Data Transfer with PLC-to-PLC Connections S5-95U, SINEC L2

6.3 Programming Example for Data Transmission via PLC-to-PLC

Connections Using Standard Function Blocks

This section explains the structure of the control programs for two programmable controllers.

Example:

PLC 1 and PLC 2 are to exchange data with one another, i.e., they will transmit and receive. Refer

to section 6.1 for the description of the hardware configuration.

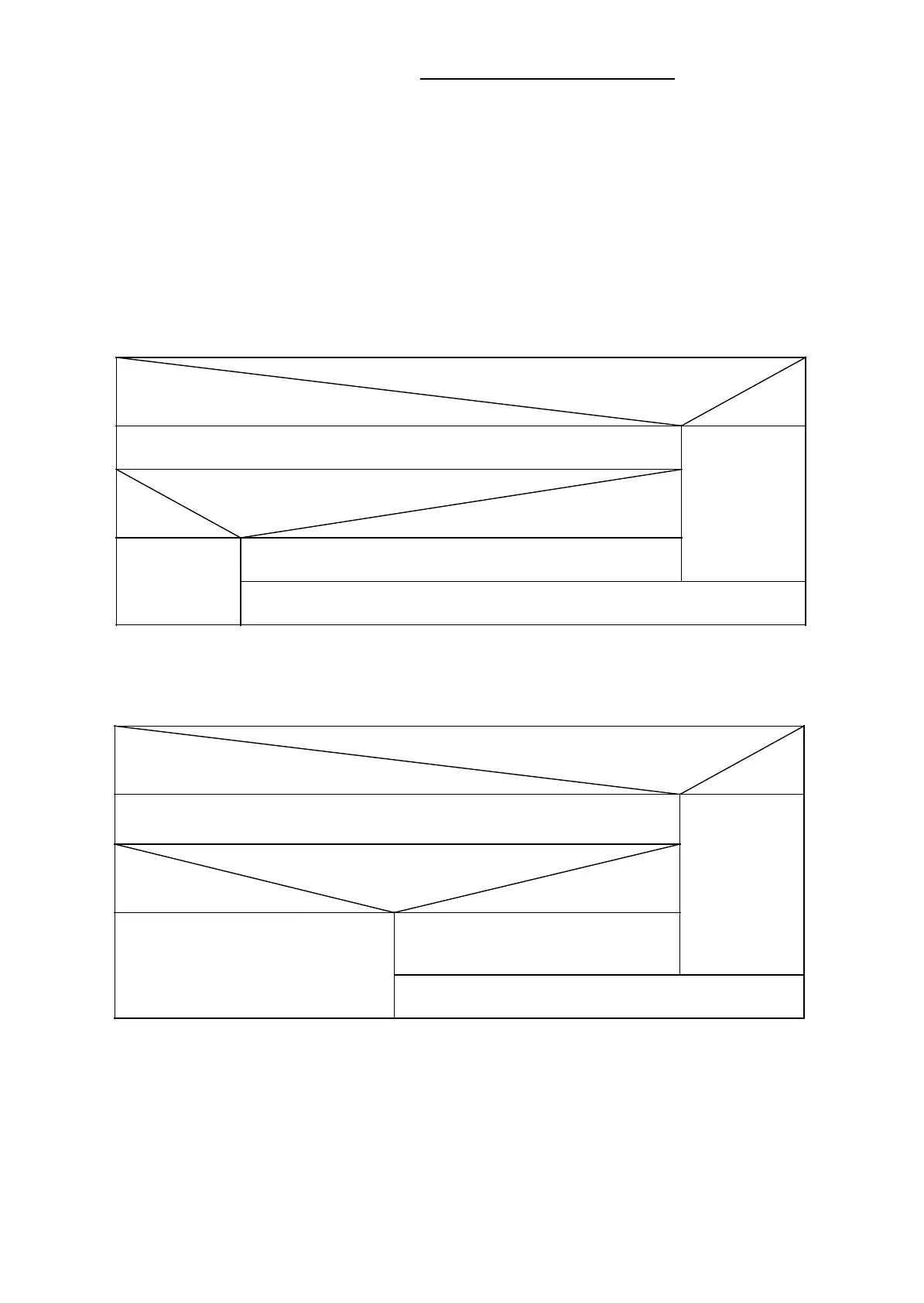

The control program in FB105 for transmitting data is structured as illustrated below.

Wish to transmit? (Transmit trigger bit set by the user?)

yes

no

Call up of function block L2-SEND

Has PAFE message or STBS error occurred?

yes no

Confirm transmit request. (The program resets the transmit trigger bit.)

