4

General Safety Instructions 2

Introduction 4

Disconnect and Lock-out Procedures 4

Specifications 5

Installation and Major Components 6

Priciples of Operation 7

Maintenance and Lubrication 9

Electric:

! Sequence, MCD (Std.) 10

! Diagram, MCD (Std.) 11

! Sequence, MCD (w/ Oper. Int.) 12

! Diagram, MCD (w/ Oper. Int.) 13

! Control Panel 14

Machine:

! Parts List, Removal & Replacement 16

! Micro Switch Adjustment 24

! Covers & Signs 28

! Recommended Spare Parts 30

! Troubleshooting 31

Modular Chute:

! General Information 35

! Parts List 38

! Optional Chute Support 43

! Troubleshooting 44

Dispenser:

! Loading and Threading 46

! Adjustments 47

! Parts List 48

! Conversion 50

Machine Options 51

INTRODUCTION

The placement of the welding head on the

side of the MCD makes possible a lower

conveyor height, an easier fit into an existing

conveyor system, handier servicing, and

locates the weld where it is more convenient

to pull open. The MCD automatically makes a

strong weld in Contrax® or Tenax® co-

polymer strapping, joining the ends without

seals, adhesives, or solvents, and without

applied heat or electricity. The process

utilizes Tension-Weld®, is clean - no smoke

or odor, no grit to cause wear, no heaters to

carbonize. Tension-Weld is a development so

unique that the process, machine and weld

have been patented.

DISCONNECT AND LOCK-OUT

PROCEDURES

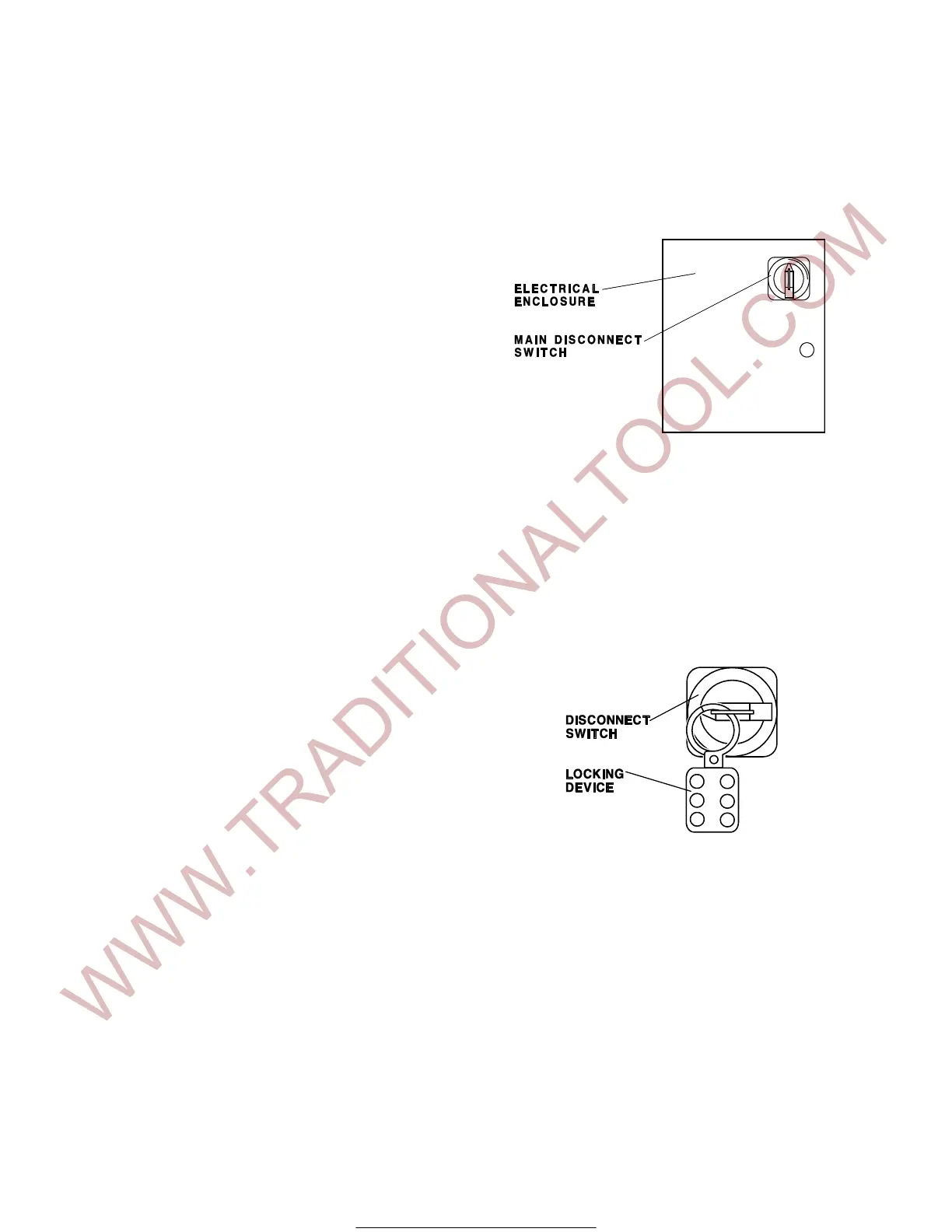

DISCONNECT SWITCH

The main disconnect switch is located on the

front of the electrical enclosure.

