Mounting: D

6.2 Mounting the FlexFix bracket

Lateral and rear mounting with the FlexFix bracket

Mounting type Description

On the side With the M5 screw through the FlexFix bracket on the machine or profile

frame. A screw nut or threaded hole is required on the machine or profile

frame (!).

With the M5 screw through the FlexFix bracket on the profile frame. Two slid‐

in

g nuts are required on the profile frame (").

On the back With the M5 screw through the FlexFix bracket on the machine or profile

fr

ame. A screw nut or threaded hole is required on the machine or profile

frame (§).

1. After mounting the FlexFix brackets, screw the sender and receiver into the FlexFix

br

ackets from the front and align the sender and receiver.

NOTE

T

he safety light curtain can only be screwed in when both FlexFix brackets are in align‐

ment.

Recommendation:

1. Only hand-tighten the screws on the FlexFix brackets at first.

2. Align the two FlexFix brackets. To do this, place a straightedge or spirit level, for

example, at the screw mounting surfaces of the FlexFix brackets that are not being

used.

3. Tighten the screws.

2. Use an M5 screw to fix the position of the sender and receiver in the FlexFix

br

acket.

Mounting:

E

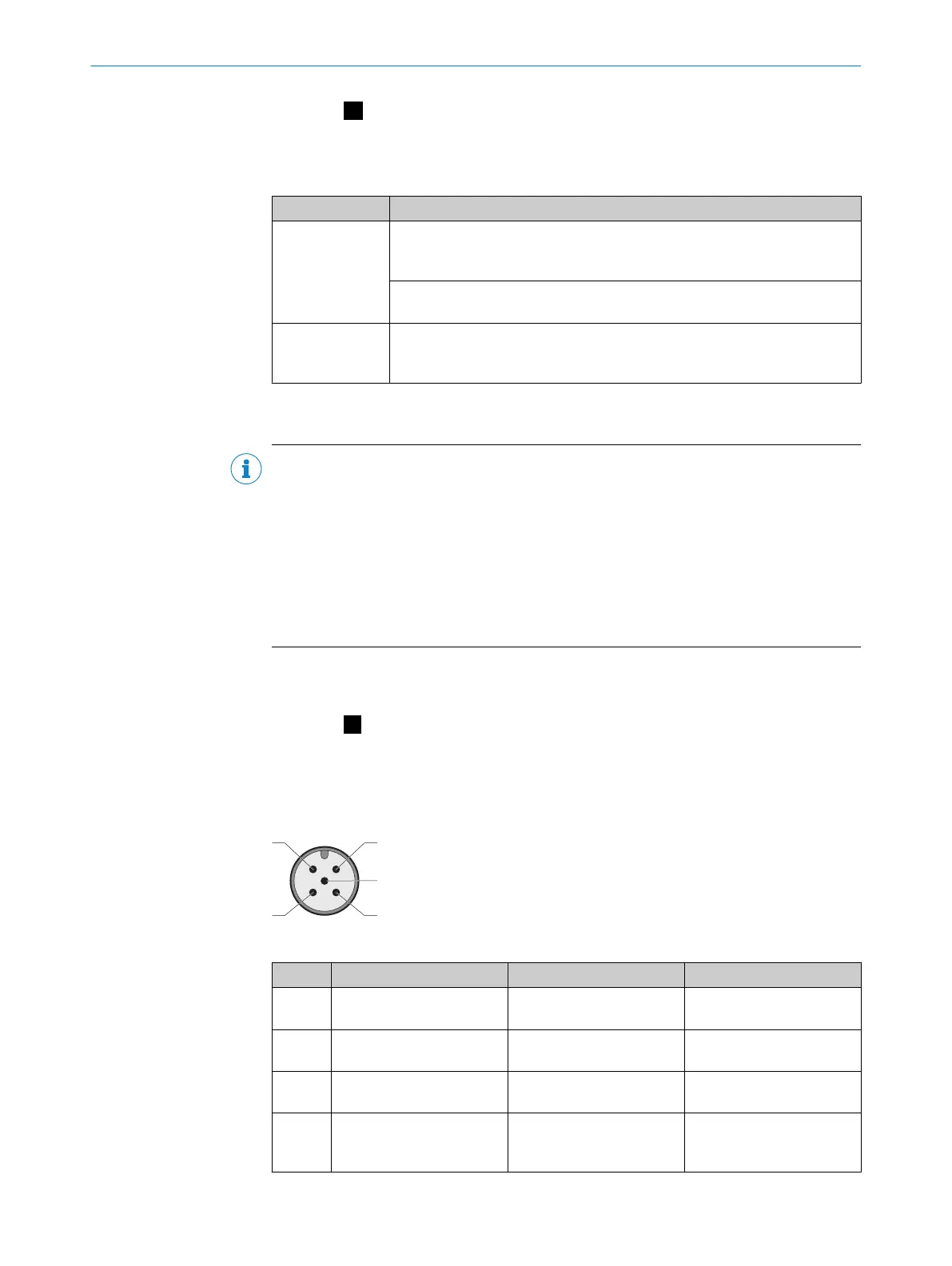

7 Pin assignment

System connection (M12, 5-pin)

System connection pin assignment (male connector, M12, 5-pin)

Pin Wire color

1)

s S

ender r Receiver

1 Brown +24 V DC (voltage supply

in

put)

+24 V DC (voltage supply

input)

2 White In2 (laser alignment aid

button)

OSSD1

3 Blue 0 V DC (voltage supply

input)

0 V DC (voltage supply

input)

4 Black In1 (laser alignment aid

s

witch/cascade synchro‐

nization input)

OSSD2

MOUNTING INSTRUCTIONS

8022020/ZYO3/2018-05-15 | SICK M O U N T I N G I N S T R U C T I O N S | deTec4

15

Subject to change without notice

Loading...

Loading...