Supplements to ET 200SP documentation

2.5 I/O module manuals

Product information on the documentation of the ET 200SP distributed I/O system

Product Information, 02/2021, A5E03799595-BG

59

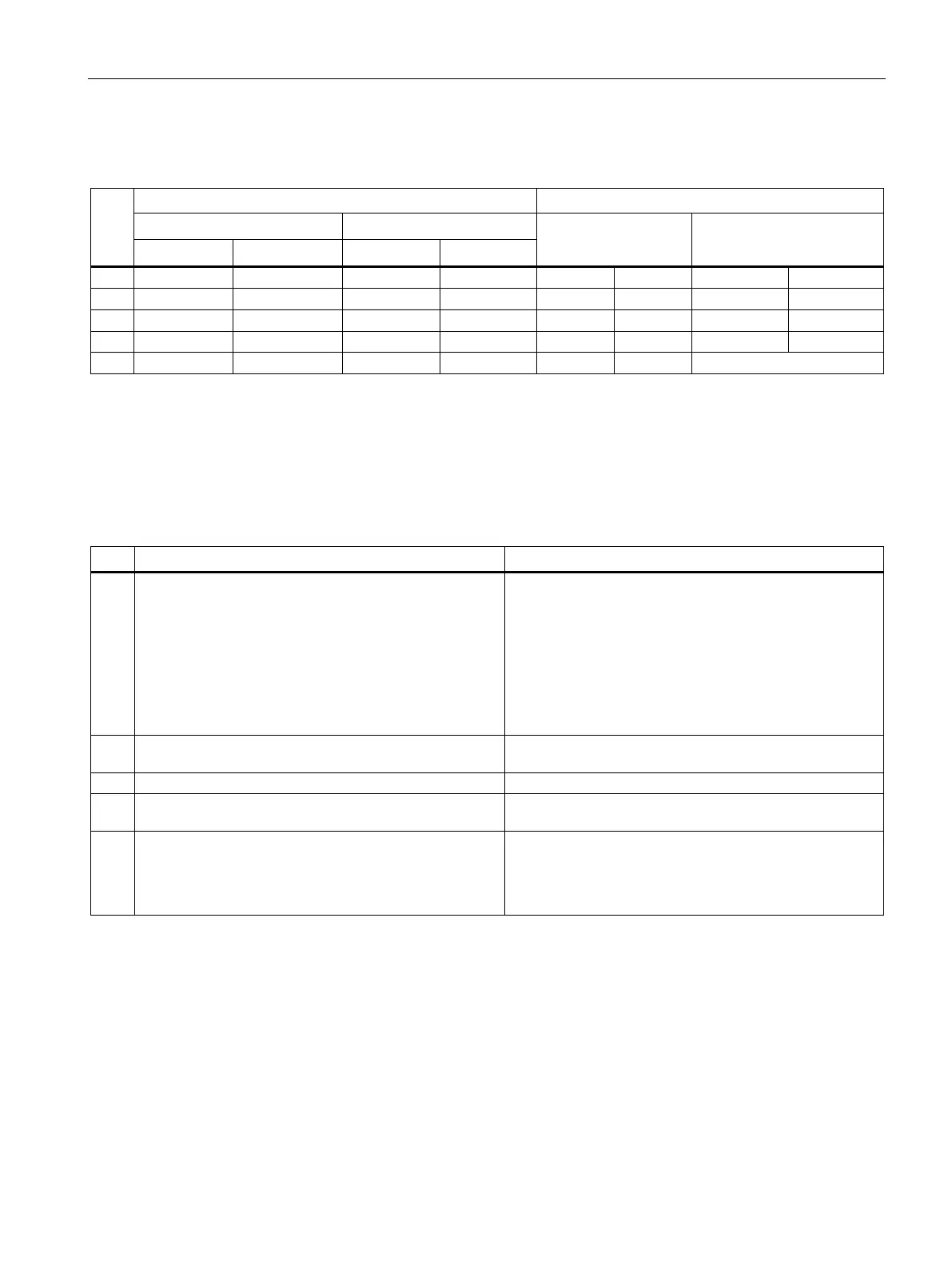

Table 2- 9 Measured values in case of a line break in a TC measurement with enabled reference junction (reference chan-

nel) depending on enabled diagnostic information

Case

Reference channel TC channel

3

3

2

3

3

4

4

3

3

2

3

3

4

4

3

3

3

3

1.3

*3

* Parameter assignment not relevant

The wire break test can only be disabled via data set 237.

Diagnostics is suppressed in the event of a reference channel error.

