A5E32725813 XPS 10/15 F Series Transducer Page 13

Applications

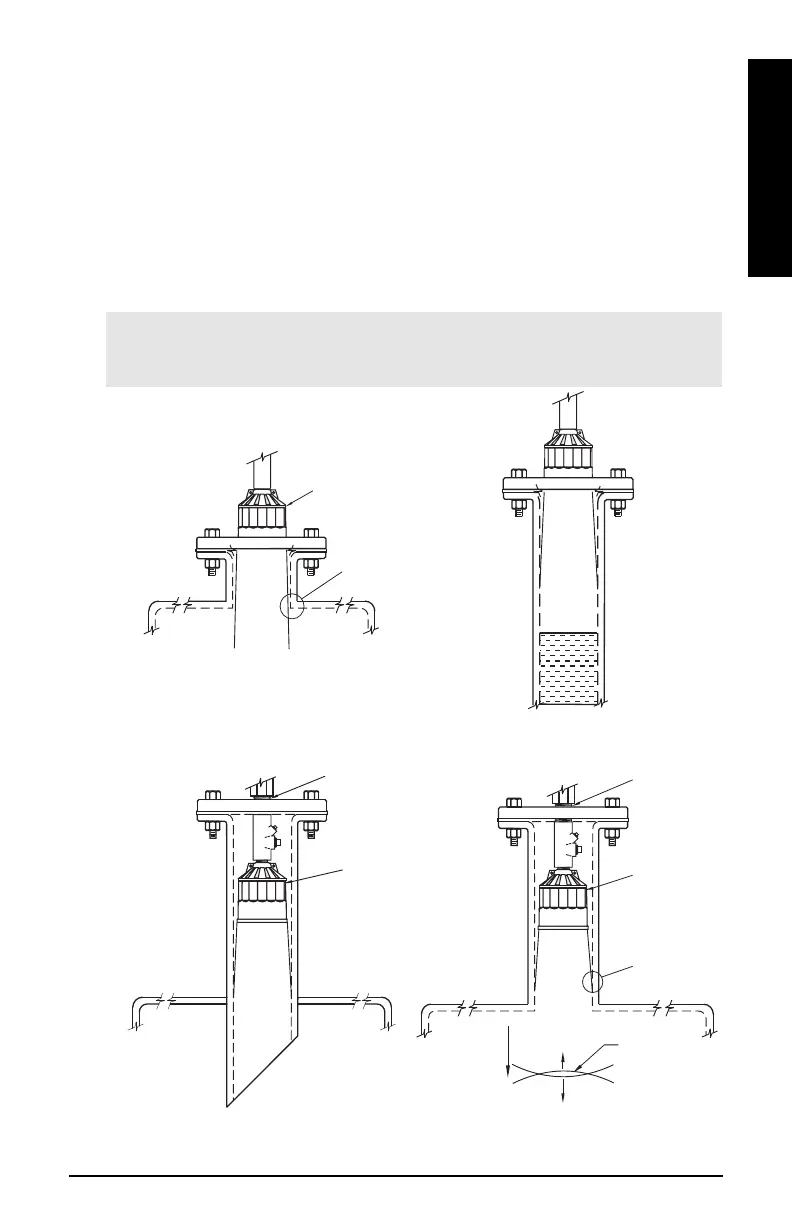

Standpipes

In many applications, access must be made via a standpipe. In such cases,

Siemens can provide factory bonded flanged transducers or a split flange kit

that will readily mate to the flanged standpipe. Another option is to hang the

transducer from a blind flange.

The standpipe length should be as short and the diameter as large as

possible. As a rule of thumb, the -3 dB cone of the sound beam should not

intersect the standpipe wall in applications opening into a vessel or larger

area. Otherwise, additional blanking will be required to compensate for the

interference zone created by the opening.

Note: When using a stilling well, make sure there is no build-up, welds,

couplings, or other debris on the inside of the well wall. This can affect

reliability of measurement.

no additional blankin

re

uired no additional blankin

re

uired

no additional blanking required near blanking extension of 150 mm (6”)

past end of standpipe may be required.

no

intersection

flanged

transducer

vessel

no

vessel

nipple

welded into

blind flange

transducer

sound beam

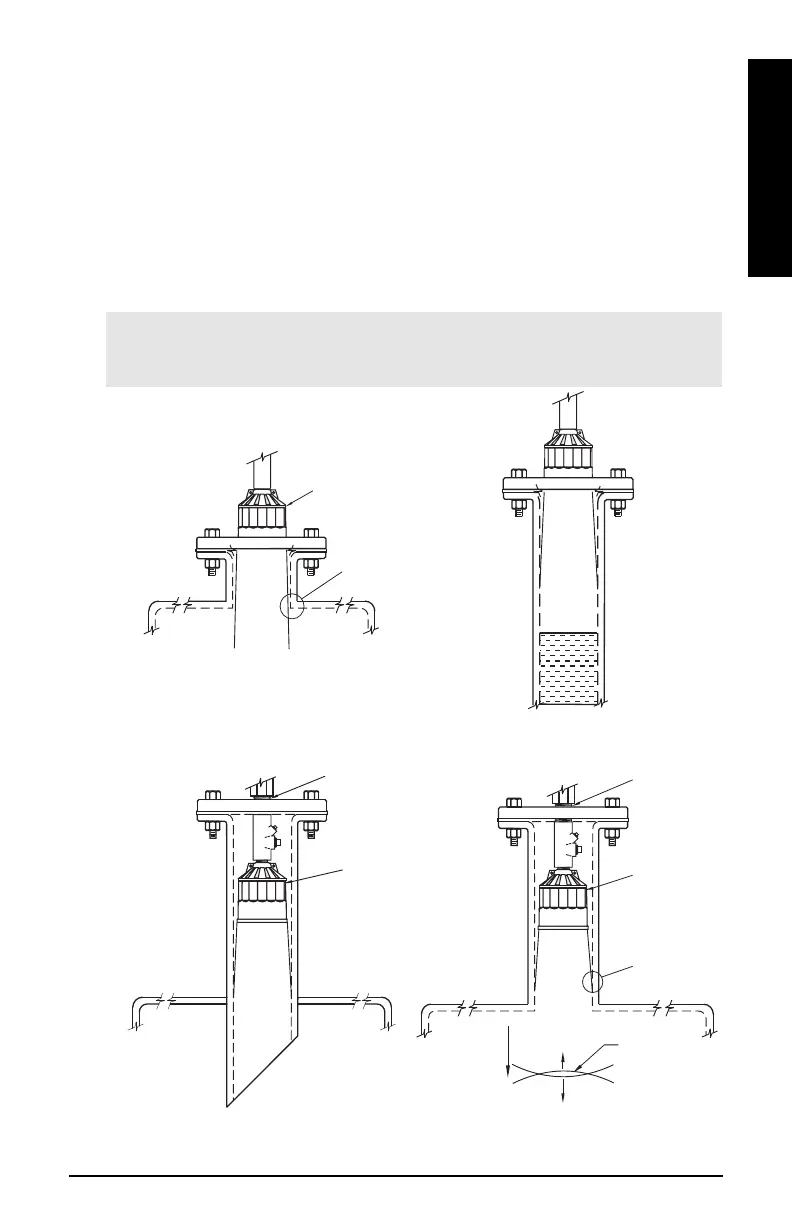

intersects

reflection at

interference

zone created

by opening

vessel

standpipe

end cut on a

45° angle

typically

transducer

nipple

welded into

blind flange

transducer

can read

level inside

or below

standpipe

Loading...

Loading...