Programming and Operating — Turning Page 14 808D ADVANCED

Tool Setup

s

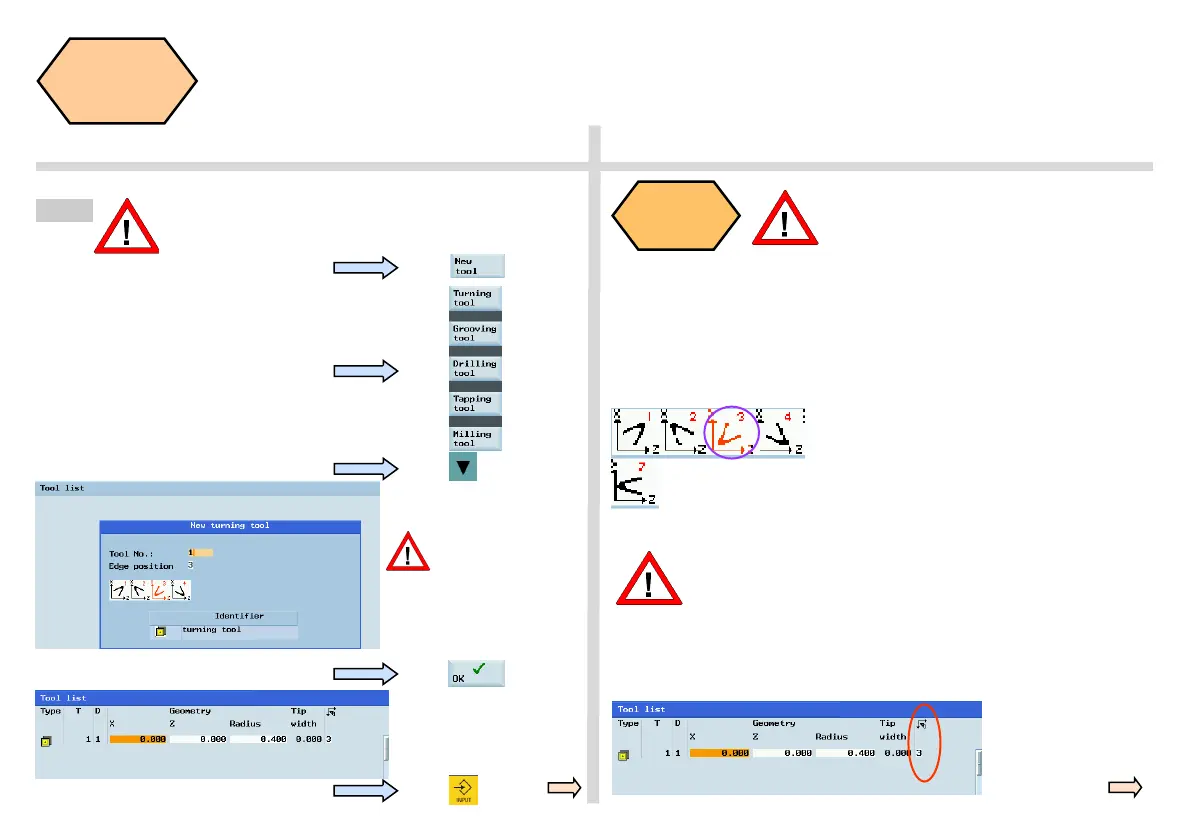

SEQUENCE

Press the “New tool” SK on the PPU.

Press the “OK” SK on the PPU

Press the “Input” button on the PPU

Enter “1” at “Tool No.”

Enter “3” at “Edge

position”.

