Faults and Alarms 10.99

6SE7087-6KP50 Siemens AG

12-24 Operating Instructions SIMOVERT MASTERDRIVES

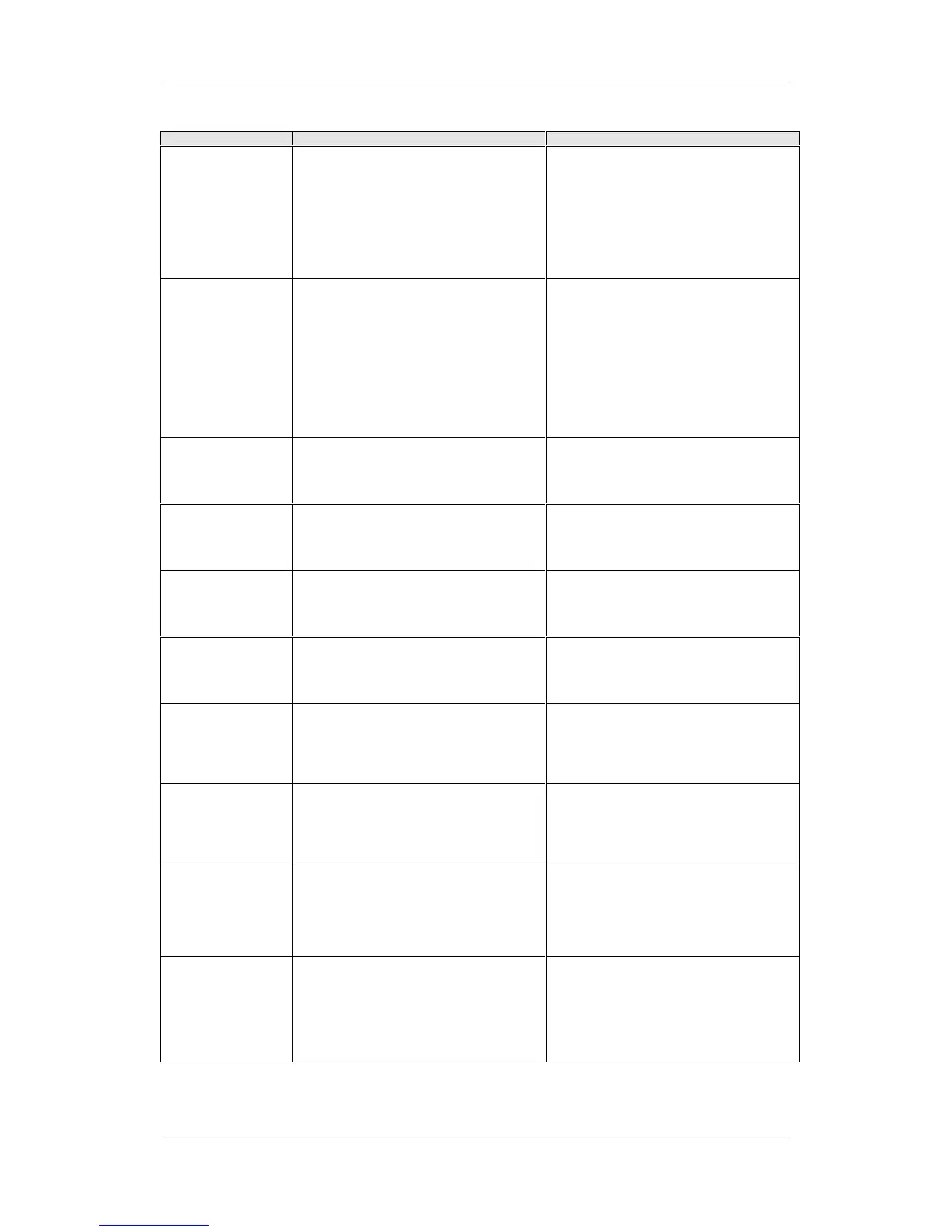

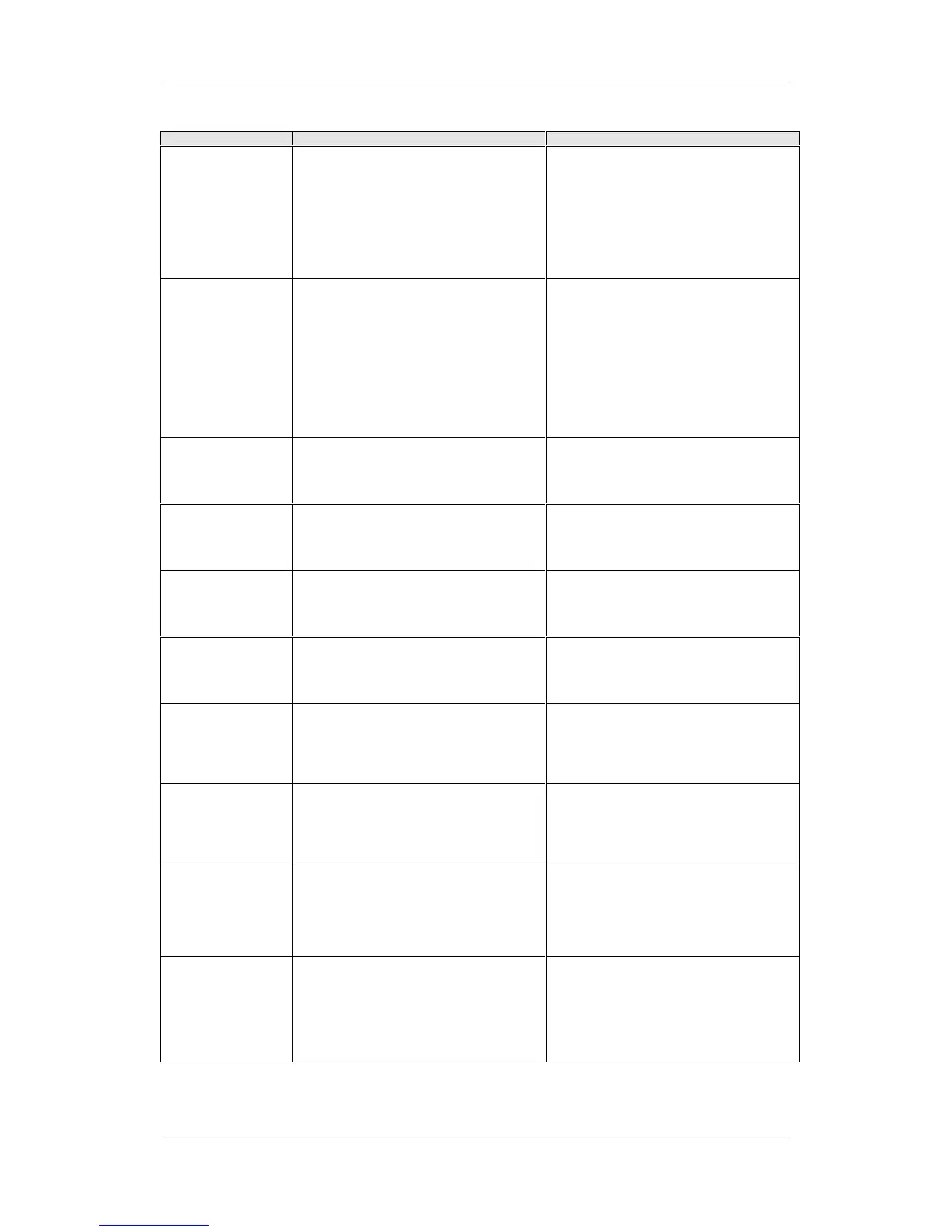

Number / Alarm Cause Counter-measure

A155

Reset in slave axis

active

The "reset" [RST] control signal is active in the

slave axis required by the master axis. A slave

axis with an active reset cannot be used by the

master axis (M7 only, not significant for the

F01 technology option.

Effect:

NC program execution is inhibited or aborted,

the axis is brought to a standstill via the

deceleration ramp.

Cancel the "reset" [RST] control signal in the

slave axis.

A156

Axis type (MD1) of

slave axis not allowed

An NC program was started in which a slave

axis is defined as a roll feed axis type (M7

only, not significant for the F01 technology

option).

The warning is output in the master axis and

indicates an illegal axis type in the slave axis.

Effect:

NC program execution is inhibited or aborted,

the axis is brought to a standstill via the

deceleration ramp.

Axes defined as roll feed axes can only be

used in dedicated NC programs.

A160

Setup speed = 0

The value entered in level 1 or level 2 for the

[F_S] velocity level in setup mode is zero.

Effect:

The axis movement is inhibited.

Define a permissible velocity level for level 1

and/or level 2. The permissible value range is

between 0.01 [1000*LU/min] and "traversing

velocity - maximum (machine data 23).

A161

Reference approach

velocity = 0

The velocity value entered for "reference point

- approach velocity" (machine data 7) is zero.

Effect:

The axis movement is inhibited.

Enter a permissible value for the approach

velocity. The permissible value range is

between 0.01 [1000*LU/min] and "traversing

