808D ADVANCED Page 97 Programming and Operating — Turning

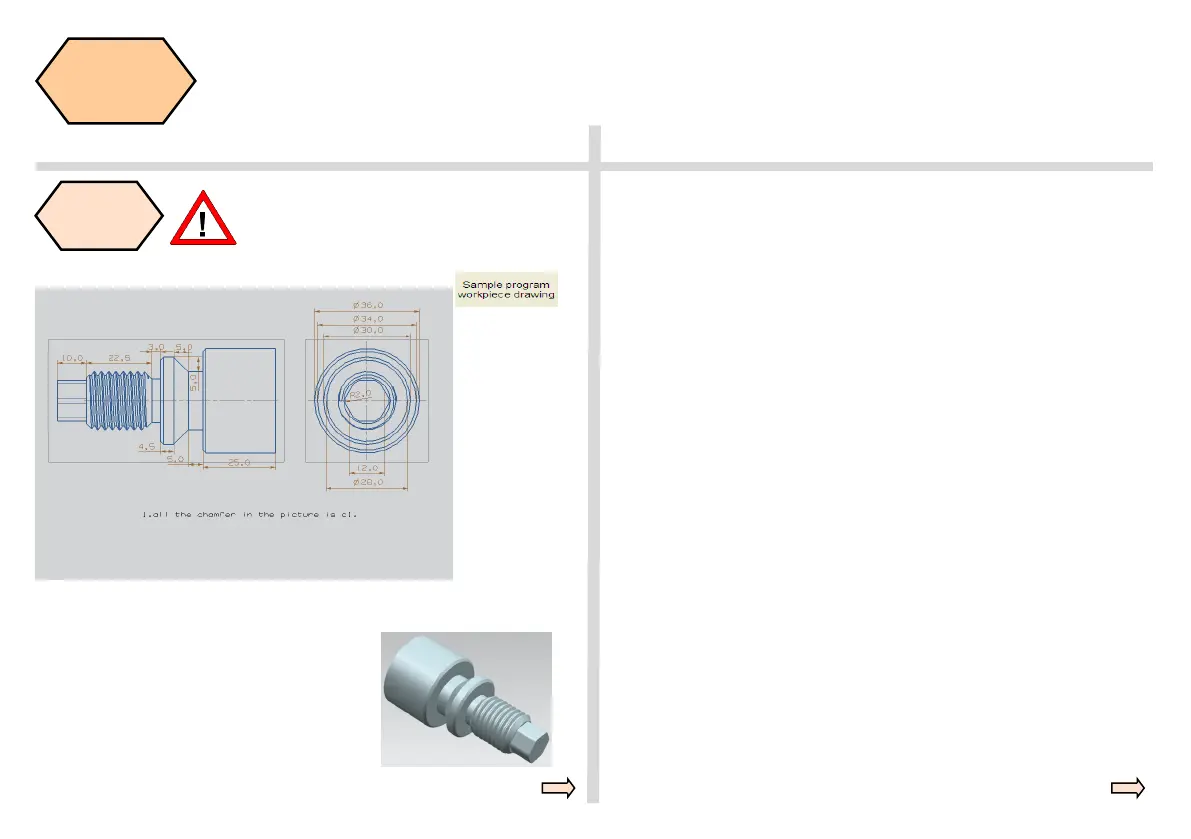

Sample

Programs

s

Machining Process

Actual effect

N10 G0X100Z200

N20 T1 D1

N30 M8

N40 M3S1000

N50 CYCLE95( "PART_SUB_4",

1.00000, , , 0.10000, 0.12000, 0.12000,

,1, , , )

N60 M3S1800

N70 CYCLE95( "PART_SUB_4",

1.00000, , , 0.10000, 0.12000, 0.12000,

0.05000, 5, , , )

N80 M3S1000

N90 CYCLE94( 20, -35.5, "E", 0)

N100 G0X100Z200

N110 M5

N120 T9D1

N130 M3S500

N140 CYCLE99( -10.00000, 20.00000,

-32.50000, 20.00000, 3.00000, 2.00000,

1.56300, 0.10000, ,0.00000, 7, 1,

2.50000, 300101, 1, ,0, 0, 0, 0, 0, 0, 0, 1,

, , ,0)

N150 G0X100Z200

N160 M5

N170 T3D1

N180 M3S600

N190 CYCLE93( 40.00000, -35.50000,

5.00000, 10.00000, ,45.00000, , ,-

1.00000, , ,0.100000, 0.100000,

2.00000, ,5 , )

N10

N20

N30

N40

N50 Rough cycle, cutting depth

1.5mm, finish allowance 0.1mm, rough

cutting feed rate 0.12mm/rev undercut

federate 0.12 cutting in the longitudinal

direction。

N60

N70 Finish cycle ,cutting depth

1.5mm, finish allowance 0.1mm, rough

cutting feed rate 0.12mm/rev undercut

feedrate 0.12 , finish feedrate 0.05

cutting in the longitudinal direction.

