The safety laser scanner has 4 M5 threaded holes on the back. If you are able to drill

t

hrough the mounting surface from the rear, you can mount the safety laser scanner

directly using these threaded holes.

b Use either the rear 1 or the side 2 M5 threaded holes for direct mounting.

b

Use all four rear or all four side M5 threaded holes for direct mounting, so that the

values given in the data sheet for vibration and shock resistance are achieved.

b

Maximum depth of thread engagement: 7.5 mm.

b

Tightening torque: 4.5 Nm to 5.0 Nm.

6 Connection overview

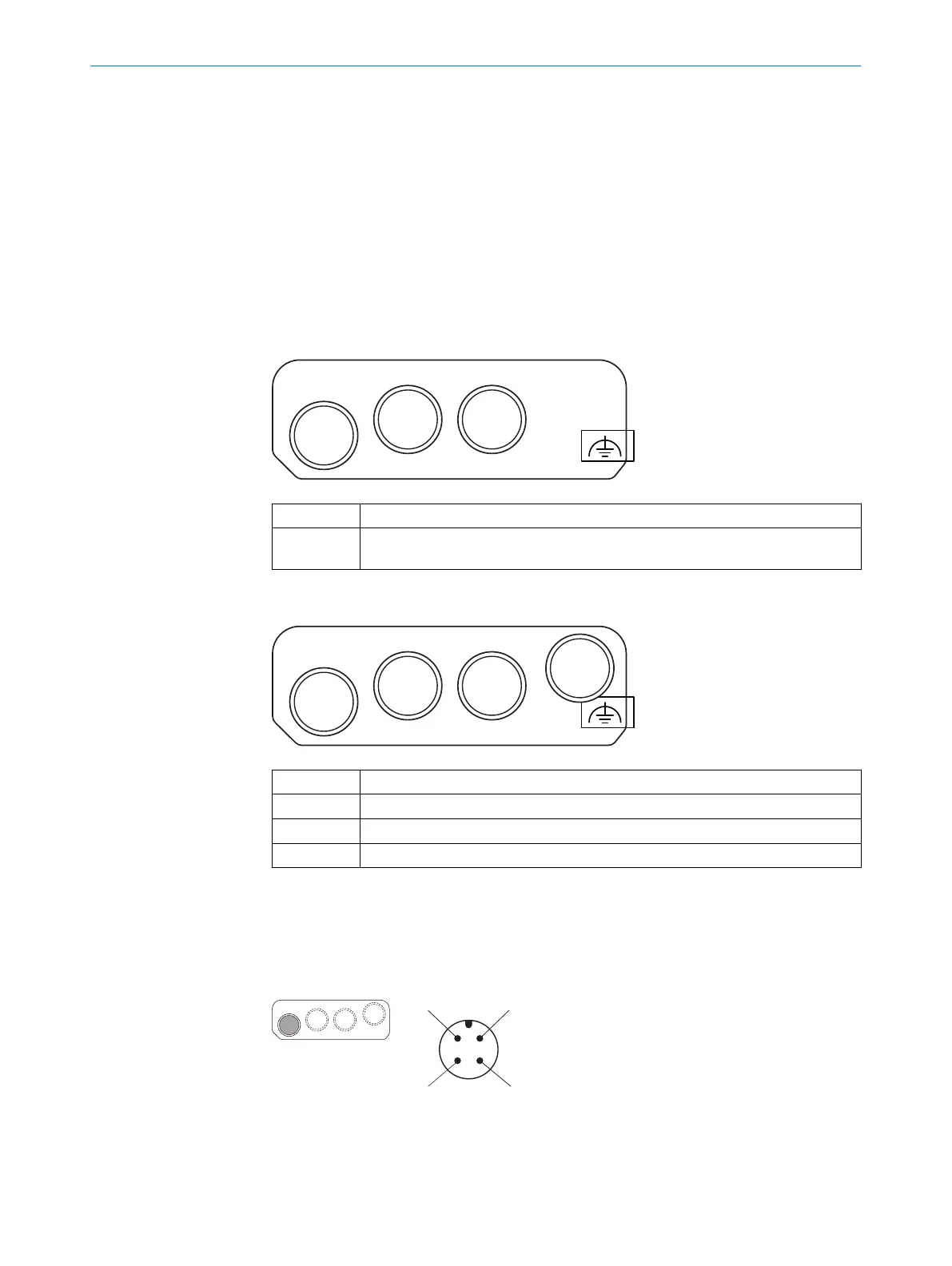

MICSX-BANNZZZZ1 (part number: 2086102)

