S5-95U, SINEC L2 Data Transfer with PLC-to-PLC Connections

6 Data Transmission Using PLC-to-PLC

Connections

This chapter provides you with the following information:

• How this type of data transmission functions in principle

• How to communicate with the CP 5430 communications processor

• How to set parameters for the programmable controllers

• How to program with STEP 5 for this type of data transmission (examples)

6.1 Features of the PLC-to-PLC Connections

• You use PLC-to-PLC connections to connect active stations.

• You can set parameters in DB1 for a maximum of 31 PLC-to-PLC connections.

• You use the integral function blocks L2-SEND and L2-RECEIVE to communicate via PLC-to-PLC

connection. L2-SEND and L2-RECEIVE are described in detail in chapter 5.

• For L2-SEND you need to specify the following parameters:

- The destination programmable controller as the job number

The job number is identical to the destination station address on the SINEC L2 network.

- The data to transmit

• For L2-RECEIVE you need to specify the following parameter:

- The source programmable controller as the job number.

(The job number is identical to the source station address on the SINEC L2 network.)

• Please note that

- a specific status byte ‘Transmit’ STBS belongs to L2-SEND and each of the job numbers

- a specific status byte ‘Receive’ STBR belongs to L2-RECEIVE and each of the job numbers

• You can transmit or receive a maximum of 242 bytes of data per job.

• You can transmit in parallel to several stations.

• You can receive in parallel to several stations.

• You can transmit faster using PLC-to-PLC connections than using standard connections.