N80

N90 undercut “form E” with a starting

point X 20,Z-35.5)

N100

N110

N120

N130

N140 Thread cycle, pitch 2.5mm, start

point in Z-10 end point Z-35.5, parallel

thread with dia 20mm, Run in 3mm, run

out 2mm, thread depth 1.563mm, finish

allowance 0.1mm, number of rough cuts

7, non cutting passes 1, constant in-

feed .

N150

N160

N170

N180

N190 Groove, start point X40,Z-35.5,

width of groove 5mm, depth 10mm,

infeed depth 1mm, angle 1 45deg ,

finish allowance on sides 0.1mm,infeed

depth of cut 2mm,CHF chamfer type.

Tool information:

T1: rough/finish turn D0.2

T3: Thread

T9: Grooving 3 mm wide tip

T10: Milling cutter Φ=12

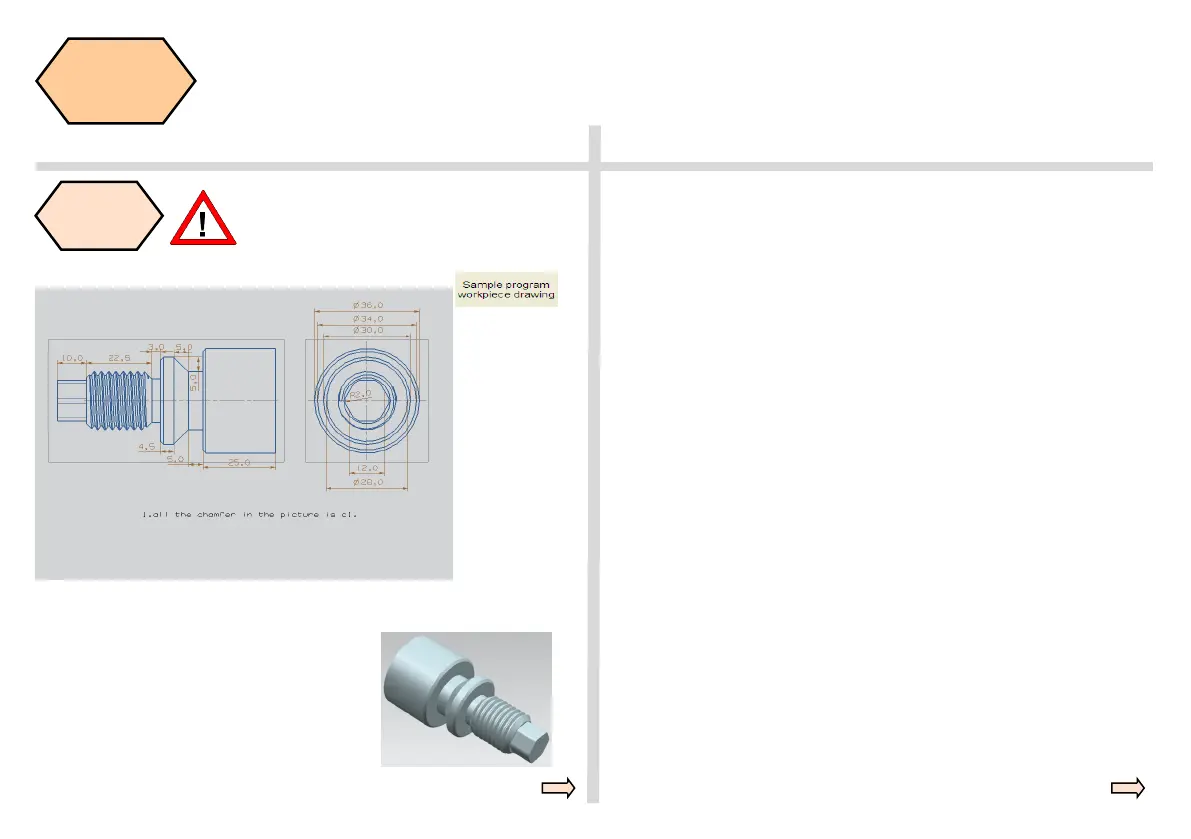

Turning

program 4

Make sure all the preparations and safety

measures have been performed before

machining!

Loading...

Loading...