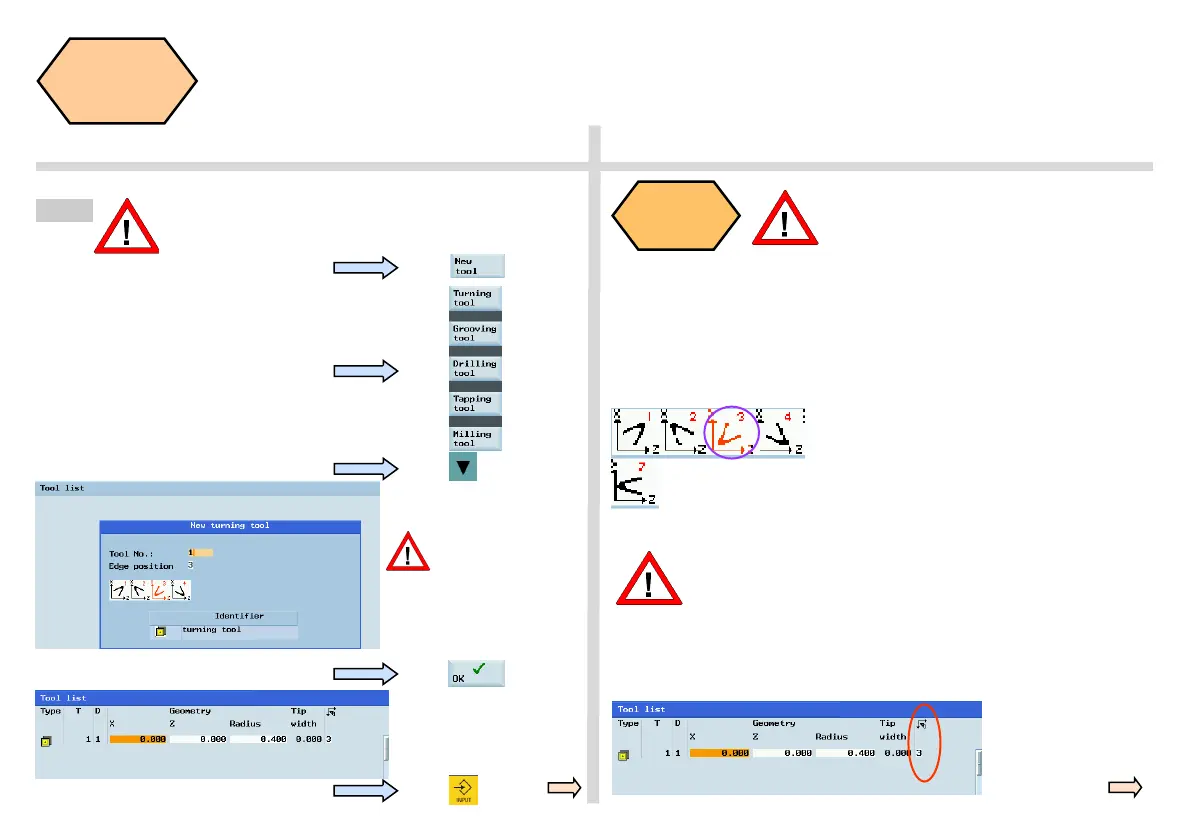

The correct “Edge

position” selection

directly determines the

correct tool compensation

which will be described in

the next unit.

Tool edge

position

code

Principle of correct tool edge position

code selection: Select the correspond-

ing tool edge position code according to

actual tool point direction!

Observe the relationship between the tool point direction and the positive

direction of the X axis and the Z axis.

Find the corresponding position relationship in the figure below and enter

the number in “Edge position”; the red coordinate in the purple circle is the

selected position code.

Note that the tool tip direction here is the direction after

the correct tool offset, not only the direction in tool load-

ing. And the correct of tool edge position code directly

affects the tool tip radius compensation!

The tool edge position code can also be changed in the

position showed in the figure.

Step 2

The range of tool numbers which can be created by

this system is 1 ~32000. The machine can be loaded

with a maximum of 64 tools / 128 tool edges.

Select the type of required tool.

Enter the “Radius” and/or

“Tip width” as required.

Note: Not every tool has eight position codes. All the options are shown above.

As to “turning tool” and “grooving tool”, 808D

ADVANCED provide 4 edges (#1~4) which are shown

on the left figure.

As to “drilling tool” and “tapping tool ”, 808D

ADVANCED provide only 1 edge (#7) which is also

shown on the left figure.

Loading...

Loading...