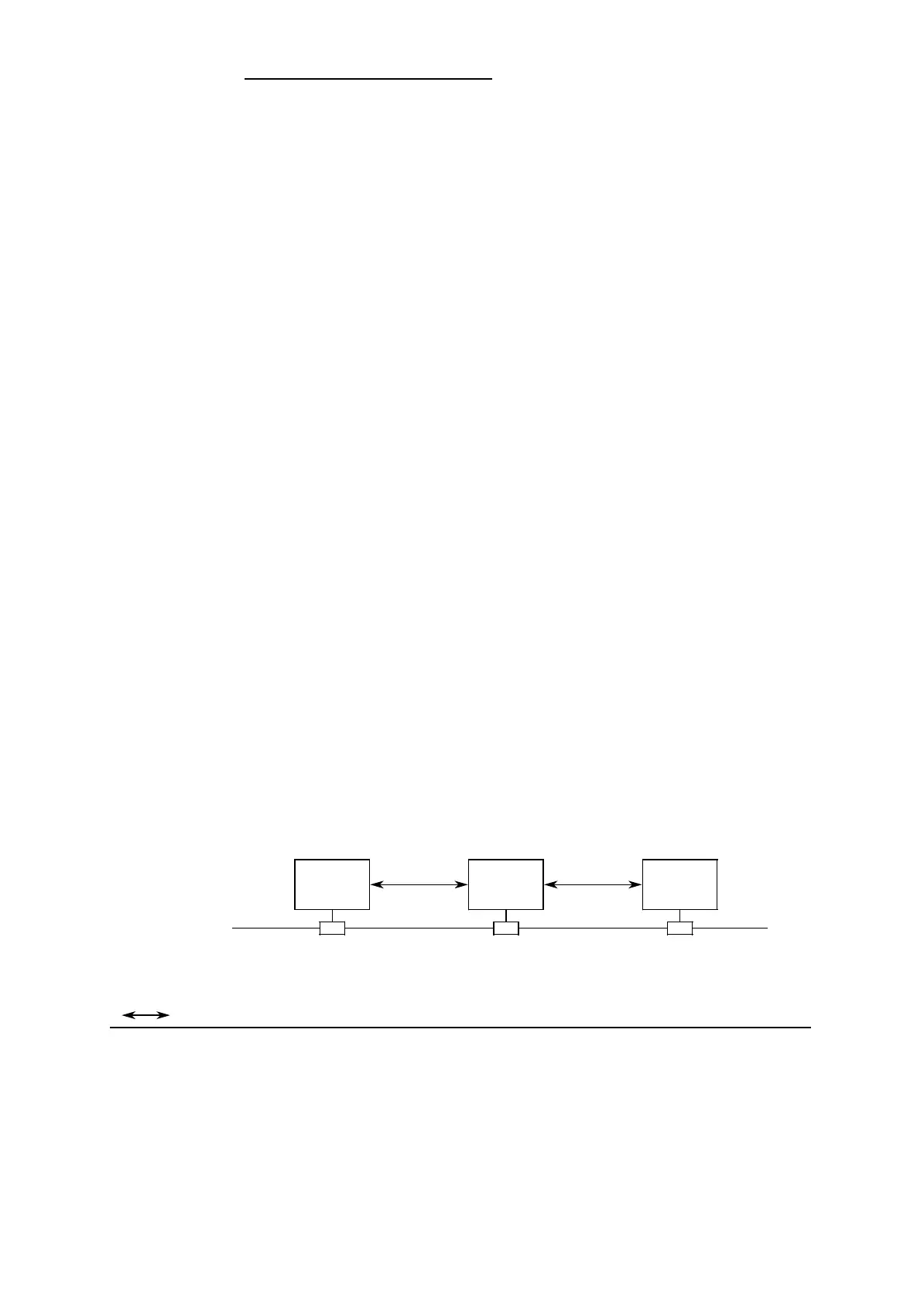

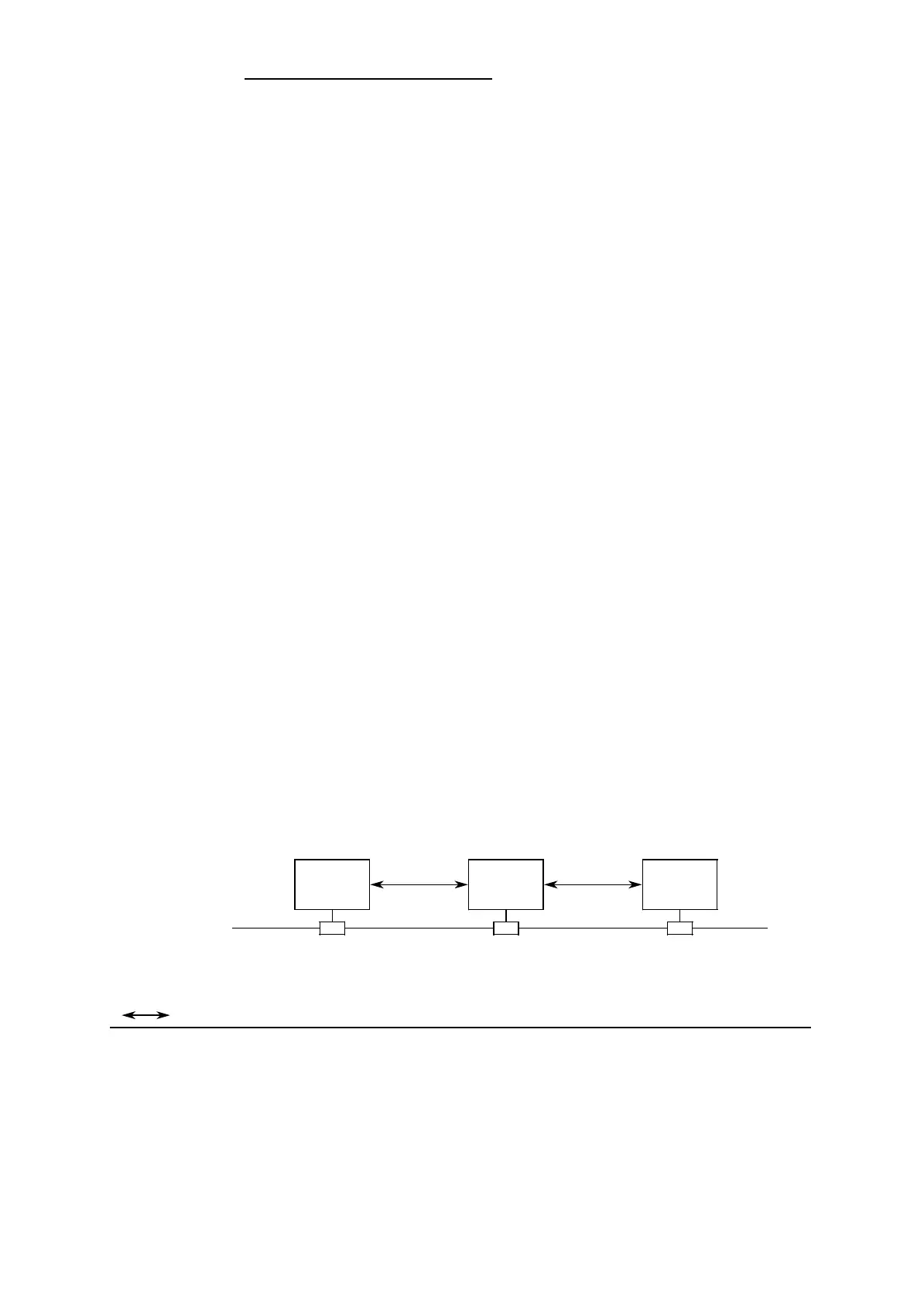

Figure 6-1 shows a possible hardware configuration ( section 1.5) for the PLC-to-PLC

connections. All examples in section 6.3 refer to PLC 1 and PLC 2 in this configuration.

Figure 6-1. Example: Hardware Configuration for PLC-to-PLC Connection

Bus

Passive

stations

PLC to PLC connection

Active

stations

CP 5430 S5-95U

(PLC 1)

S5-95U

(PLC 2)

. . .

PLC-PLCPLC-PLC

none

EWA 4NEB 812 6112-02

6-1

Loading...

Loading...