30

8018429/1DWP/V3-0/2022-06| SICKADDENDUM TO OPERATING INSTRUCTIONS | GMS840

Subject to change without notice

8 TECHNICAL DATA

8.2 Enclosure specifications

8.3 Ambient conditions

8.4 Gas connections

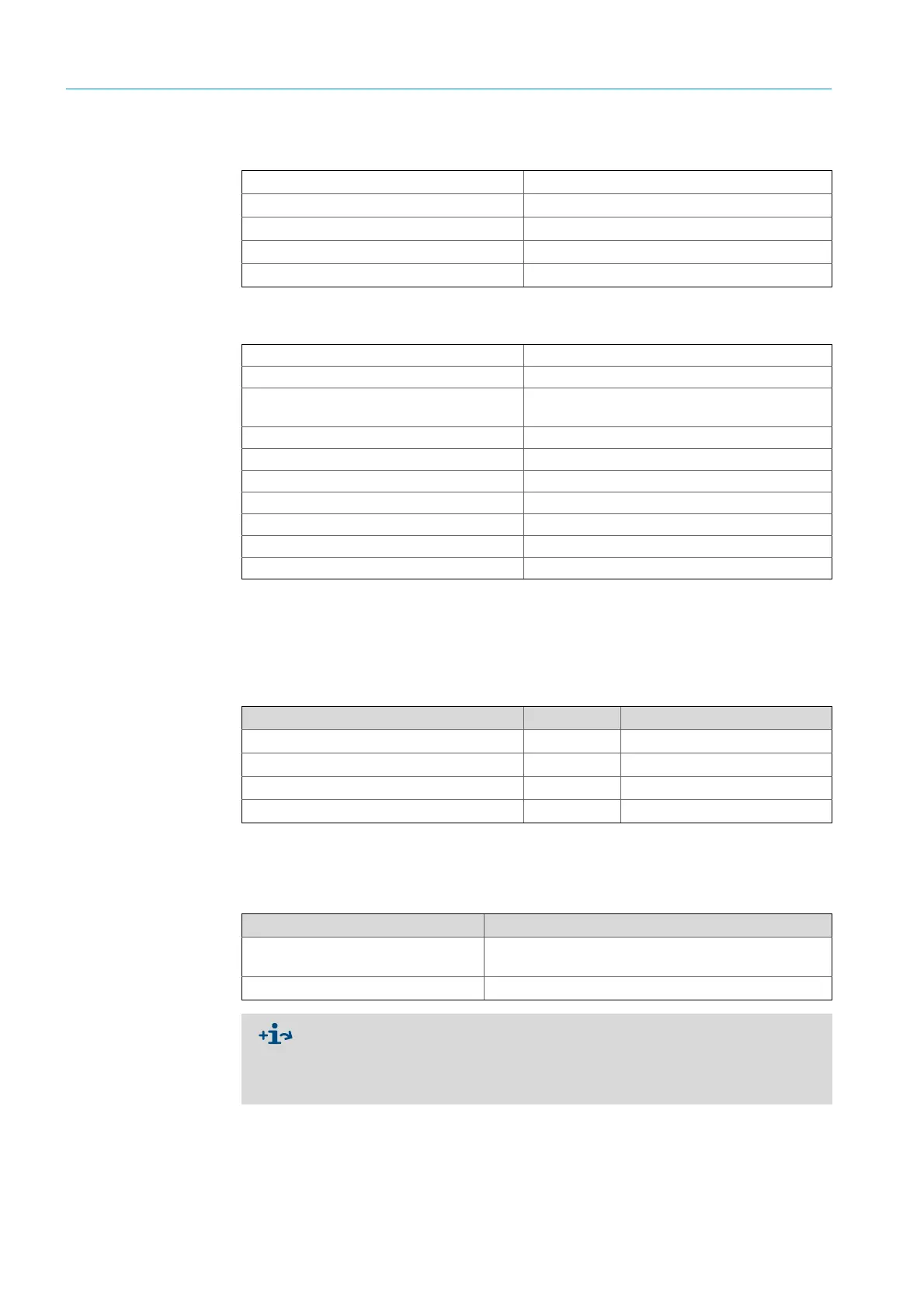

Version

Approval conditions

For GMS841 (ATEX/ IECEx)

Design: Closed steel sheet enclosure

Degree of protection: IP 66 (Nema 4X)

Dimensions: See 27

Weight: Depending on equipment: max. approx. 30 kg

Identification for GMS84x: see “Product identification”, page 9

Atmospheric influences: Only for use indoors

Allowable contamination: Degree of contamination 2

[1]

[1] Dry and wet contamination that can be electrically conductive.

Fitting position (allowable offset):

Only install the enclosure horizontally (cover opens

downwards or upwards).

Geographic height at installation location: Max. 2000 m

Allowable oscillations (amplitude):

[2]

[2] Observe DIN 15267-3, DIN EN 60068-2-26; as well as specifications for built-in Analyzer modules.

0.035 mm in range 5 … 59 Hz

Allowable vibrations (acceleration):

[2]

5m/s

2

in range 59 … 160 Hz

Jolts: ≤ 15 g over 11 ms

[3]

[3] Shock test in accordance with DIN EN 60068-2-27.

