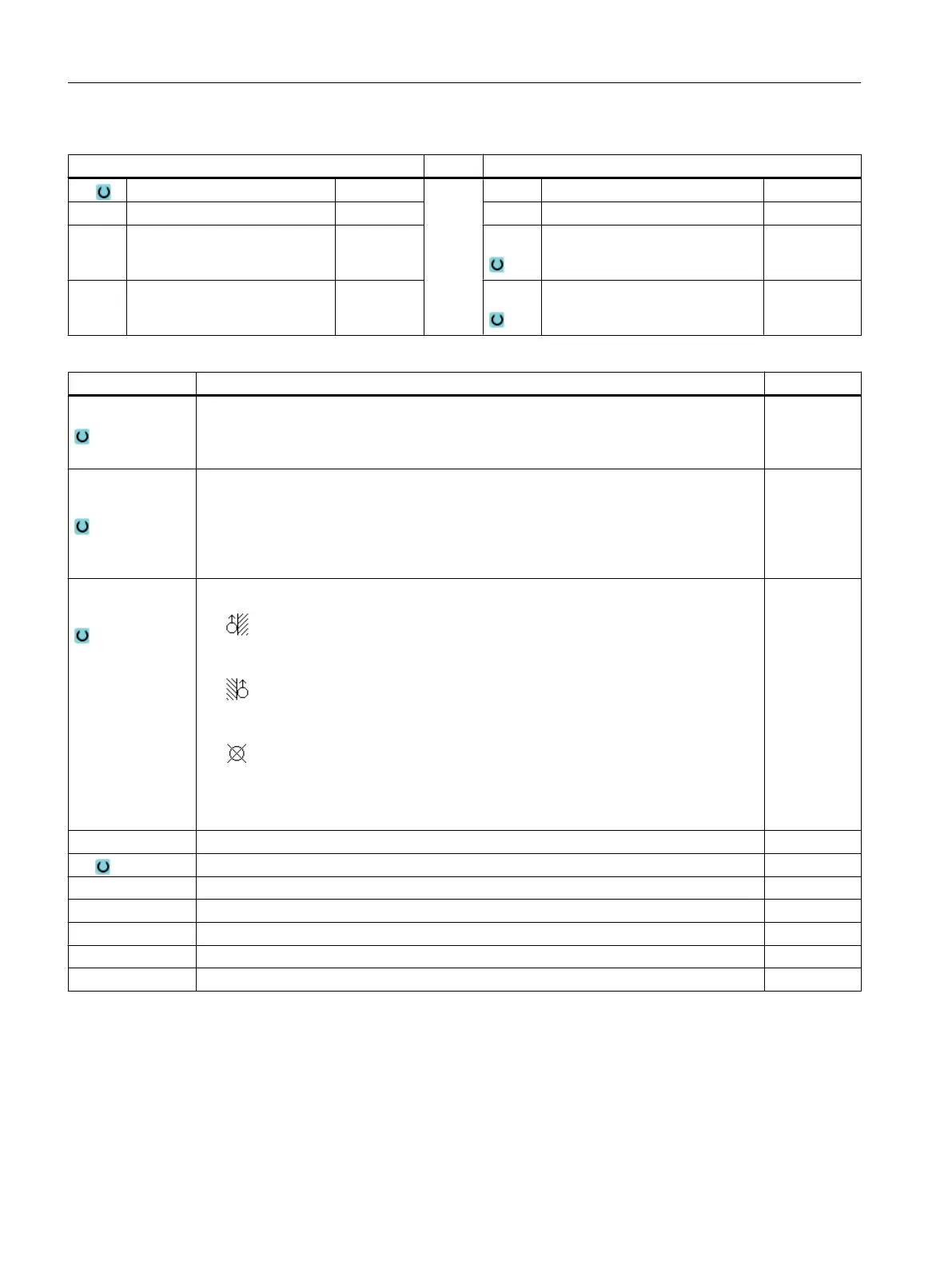

Parameters, G code program Parameters, ShopMill program

PL Machining plane T Tool name

RP Retraction plane mm D Cutting edge number

SC Safety clearance mm F Feedrate mm/min

mm/tooth

F Feedrate * S / V Spindle speed or constant cutting

rate

rpm

m/min

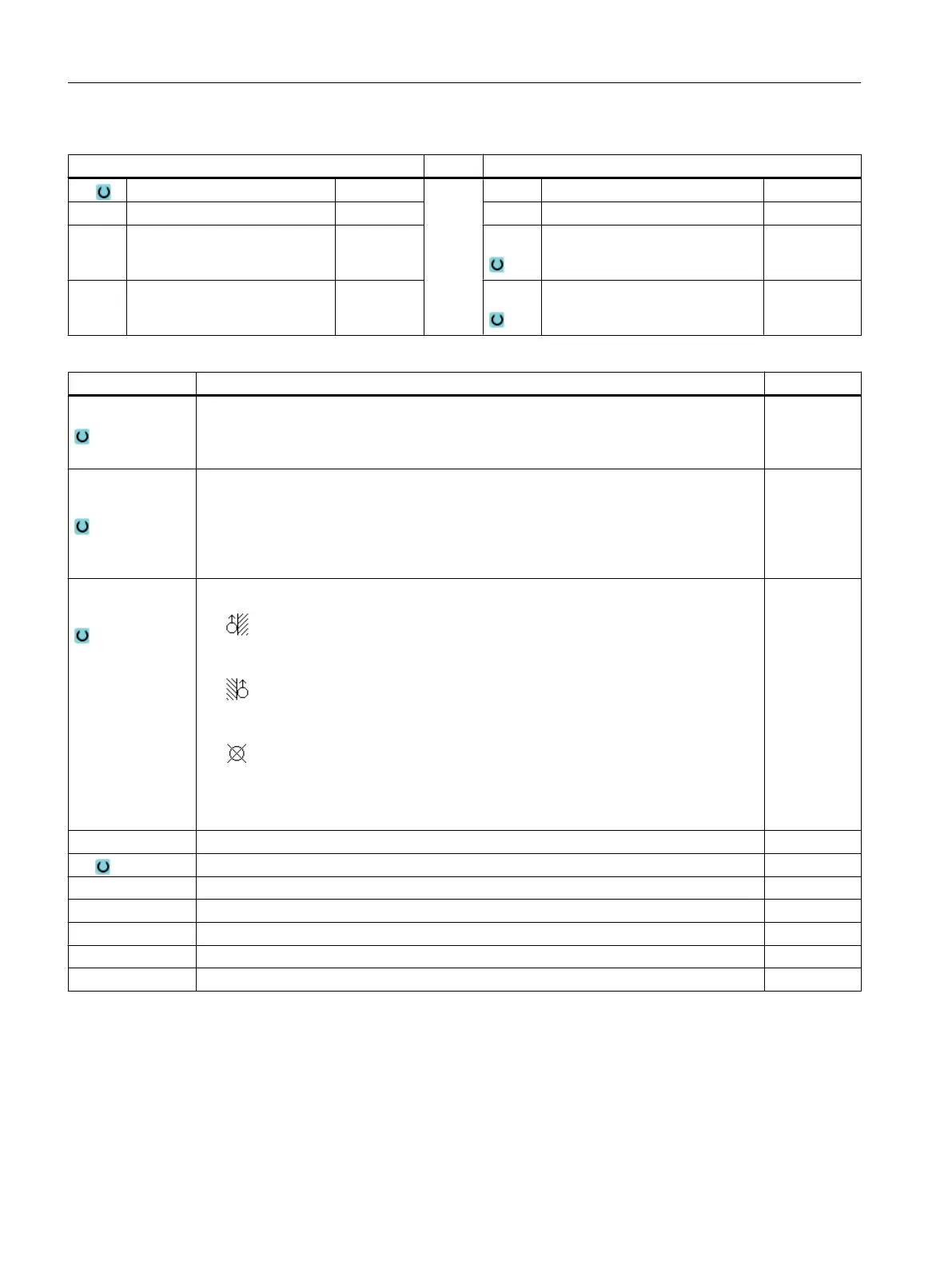

Parameter Description Unit

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

● Chamfering

Machining direc‐

tion

Machining in the programmed contour direction

● Forward:

Machining is performed in the programmed contour direction

● Backward:

Machining is performed in the opposite direction to the programmed contour

Radius compen‐

sation

● Left (machining to the left of the contour)

● Right (machining to the right of the contour)

● off

A programmed contour can also be machined on the center-point path. In this case,

approaching and retraction is only possible along a straight line or vertical. Vertical ap‐

proach/retraction can be used for closed contours, for example.

Z0 Reference point Z (abs or inc)

Z1 Final depth (abs) or final depth referred to Z0 (inc) - (only for ∇ and ∇∇∇) mm

DZ Maximum depth infeed - (only for ∇ and ∇∇∇) mm

UZ Depth finishing allowance - (only for ∇) mm

FS Chamfer width for chamfering (inc) - (for chamfering only) mm

ZFS Insertion depth of tool tip (abs or inc) - (for chamfering only) mm

UXY Finishing allowance, plane - (only for ∇ and G code, not for radius compensation off) mm

Programming technological functions (cycles)

10.3 Contour milling

Milling

494 Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

Loading...

Loading...