10/80

Siemens Building Technologies Commissioning Guide CM1G5192en

HVAC Products 4 EMC-compatible installation of SED2 26.02.2003

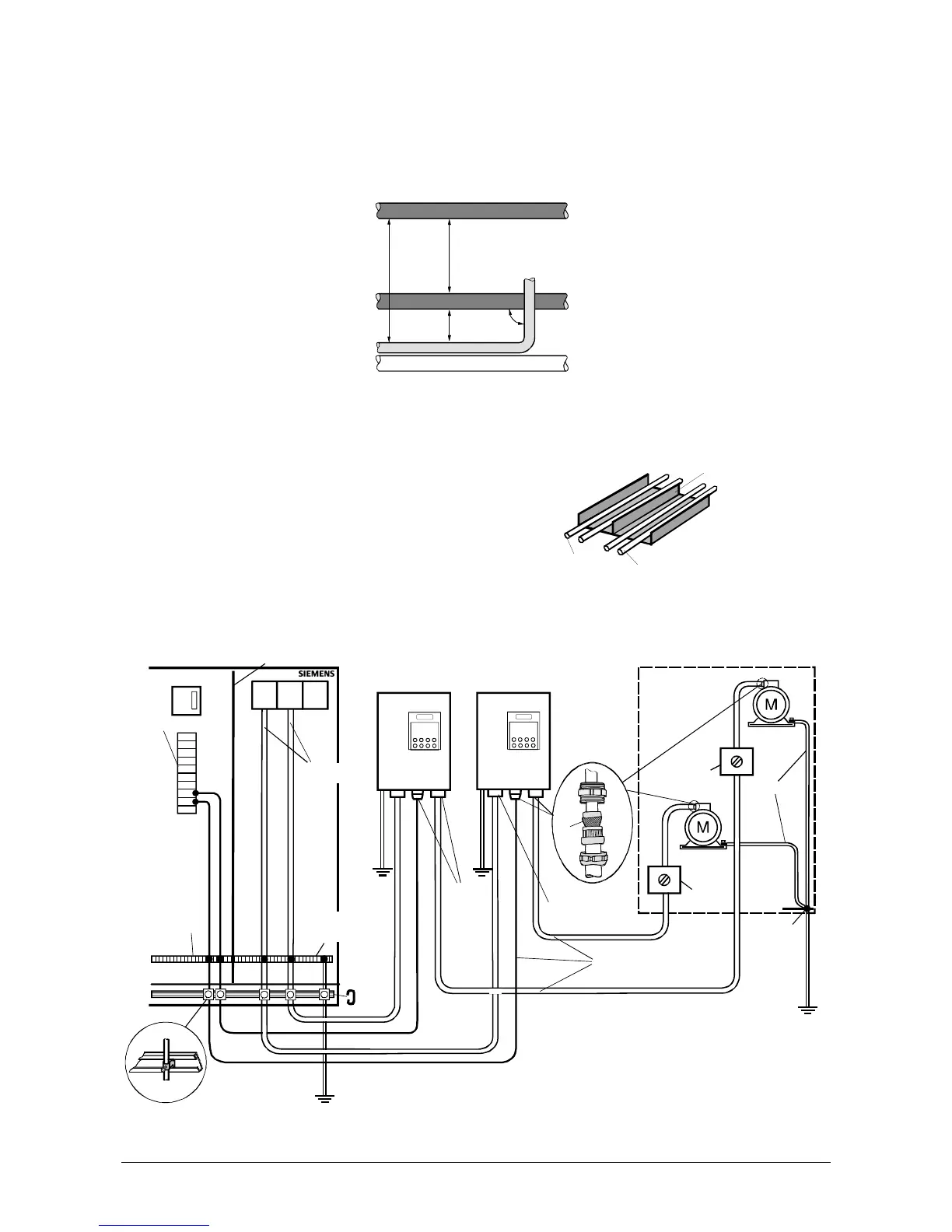

4.4.2 Routing of cables

• Lay cables of different power sections, such as control, mains and motor cables, separately

• Avoid undesired coupling caused by parallel running control, power and motor cables

• Lay control, mains and motor cables separately, in separate cable ducts at a distance of at least 200 mm (see

illustration below). If cables must be crossed, run them at an angle of 90° if possible

