20(77)

2. Structure Characteristics and Working Principle

2.1 Main Functions

STM - W/O series of dual - purpose heater are mainly used to heat up the

mould and maintain its temperature, although they can be also used in other

similar applications. High temperature water or oil return from the mould is

cooled by indirect cooling and then sent to the pipe heater via high - pressure

pump for heating to a constant temperature. This unique design allows user to

choose between water and oil as heat transfer medium. With our optimised

design, the OMRON temperature controller can maintain an accuracy of ±1℃.

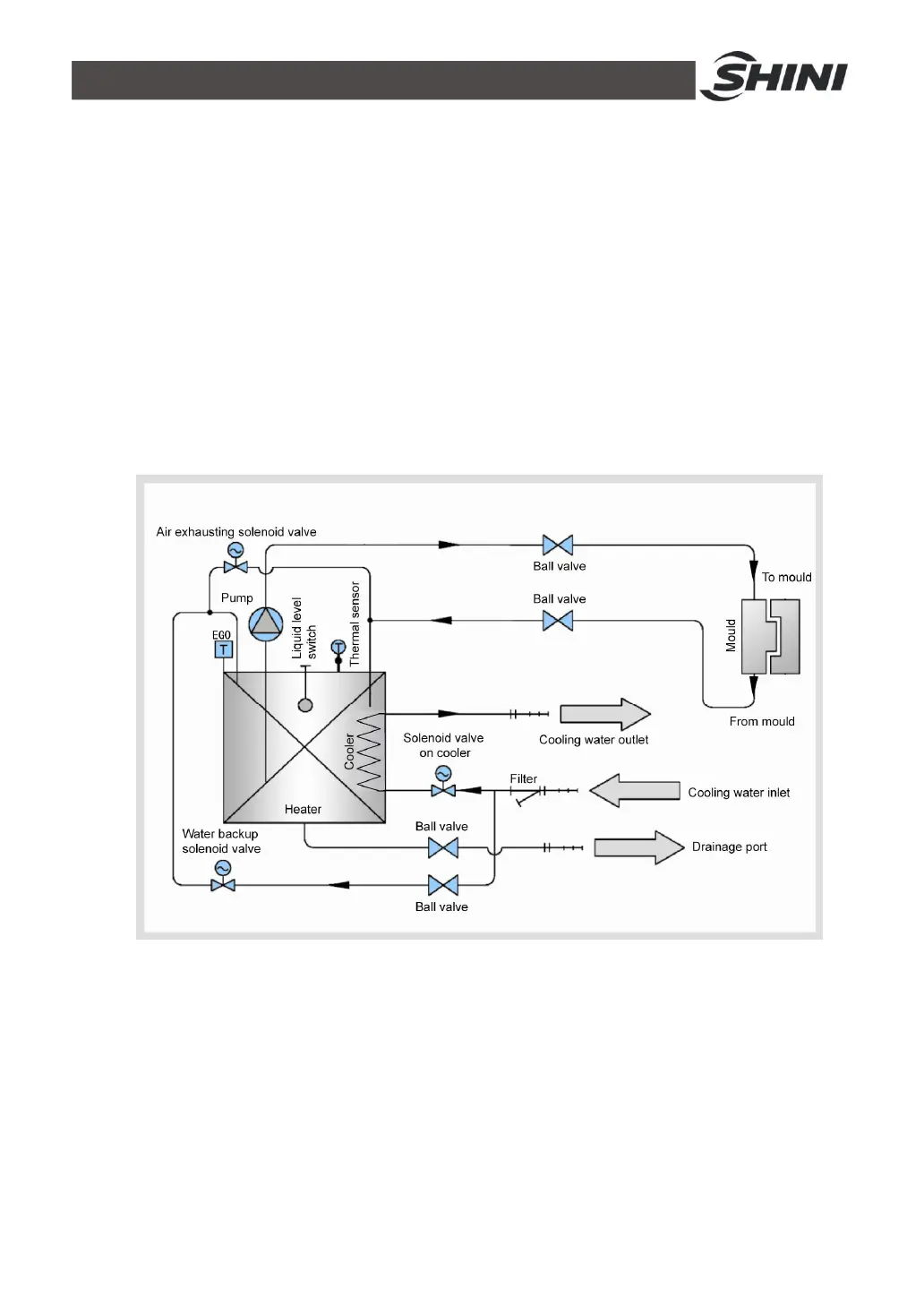

