3.5 Connecting

When connecting, avoid bending cable lugs or cables, or the use of other forms of mechanical

force on the terminals. Otherwise, leakage could disable the safety device (overpressure

disconnector).

Provide sucient mechanical strain relief for the cable.

Ensure rm xing of terminals, xing torque to be applied as per individual specication.

In any case, the maximum specied terminal current may not be exceeded. Please refer to the

technical data of the specic series.

Parallel connection of capacitors via the terminal is not recommended.

3.5.1 Connecting the supply cable

Cable specication

The connection cable must be of exible type, material should preferably be copper.

Do not use solid core cables.

Attach the supply cable only with the maximum permissible torque values.

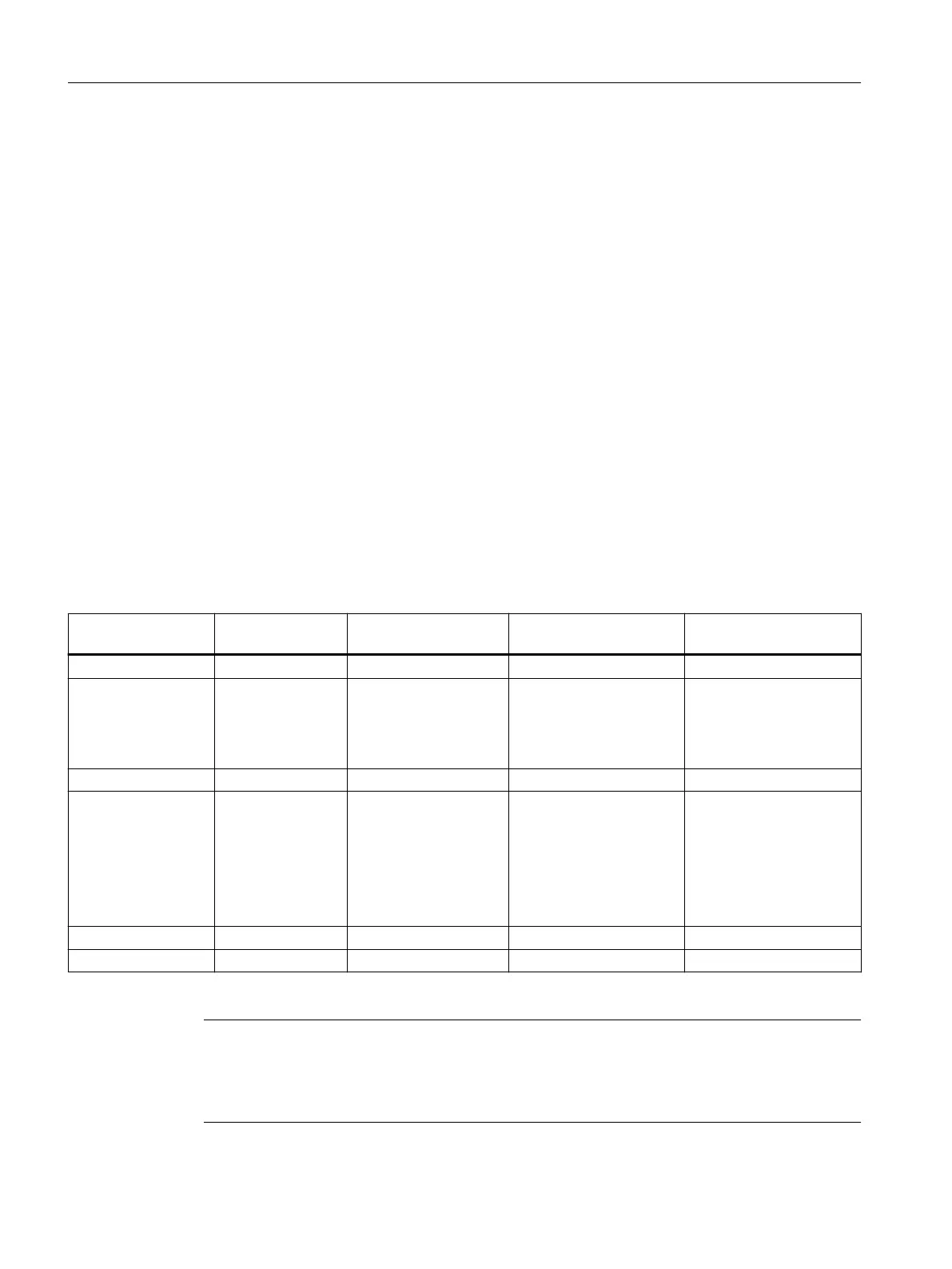

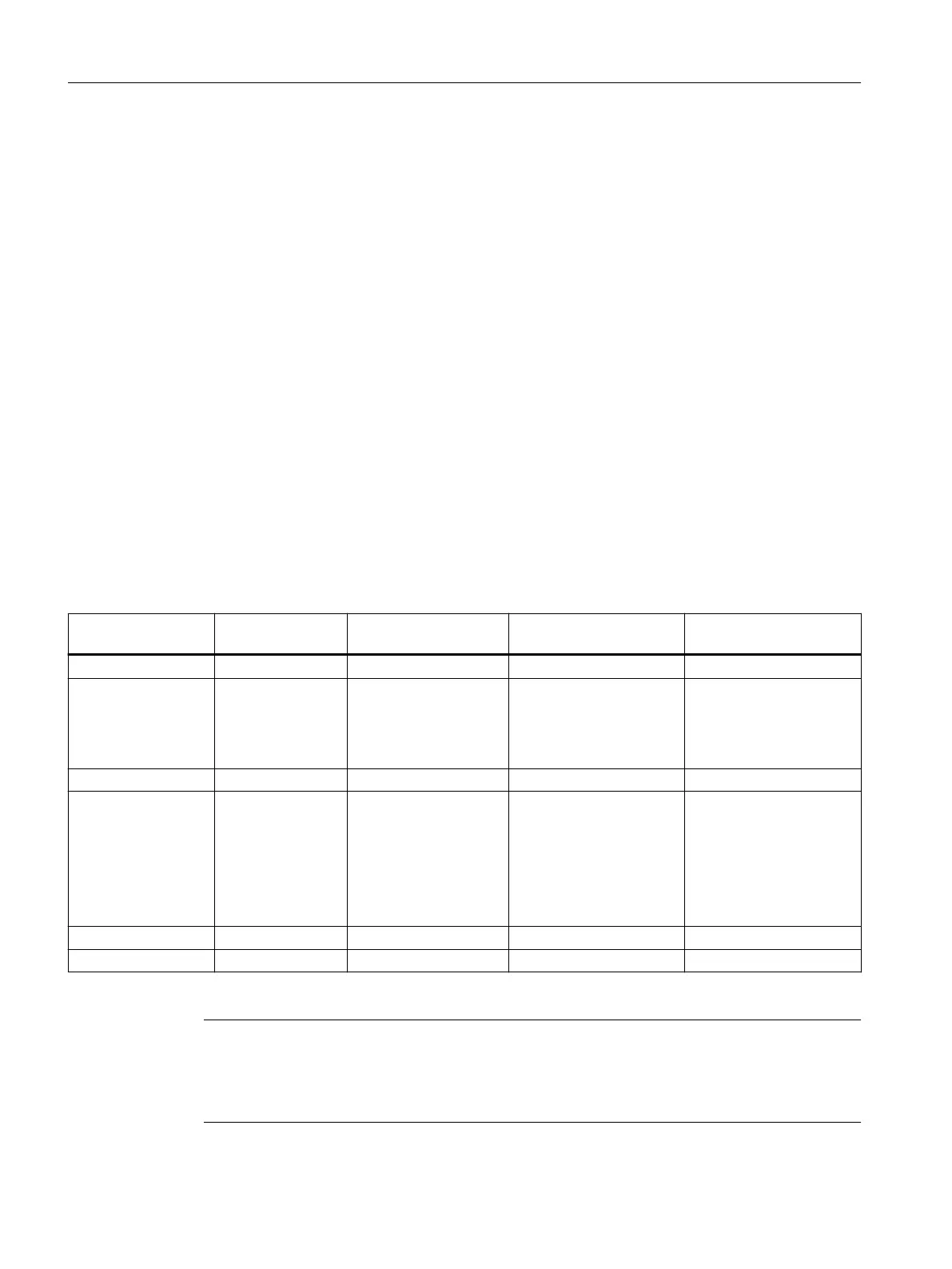

Product type Screws Maximum cable cross

section

Maximum allowable

RMS total current

Maximum permissible

