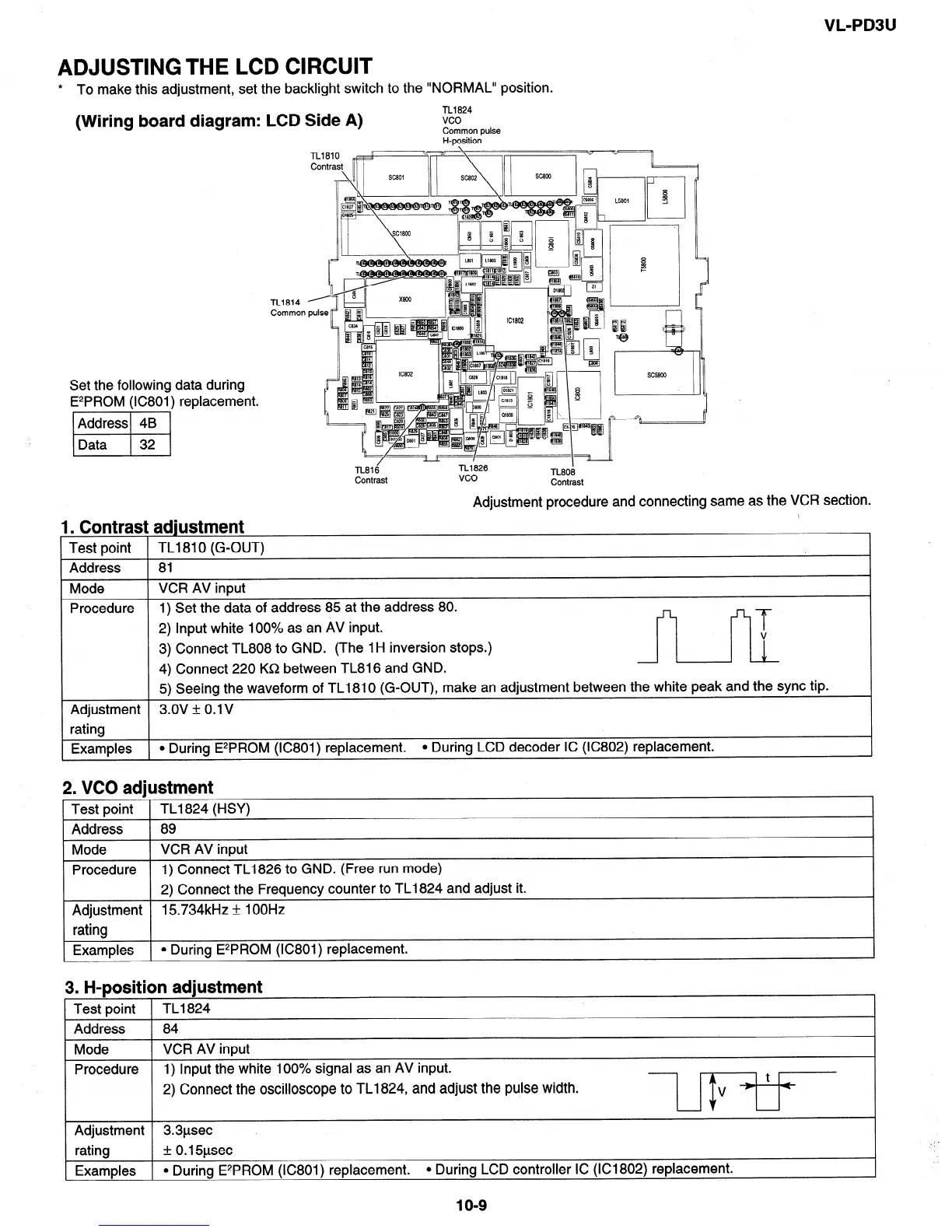

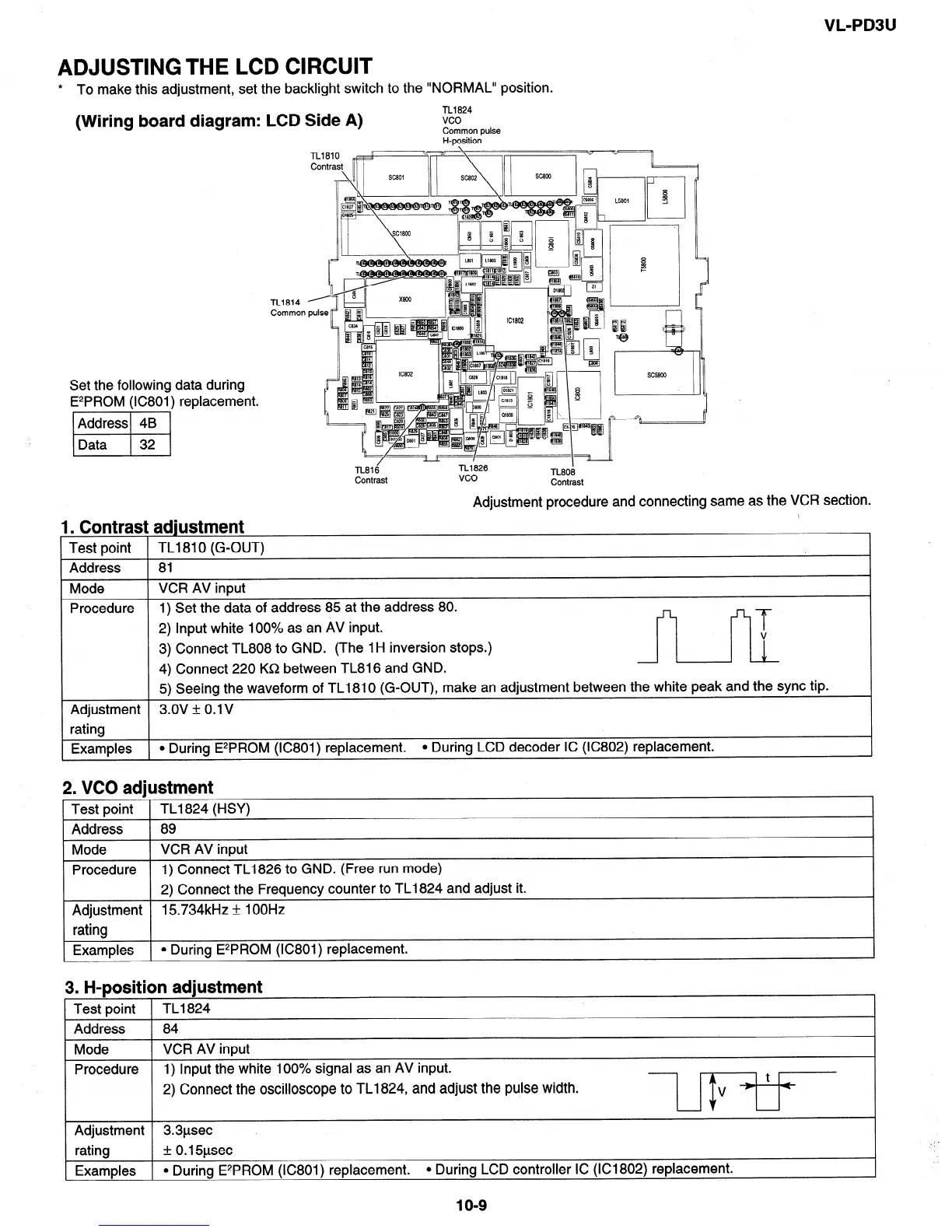

(Wiring board diagram: LCD Side A)

TL1824

vco

Common pulse

H-position

Set the following data during

E2PROM (IC801) replacement.

Address 4B

Data 32

TL1810

Contrast

JYFJT’

L5801

-/-/

TL816

TL1826

vco

Contrast

,r

I

TL808

Contrast

Adjustment procedure and connecting same as the VCR section.

1. Contrast adjustment

1 Test point 1 TL1810 (G-OUT)

1 Address 1 81

Mode VCR AV input

Procedure 1) Set the data of address 85 at the address 80.

2) Input white 100% as an AV input.

3) Connect TL808 to GND. (The 1 H inversion stops.)

4) Connect 220 K&2 between TL816 and GND.

2

5) Seeing the waveform of TL1810 (G-OUT), make an adjustment between the white peak and the sync tip.

Adjustment 3.ov + O.lV

rating

Examples 1 l During E2PROM (IC801) replacement. l During LCD decoder IC (IC802) replacement.

2. VCO adjustment

Test point TL1824 (HSY)

Address 89

Mode

VCR AV input

Procedure

1) Connect TL1826 to GND. (Free run mode)

2) Connect the Frequency counter to TL1824 and adjust it.

Adjustment

15734kHz + 1 OOHz

rating

Examples l During E2PROM (IC801) replacement.

3. H-position adjustment

Test point TL1824

1 Address 1 84

I

Mode VCR AV input

Procedure 1) Input the white 100% signal as an AV input.

t

2) Connect the oscilloscope to TL1824, and adjust the pulse width.

v-) +

Adjustment 3.3psec

% -

rating * 0.15psec

’ I

Examples l During E2PROM (IC801) replacement.

l During LCD controller IC (IC1802) replacement.

1 o-9

Loading...

Loading...