808D ADVANCED Page 31 Programming and Operating — Turning

Create Part

Program

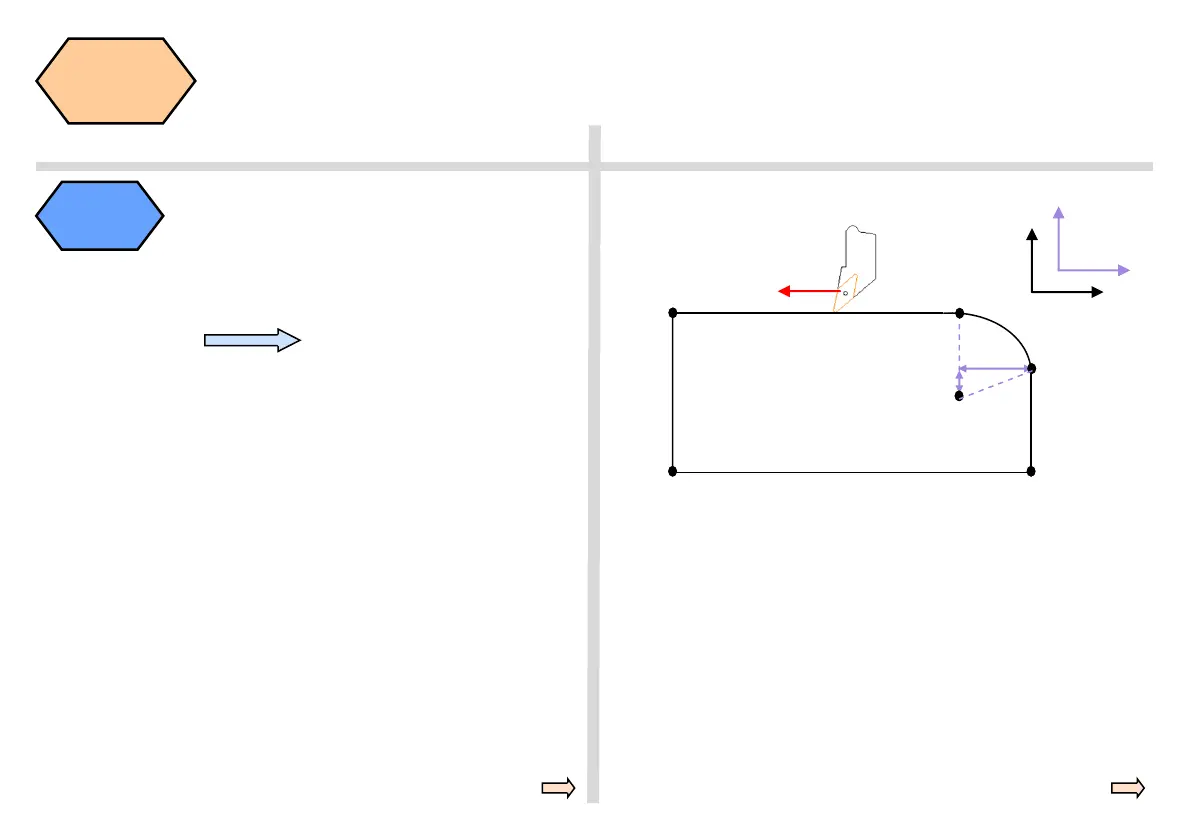

Part 1

s

(K)-35

SP

X50, Z0

X0, Z0

(I) -12

EP

SP = start point of circle

CP = center point of circle

EP = end point of circle

I = defined relative increment from start point to center point in X

K = defined relative increment from start point to center point in Z

Z-130

X75, Z-35

Z-130, X0

Z

X

CP

K

I

G2 = define circle direction in traversing direction = G2 clockwise

G3 = define circle direction in traversing direction = G3 counter-clockwise

Determine tool radius of T1 D1

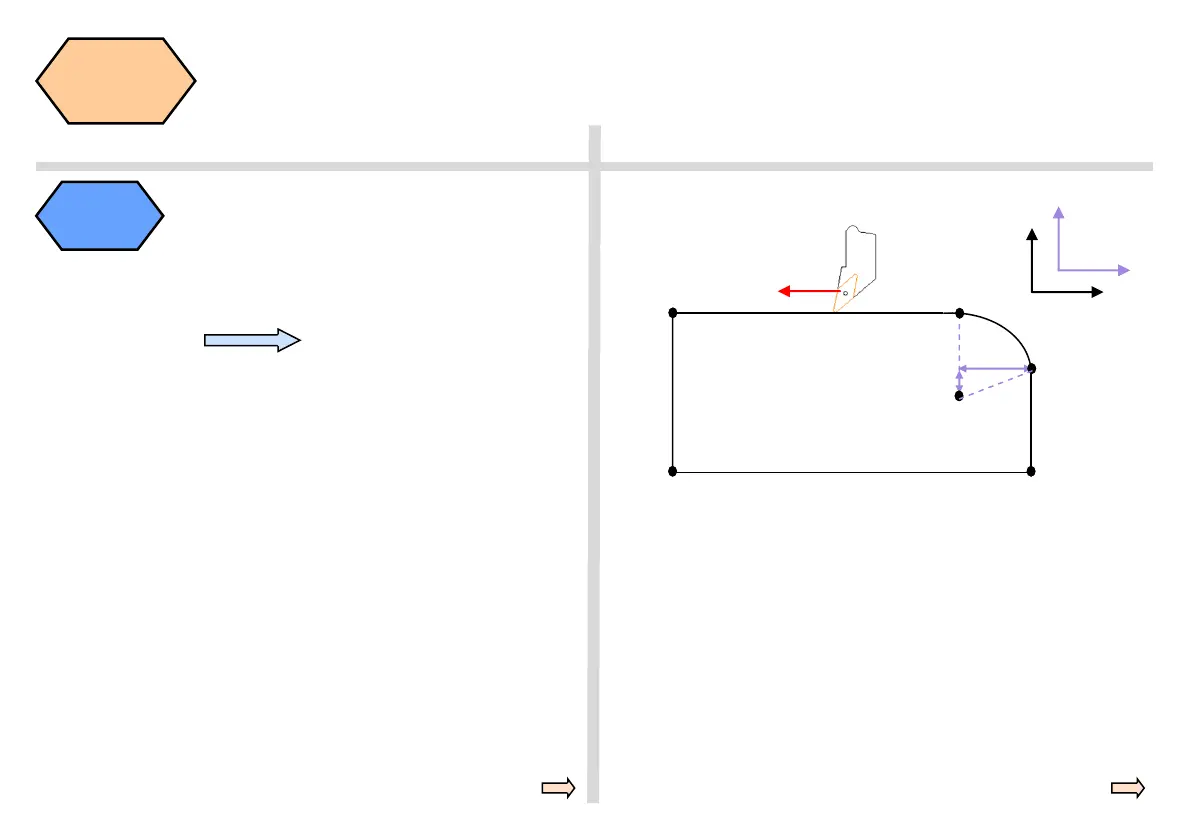

Turning

circles and

arcs

The circle radius

shown in the ex-

ample on the right

can be produced

with the specified

part program code.

When milling circles

and arcs, you must

define the circle

center point and the

distance between

the start point / end

point and the center

point on the relative

coordinate.

When working in the

XZ coordinate

system, the

interpolation

parameters I and K

are available.

N5 G17 G90 G500 G71

N10 T1 D1

N15 S5000 M3 G95 F0.3

N20 G00 X0 Z2

N25 G01 Z0

N30 G42 X50

N45 G03 X75 Z-35 I-12 K-35

N50 G01 Z-130

N60 G40 X120 Z-140

N35 G00 X300 Z500

Note:

N45 can also be written as follows

N45 G03 X75 Z-35 CR=37

Tool motion direction

BASIC THEORY

Two common types of defining circles

and arcs:

①:G02/G03 X_Z_I_k_;

②:G02/G03 X_Z_CR=_;

Arcs ≤180º,CR is a positive number

Arcs >180º,CR is a negative number

Loading...

Loading...