90°

> 40 cm > 20 cm

> 20 cm

5192Z37en

Motor cable

Mains cable

Signal cable

Signal / control cable

• Keep cables to motors as short as possible, generally not exceeding 25 m

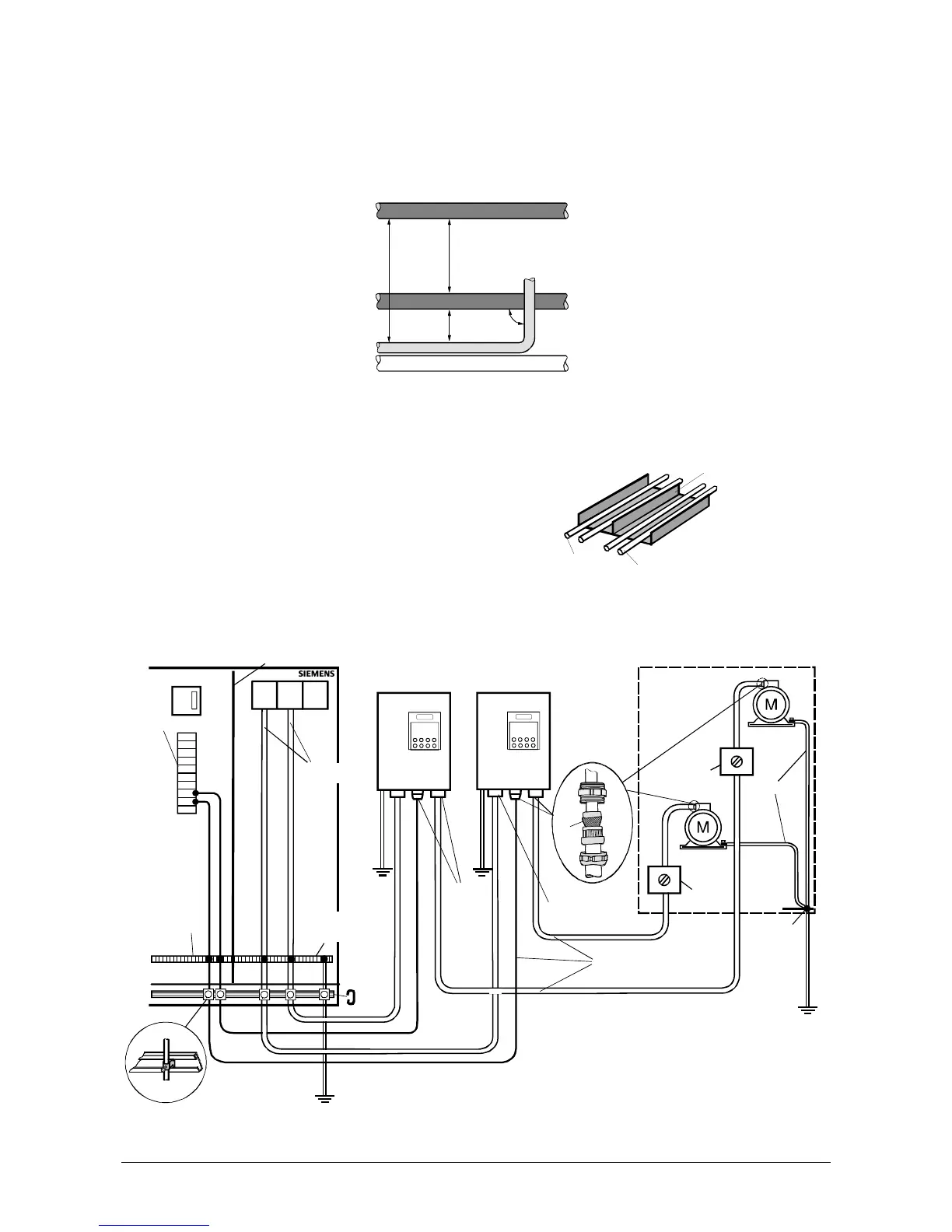

• If possible, lay external cables in sheet metal ducts or on metal carriers. The metal cable duct or carrier should

be earthed and its individual parts should be galvanically connected

• If it is not possible to run control, power and motor ca-

bles separately in separate cable ducts or cable carri-

ers, the cable duct or carrier must at least have metallic

galvanically conductive partitions

Metal partition

5

1

9

2

Z

4

5

e

n

Motor cable

Signal and

control cables

IP 54: Example of EMC-compatible installation and wiring of the SED2

BMS

F1 F2

III III

SED2 / IP54

SED2 / IP54

*

*

*

*

Connection and

potential

equalization rail

Extract air

Supply air

Extract airSupply air

Metal

cable glands

Strain

relief rail

Min.16 mm

2

Control cabinet

Monoblock

Metal partition

I/O modules

Plastic cable gland

Power Supply

cable unshielded

Connection

terminals

Shielded cables

Potential

equalization

Metal

cable gland

Shielding

Service

switch

Service

switch

5192Z33en

* All potential equalization cables must have

a cross-sectional area of at least 16 mm

2

Loading...

Loading...