XD1 Voltage supply

XF1, XF2 Ethernet for safety-related data communication, data output, configuration and

dia

gnostics

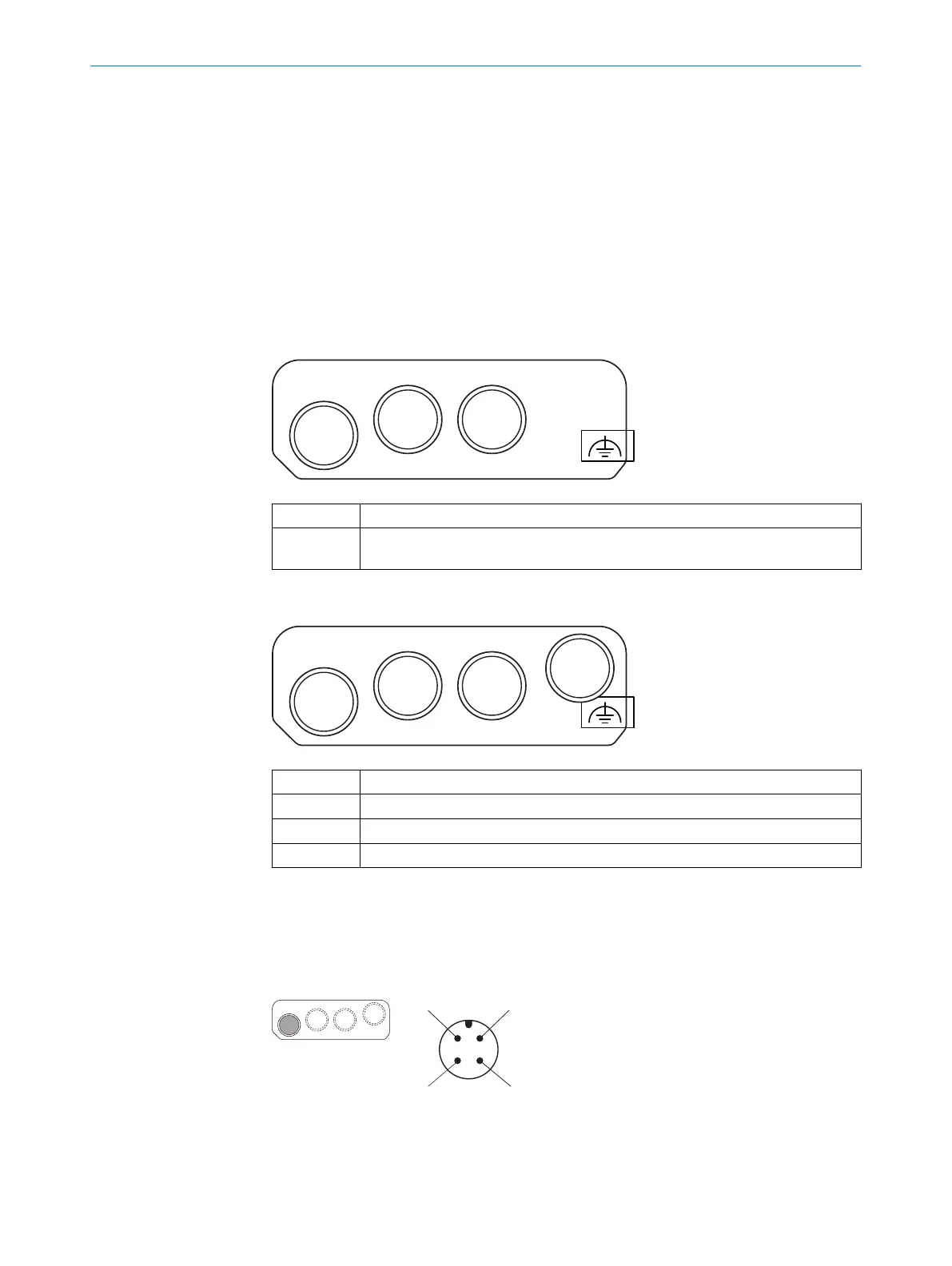

MICSX-BANNEZZZ1 (part number: 2081021)

XD1 Voltage supply

XF1 Ethernet for EtherCAT IN

XF2 Ethernet for EtherCAT OUT

XF3 Ethernet (not safety-related)

7 Pin assignment

7.1 Voltage supply (XD1)

Male connector, M12, 4-pin, A-coded.

MOUNTING INSTRUCTIONS

8020210/16V7/2020-03-16 | SICK M O U N T I N G I N S T R U C T I O N S | microScan3 – EFI-pro, microScan3 – EtherCAT®, microScan3 – PROFINET (M12),

micr

oScan3 – EtherNet/IP™

13

Subject to change without notice

Loading...

Loading...