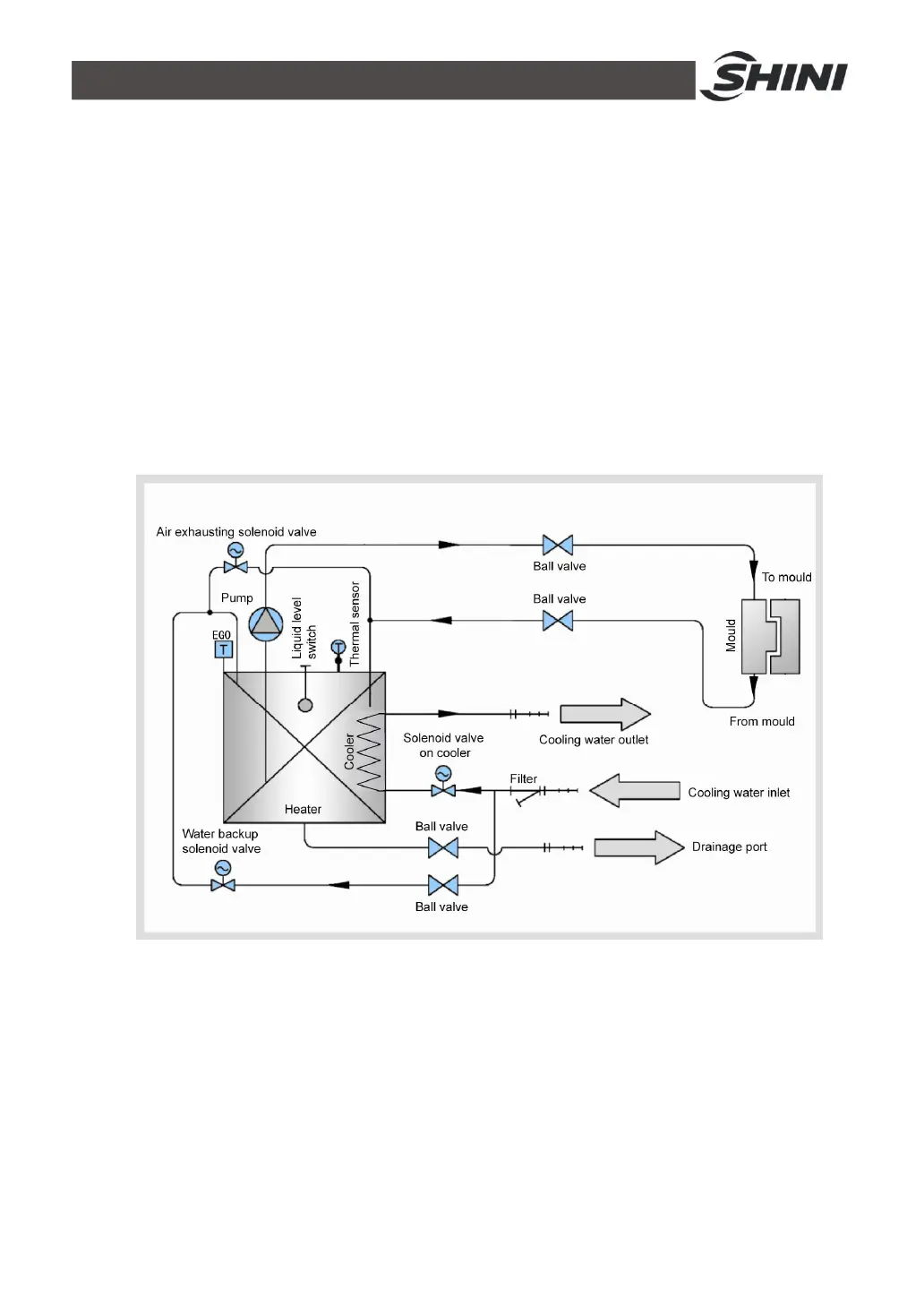

2.1.1 Working Principle

Picture 2-1:Working Principle

High temperature water returns to the machine and then be pressured by pump

to the heater. After being heated, water will be forced to mould and continue the

circle. In the process, if the temperature is too high, the system will activate the

solenoid valve to let cooling water cool down the temp. directly till the water

temp. is down to the system requirement. If the temp. keep rising and reach to

the set point of EGO, the system will alarm and stop operation. The system will

have low pressure alarm and stop working if cooling water pressure doesn’t

reach set point.

Loading...

Loading...