Programming and Operating — Turning Page 108 808D ADVANCED

ISO Mode

s

BASIC THEORY

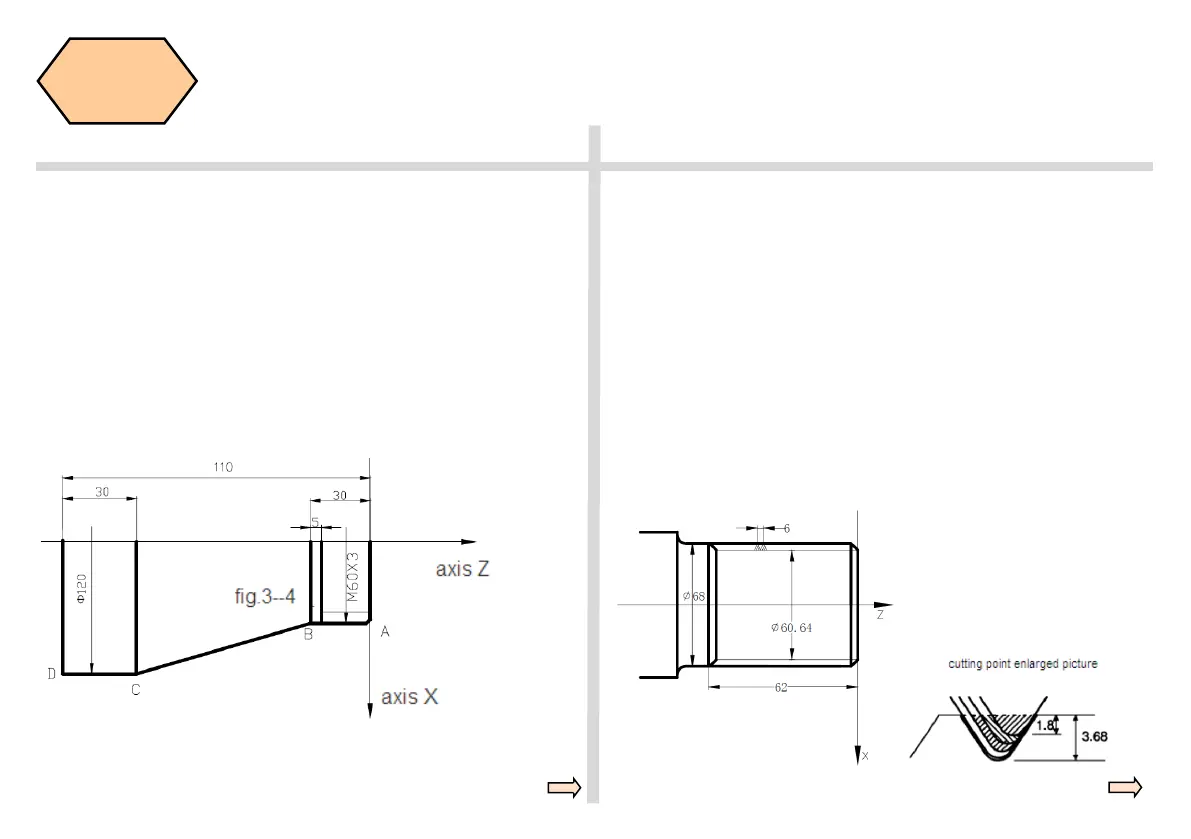

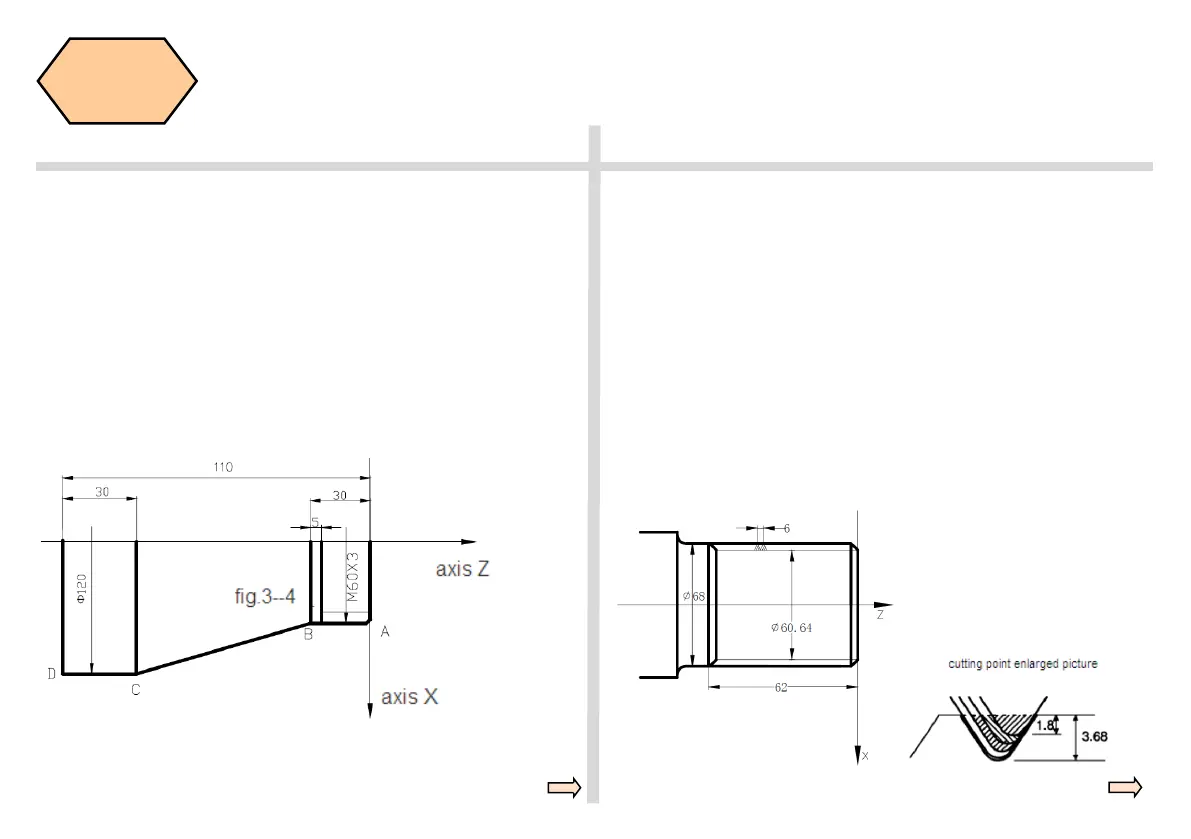

G76 thread cutting multi-cycles

Programming structures:

G76 P(m)(r)(a)—Q(Δd

min

)—R(d);

G76 X / U—Z / W—R(i)—P(k)—Q(Δd)—F(I);

Note:Please follow the specified structures

when programming!

G76 sample program:

O0013;

M3 S3000

G0 X80 Z5

G76 P020560 Q150 R0.1

; finishing repeat times 2, reverse

width 0.5 mm, tool angle 60º,

minimum cutting depth 0.15 mm,

finishing allowance 0.1 mm

G76 X60.64 Z-62 P3680 Q1800 F6

;thread teeth height 3.68 mm, first

thread cutting depth 1.8 mm,

thread lead 6 mm

G00 X100 Z50

M30

G92 Example

G92 sample program:

O0012;

M3 S1500

G0 X150 Z50 T0101; thread tool

G0 X65 Z5

G92 X58.7 Z-28 F3

;machining thread, divided into 4

cutting times, 1st cut : 1.3 mm

X57.7 ;2nd cut: 1 mm

X57 ;3rd cut: 0.7 mm

X56.9 ;4th cut: 0.1 mm

M30

G92 thread cutting cycle

Programming structures:

Straight thread cutting cycle in mm

G92 X / U—Z / W—F;

Straight thread cutting cycle in inches

G92 X / U—Z / W—I;

Cone thread cutting cycle in mm

G92 X / U—Z / W—R—F;

Cone thread cutting cycle in inches

G92 X / U—

Z / W—R—I;

Note:Please follow the specified structures when programming!

Loading...

Loading...