Relative humidity: 10 … 95%, non-condensing

Ambient temperature during operation: +5 … +45 °C (41 … 113 °F)

Transport /storage temperature: –10 … +70 °C (14 … 158 °F)

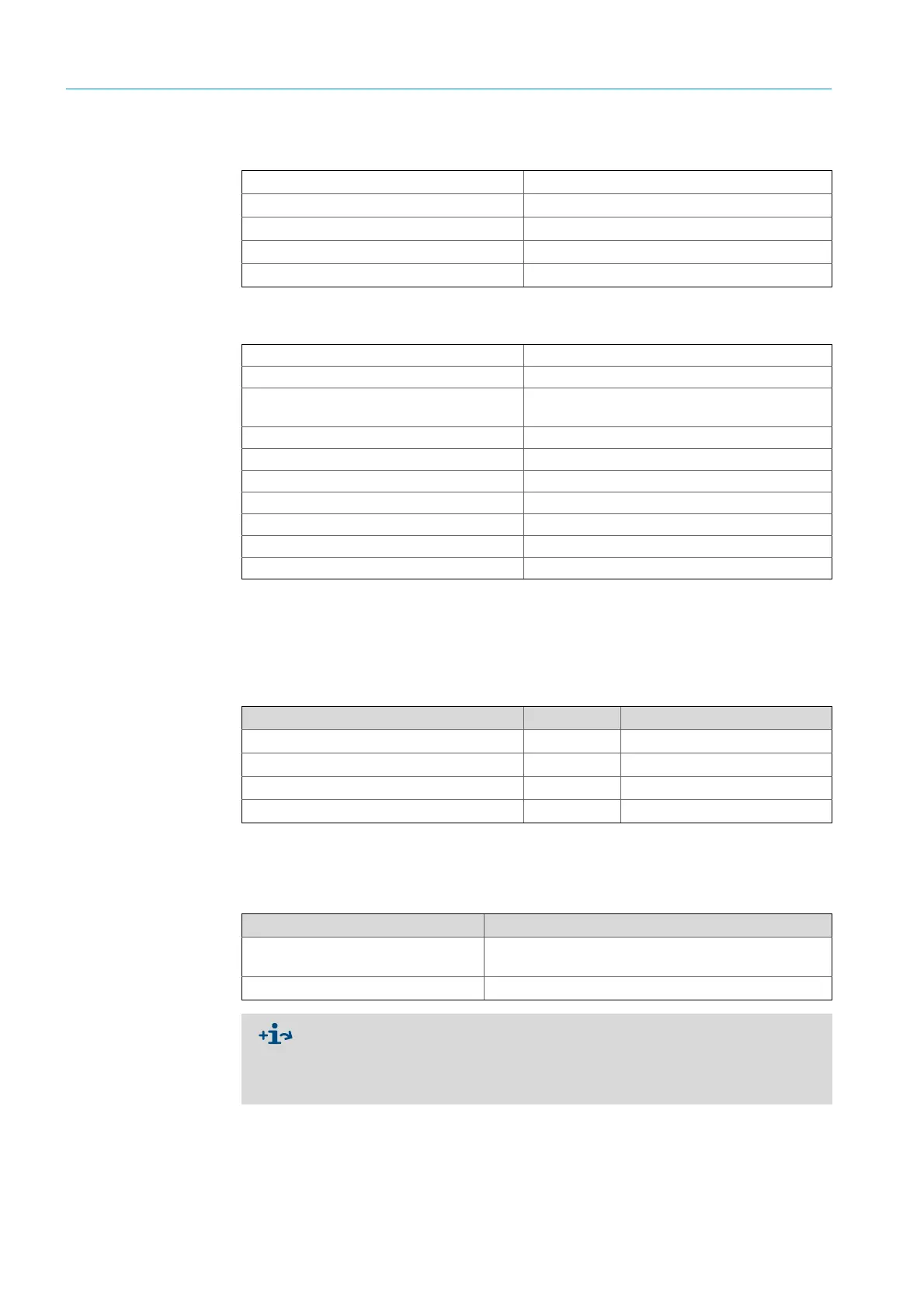

Description Material Suitable for

Inner thread G ¼"

[1]

: Stainless steel Screw-in screw fittings

Plastic clamping ring screw connection PVDF Hose 6x1 mm

Swagelok 6 mm Stainless steel Metal tube with 6 mm outer Ø

Swagelok ¼“ Stainless steel Metal tube with ¼“ outer Ø

[1] Standard version.

Parameter Allowable value

Sample gas pressure in sample gas

line:

–500 … +1000 hPa (–0.5 … +1.0 bar)

Sample gas volume flow: Max. 100 dm

3

/hour

● Sample gas connection positions, see “Dimensions, fitting position and

connections”, page 27

● Sample gas connections function → “GMS800 Series” Operating Instructions.

● Other sample gas specifications (pressure, volume flow etc.) → Addendum to

Operating Instructions for the Analyzer modules fitted.

Loading...

Loading...