torque values

PhaseCap Premium M5 25 mm

2

80 A 2,0 Nm

PhaseCap Compact:

Terminal Type A

Terminal Type B

Terminal Type C

M4

M5

M5

16 mm

2

25 mm

2

25 mm

2

50 A

80 A

80 A

1,2 Nm

2,0 Nm

2,0 Nm

DeltaCap M5 25 mm

2

55 A 2,0 Nm

PhaseCap Energy+:

Terminal type A

Terminal type B

Terminal type C

Terminal type D, E

Terminal type F

M4

M5

M4

M5

M6

16 mm

2

25 mm

2

16 mm

2

25 mm

2

35 mm

2

50 A

80 A

50 A

50 A

130 A

1,2 Nm

2,0 Nm

1,2 Nm

2,0 Nm

2,5 Nm

PhaseCap HD M6 35 mm

2

130 A 2,5 Nm

PhiCap M4 16 mm

2

50 A 1,2 Nm

Further information can be found in the Appendix.

Note

Prevent heating the cables.

The connection cables to the capacitor should be dimensioned for a current of at least 1.5 times

the rated current so that no heat is conducted into the capacitor.

Mounting

3.5 Connecting

Installation and maintenance instructions for Power Factor Correction (PFC) capacitors

16 Installation Manual, 05/2022, L1V30884033A

Loading...

Loading...