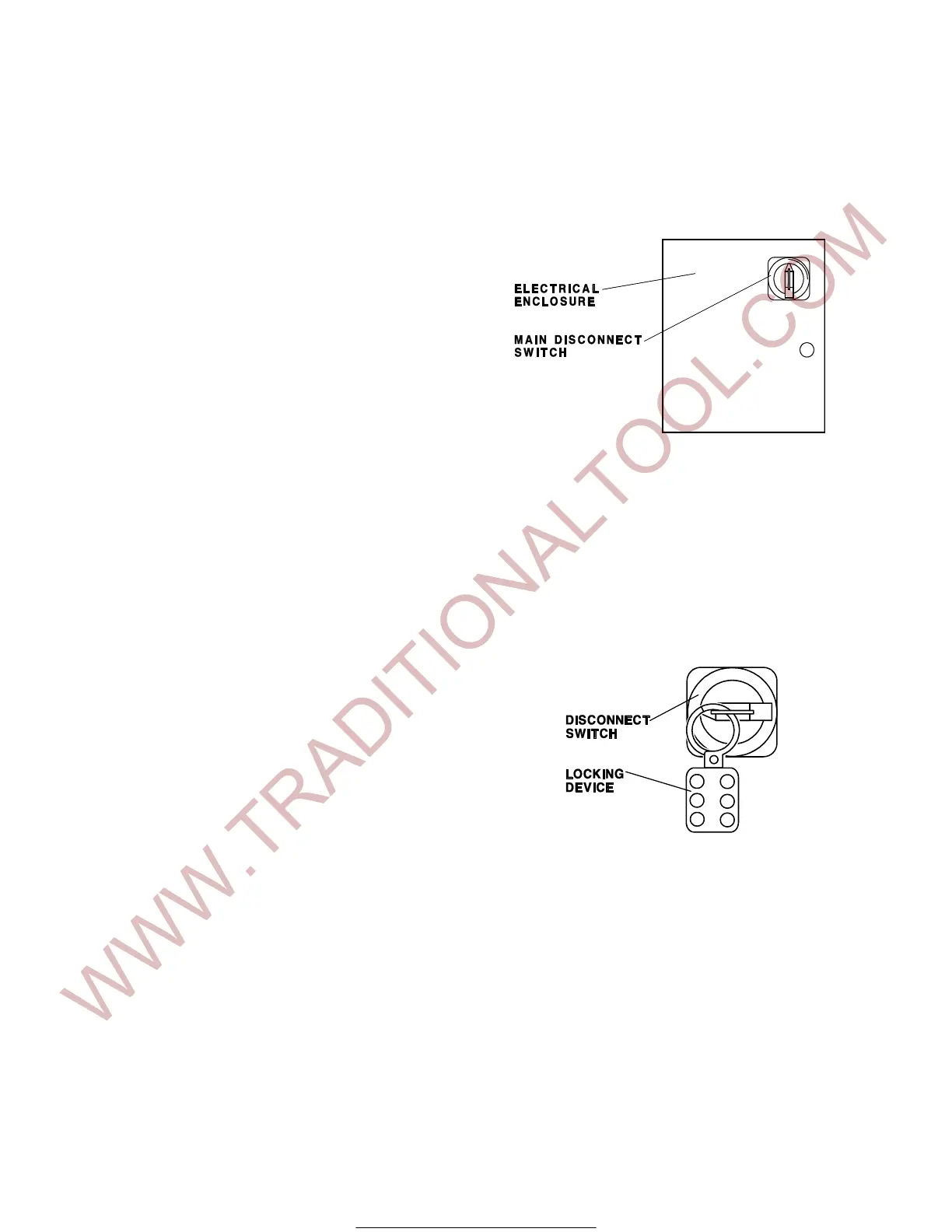

To disconnect/lock-out electrical power to

the machine, proceed as follows:

P Switch the main disconnect switch to the

OFF position.

P Locate an appropriate locking hole on the

switch, more than one may be provided,

and apply a locking device.

P Confirm that power has been

disconnected by pulling out machine start

button (return button to stop position).

For Parts & Service 1-877-862-6699

Loading...

Loading...