Page 8 / 26

3

Commissioning

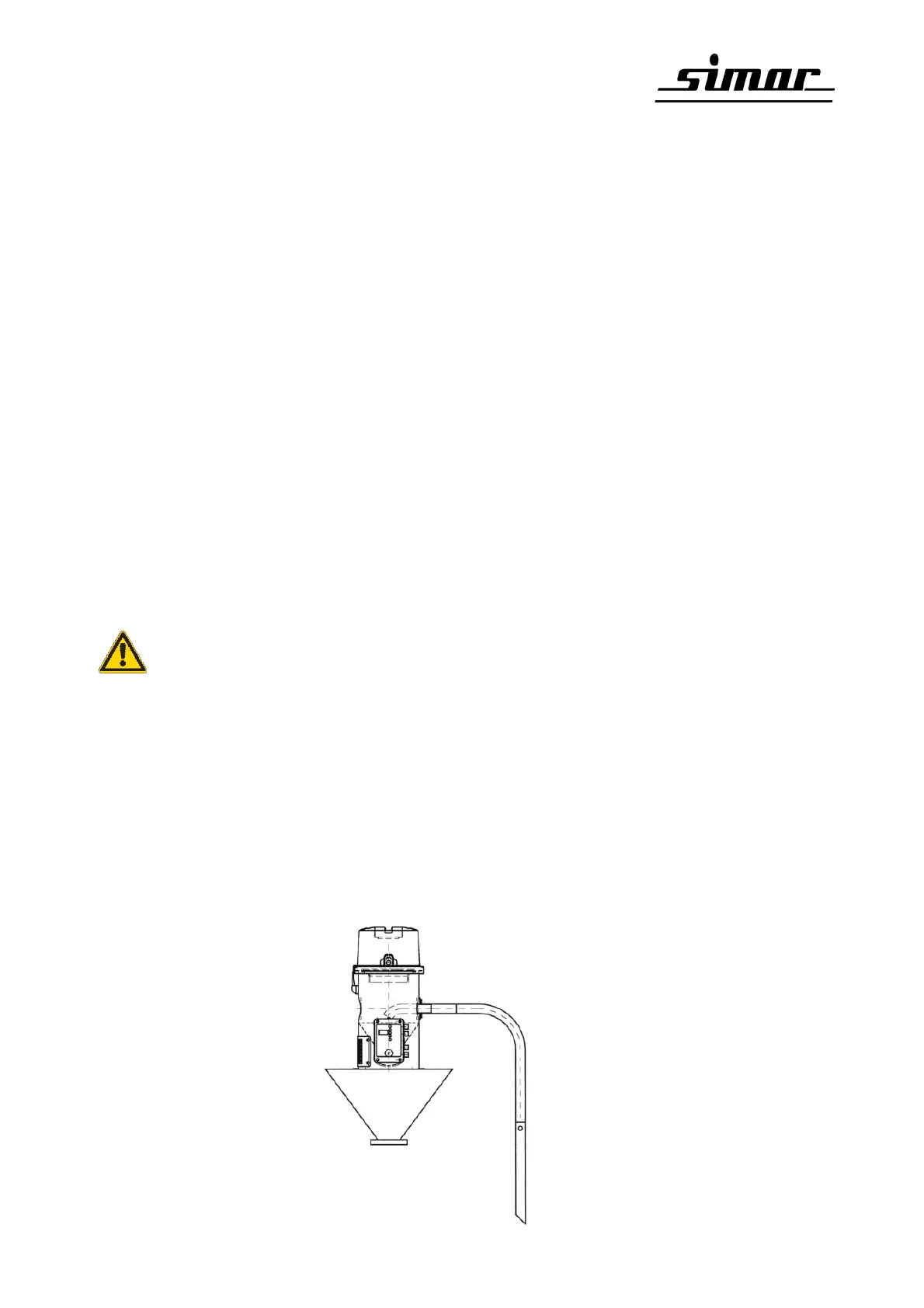

1. After unpacking check the separator for transportation damage.

2. Prepare the cover of the machine hopper:

Mount opening Ø202mm respectively Ø242mm and drill 4 holes for

screws M6 according to dimension sheet (sheet 19 and 20).

Alternately assembling with clamping ring.

3. Check the inside of the separator for residues of packing.

Remove adhesive tape from flap.

4. Mount the separator on lid of machine hopper,

mount seal between lid and separator (included in scope of delivery).

5. Mount feeding hose and suction pipe and connect to earth.

6. Connect air hose DN13 for filter cleaning,

do not use smaller diameter because of insufficient filter cleaning.

7. Max. 2,5bar !

8. Install fan, connect separator to fan; the unit is ready for operation now.

The following is to be observed:

1. Use Cekon plug for connection. Slow blowing fuse 10A.

2. All pipe joints and hose couplings to be leak proof.

3. Arrange piping vertically or horizontally; not inclined, if possible.

Never use bends with radius less than 500 mm.

4. Do not push the suction pipe into the material hopper; it will be pulled in

automatically during the first conveying processes.

5. Prevent filling through air inlet openings.

Loading...

Loading...