Transmit request is

repeated automati-

cally (call up of L2-

SEND)

End

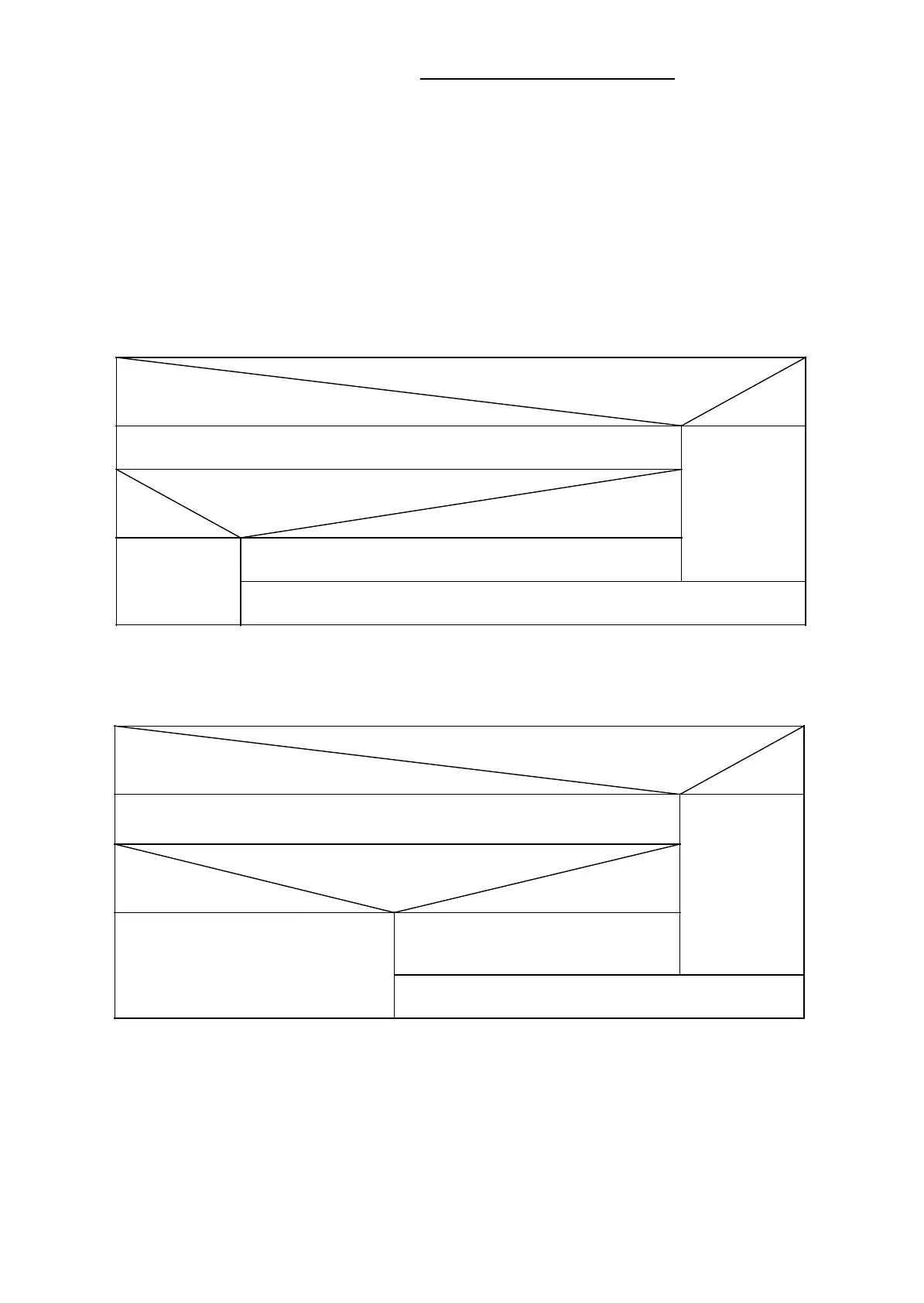

The control program in FB15 for receiving data is structured as illustrated below.

Receive enabled and “Receive viable”? (Receive enable bit set by the user

and bit 0 of STBR =1?)

yes no

Call up of function block L2-RECEIVE; data are fetched.

Receive request is repeated automatically

(call up of L2-RECEIVE)

Has PAFE message or STBR error occurred?

yes no

Confirm receive request. (The program resets the

receive enable bit.)

End

6-6

EWA 4NEB 812 6112-02

Loading...

Loading...