Channel with line break

4

Measured value taken from the reference channel

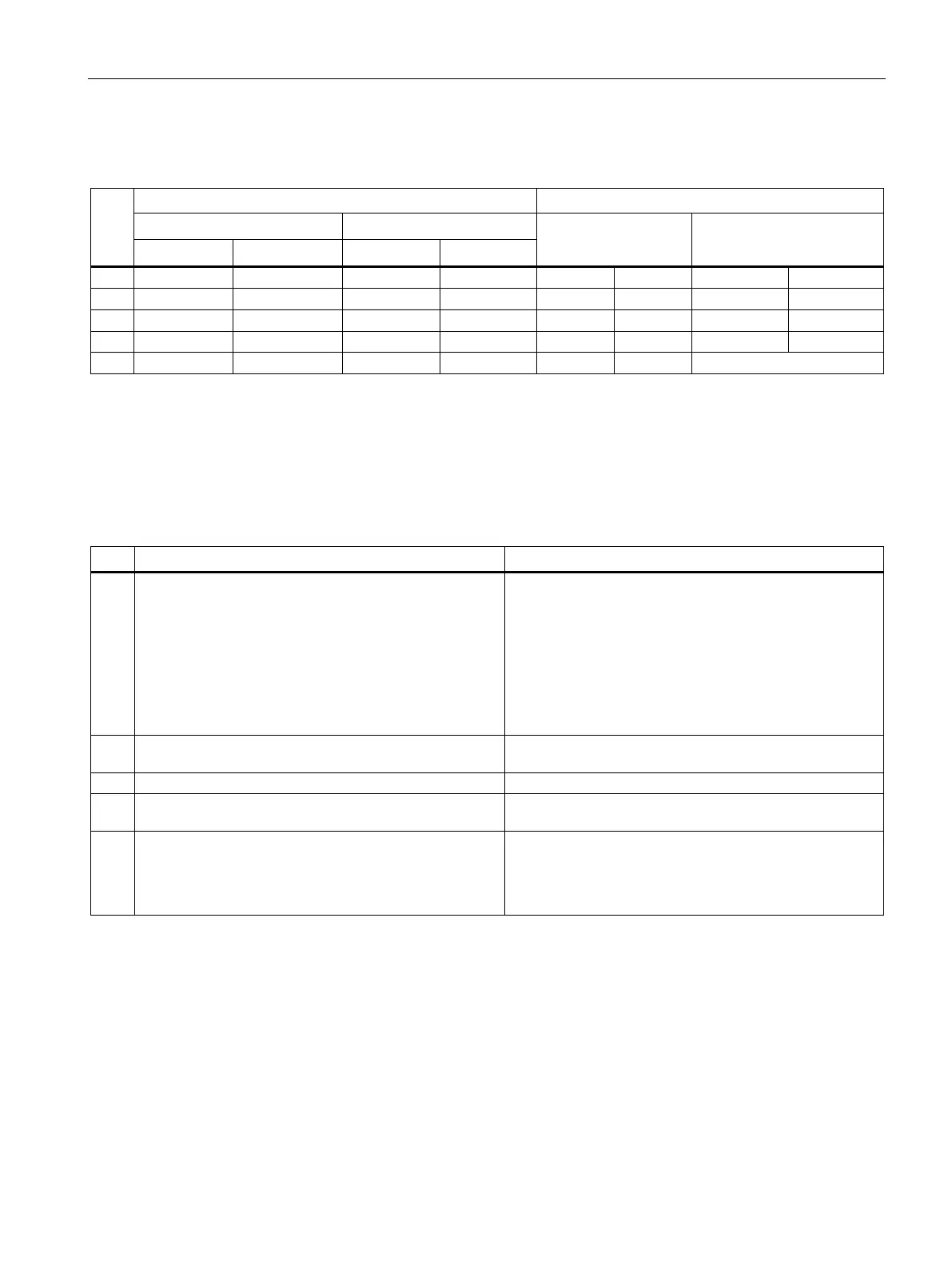

Explanations of the cases:

The "wire break" diagnostics is reported.

This has a higher priority than the "Underflow" diagnos-

tics.*

The "Reference channel error" diagnostics is reported if

this is enabled. Where own pending diagnostic infor-

mation ("overflow" or "underflow") is reported as out-

going. Wire break diagnostics is detected independently

of the measured value and has the same priority as the

"Reference channel error" diagnostics. Both items of diag-

nostic information can be pending simultaneously. The

measured value of the reference channel (RTD channel) is

adopted for the TC channel. The validity of the measured

value of the TC channel is irrelevant.

No diagnostics reported. A wire break check is carried

out (i.e. test current flows).*

Behavior corresponds to case 1.

Measured values are in the valid measuring range

The "wire break" diagnostics is reported.*

Measured values are in the valid measuring range

No diagnostics reported. A wire break check is carried out

(i.e. test current flows).*

Measured values are in the valid measuring range

No "wire break" diagnostics is reported. No wire break

check is carried out (i.e. no test current flows). This is

required to calibrate thermocouples, since the test current

necessary for a wire break check leads to measurement

errors during calibration.*

* Channel with wire break

Loading...

Loading...