velocity - maximum (machine data 23).

A162

Reference point -

reducing velocity = 0

The velocity value entered for "reference point

- reducing velocity" (machine data 6) is zero.

Effect:

The axis movement is inhibited or stopped.

Enter a permissible value for the reference

point -reducing velocity. The permissible value

range is between 0.01 and 1000

[1000*LU/min].

A165

MDI block number not

allowed

The MDI block number [MDI_NO] specified in

the control signals is greater than 11.

Effect:

The axis movement is inhibited.

Define an MDI block number [MDI_NO]

between 0 and 10.

A166

No position has been

programmed in MDI

mode

The "start" [STA] control signal was activated

in MDI mode without initially transferring a

positional value to the selected MDI block.

Effect:

The axis movement is inhibited.

Use the correct sequence: data transfer

followed by axis start.

A167

No velocity has been

programmed in MDI

mode

The "start" [STA] control signal was activated

in MDI mode without initially transferring a

velocity value to the selected MDI block.

Effect:

The axis movement is inhibited.

Use the correct sequence: data transfer

followed by axis start.

A168

G91 not allowed with

MDI on the fly

G91 (incremental dimensions) was defined in

the MDI block as the 1st G function for the

MDI on-the-fly function.

Effect:

The axis movement is inhibited or stopped via

the deceleration ramp.

The MDI on-the-fly function only allows G90

(absolute dimensions) as the 1st G function.

A169

Start conditions for

flying MDI do not exist

-Control signal "reset technology" [RST]

activated

-Control signal "follow-up mode" [FUM]

activated

Effect:

The "MDI on-the-fly" function is not executed.

Ensure that the control signals are activated

correctly.

Loading...

Loading...