36

m

CAUTION

The adjustment of the Maximum Heating Tempera-

ture is managed by

"PAR 14"

(see paragraph "List of

parameters").

6.13.2 External timers and Room Thermostats

The heat demand can be by a "clean contact" conforming to

EN607301 connected to TA (see section

"Wiring diagram"

) or

by use of a dedicated Sime Remote Control (Home or Home

Plus). The boiler will automatically detect when a dedicated

control is connected.

6.13.3 EXAMPLE of use of the command/control

device on some types of heating systems

KEY

M System flow

R System return

Mb Hot water tank delivery

Rb Hot water tank return

CR Remote control

EXP Expansion card

SE External temperature sensor

SBL Hot water tank sensor (SB)

TA Room thermostat for boiler activation

TZ1÷TZ3 Room thermostat for the zone

VZ1-VZ3 Zone valves

RL1-RL3 Zone relays

P1-P3 Zone pump

SP Hydraulic separator

IP Floor system

VM Thermostatic mixer valve

TSB Low temperature safety thermostat

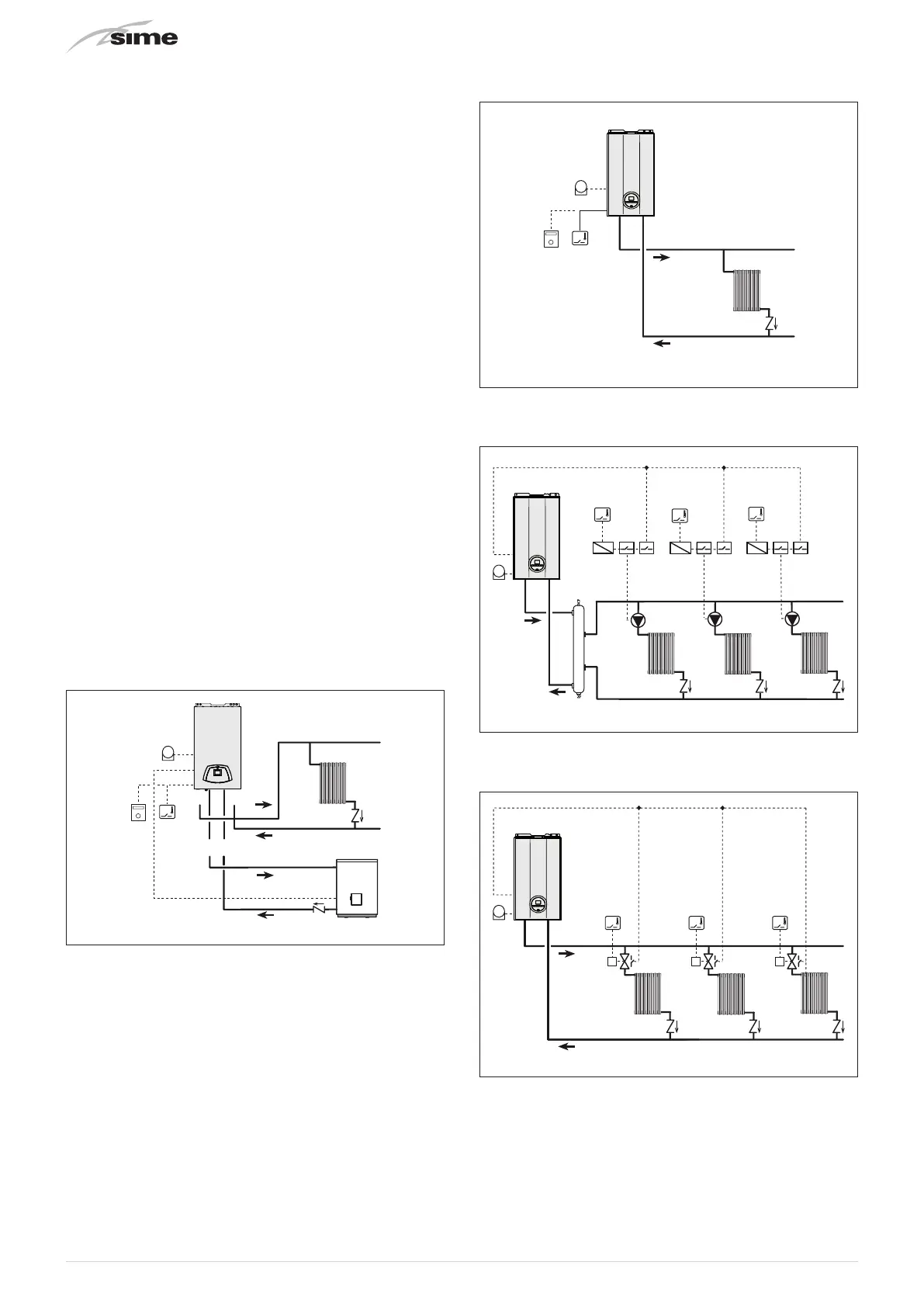

ONE DIRECT ZONE system and REMOTE HOT WATER TANK,

external sensor and room thermostat or, alternatively, re-

mote control.

