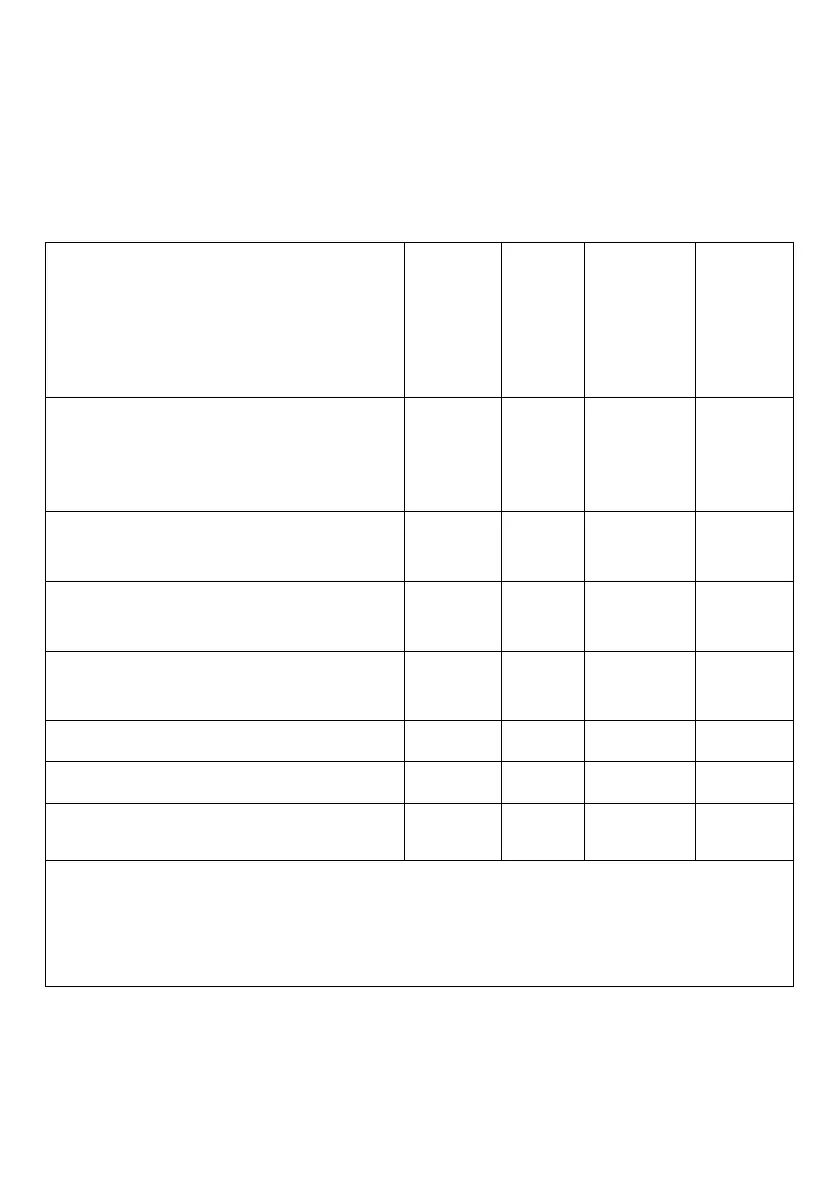

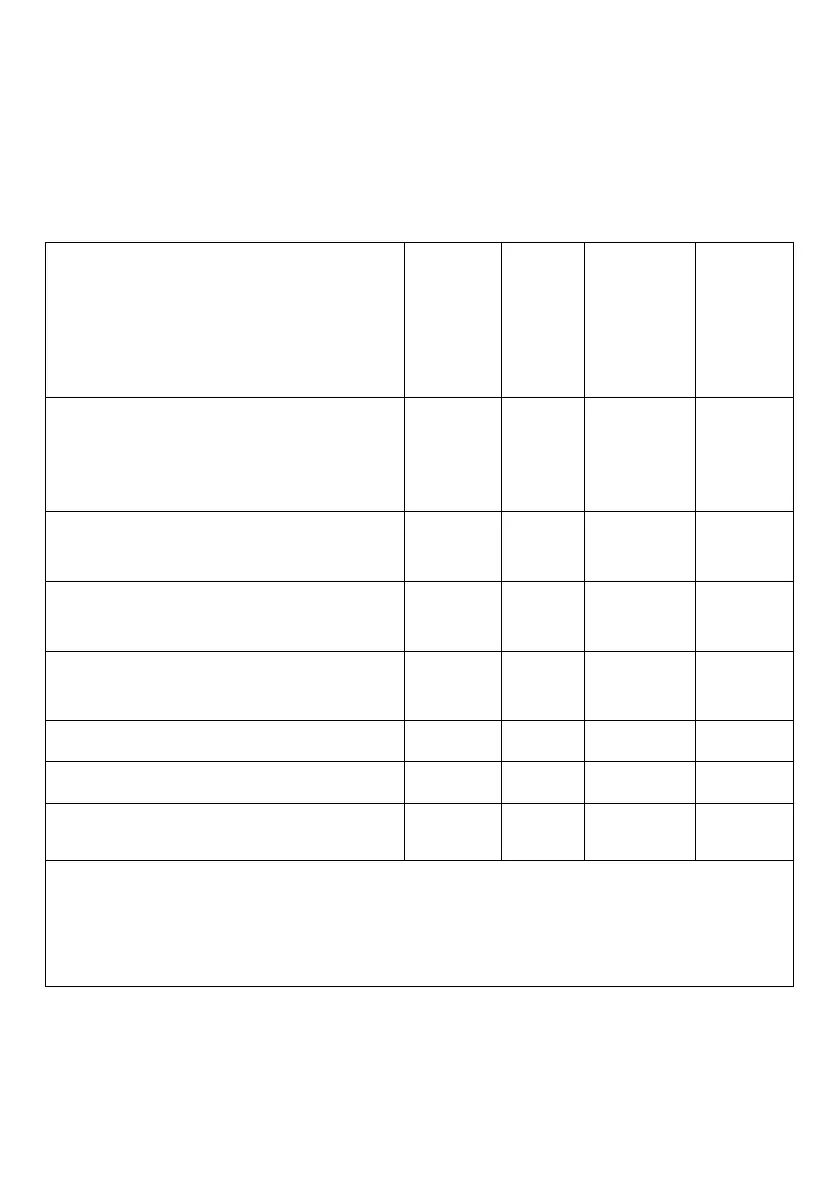

8. MAINTENANCE

8.1. Schedule of maintenance

The tool's maintenance (M) is subdivided into 4 groups depending on

an operation interval and is presented in the table below.

Cleaning of the taper joining

thread, the acoustic transducer, the

pressure gauge, the face panel and

the body.

Flushing and lubricating the

solenoid valve assembly

1)

Flushing and lubricating the

manual valve

Cleaning of the interface slot

Replacement of sealing rings

Notes: 1) maintenance work is carried out by a service center of the

"SIAM" company or by certified specialists of the Company.

It is possible to replace the rubber ring of the exhaust valve (pos. 15 p.5) by

direct users

Loading...

Loading...