R

M

Mb Rb

SE

TA

SBL

Fig. 38

m

CAUTION

The boiler is pre-arranged for connection to a re-

mote hot water tank. To use the boiler for HEATING

ONLY:

– disconnect the hot water tank sensor (SBL)

– set "PAR 02 = HYDRAULIC CONFIGURATION" to 1.

This operation must only be carried out by Profes-

sionally Qualified Personnel during the boiler com-

missioning phase.

ONE DIRECT ZONE system, external sensor and room ther-

mostat.

R

M

SE

TA

Fig. 39

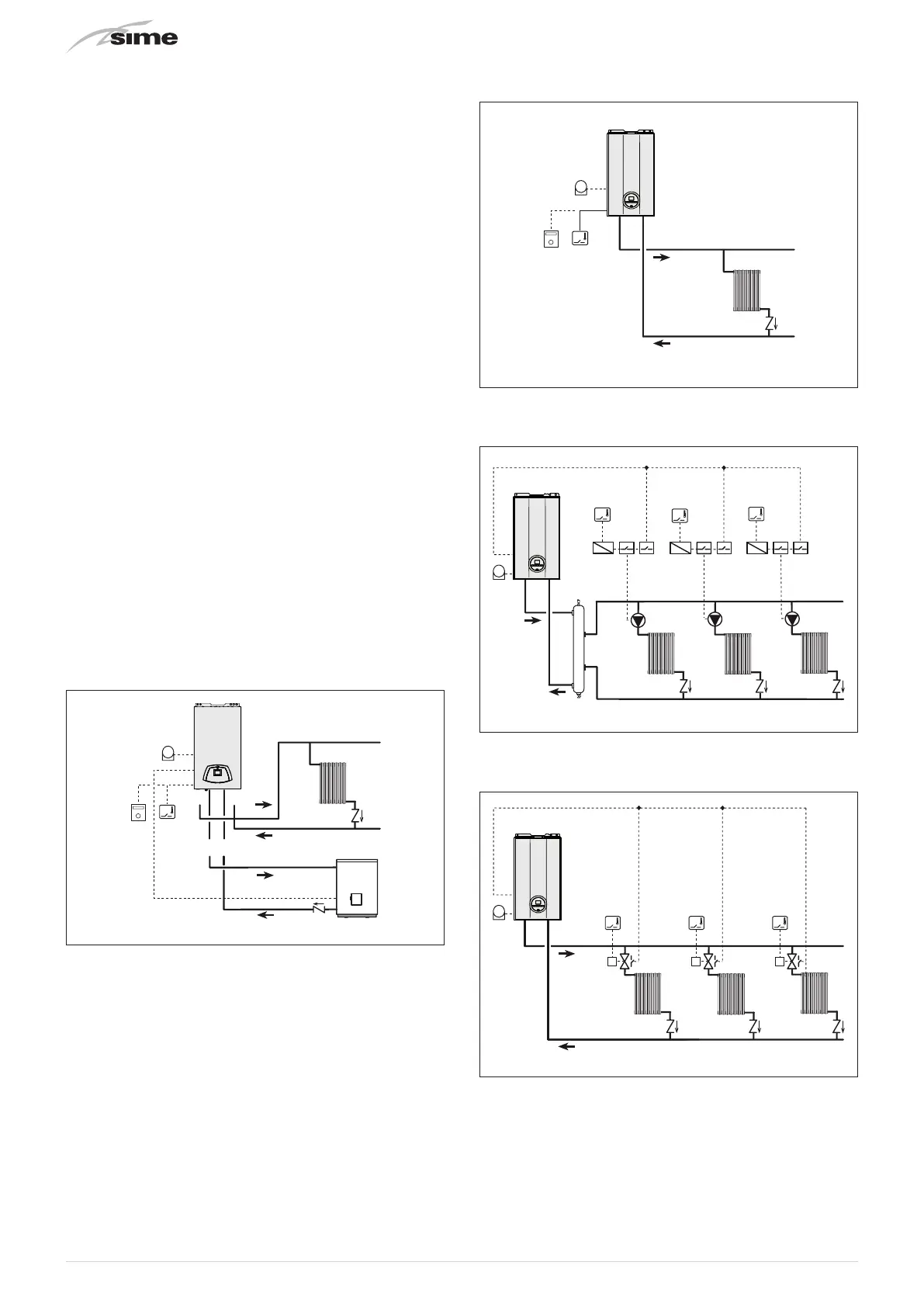

MULTI ZONE system - with pump, room thermostat and ex-

ternal sensor.

TA

TZ2

TZ3

TZ1

P3

RL1

SP

RL2 RL3

P2P1

R

M

Fig. 40

MULTI ZONE system - with zone valve, room thermostat and

external sensor.

TA

TZ1

VZ1 VZ2 VZ3

TZ2 TZ3

R

M

Fig. 41

m

CAUTION

Set the parameter "tS 17 = DELAY SYSTEM PUMP

ACTIVATION to allow the opening of zone valve Vz.

Loading...

Loading...