45

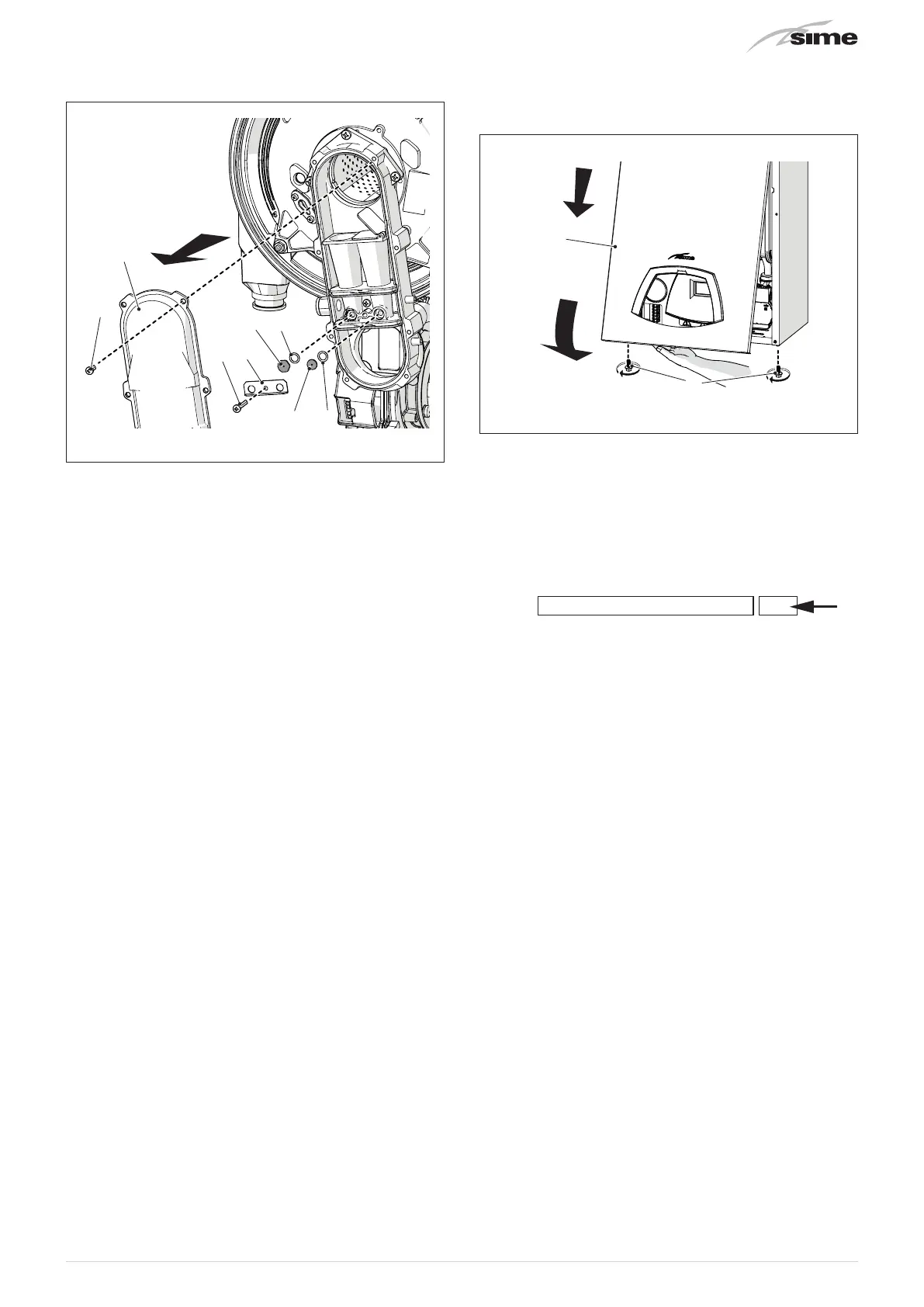

– loosen the eight screws (3) and remove the cover (4)

– unscrew the screw (5) and remove the plate (6)

7

5

6

8 9

9

3

4

Fig. 54

– replace the two distinct nozzles (7) and (8) and the related

O-ring (9) with those provided in the conversion kit. Having

two distinct nozzle heads avoids them being inverted during

assembly

– refit the plate (6) and cover (4) following the above instruc-

tions in reverse order

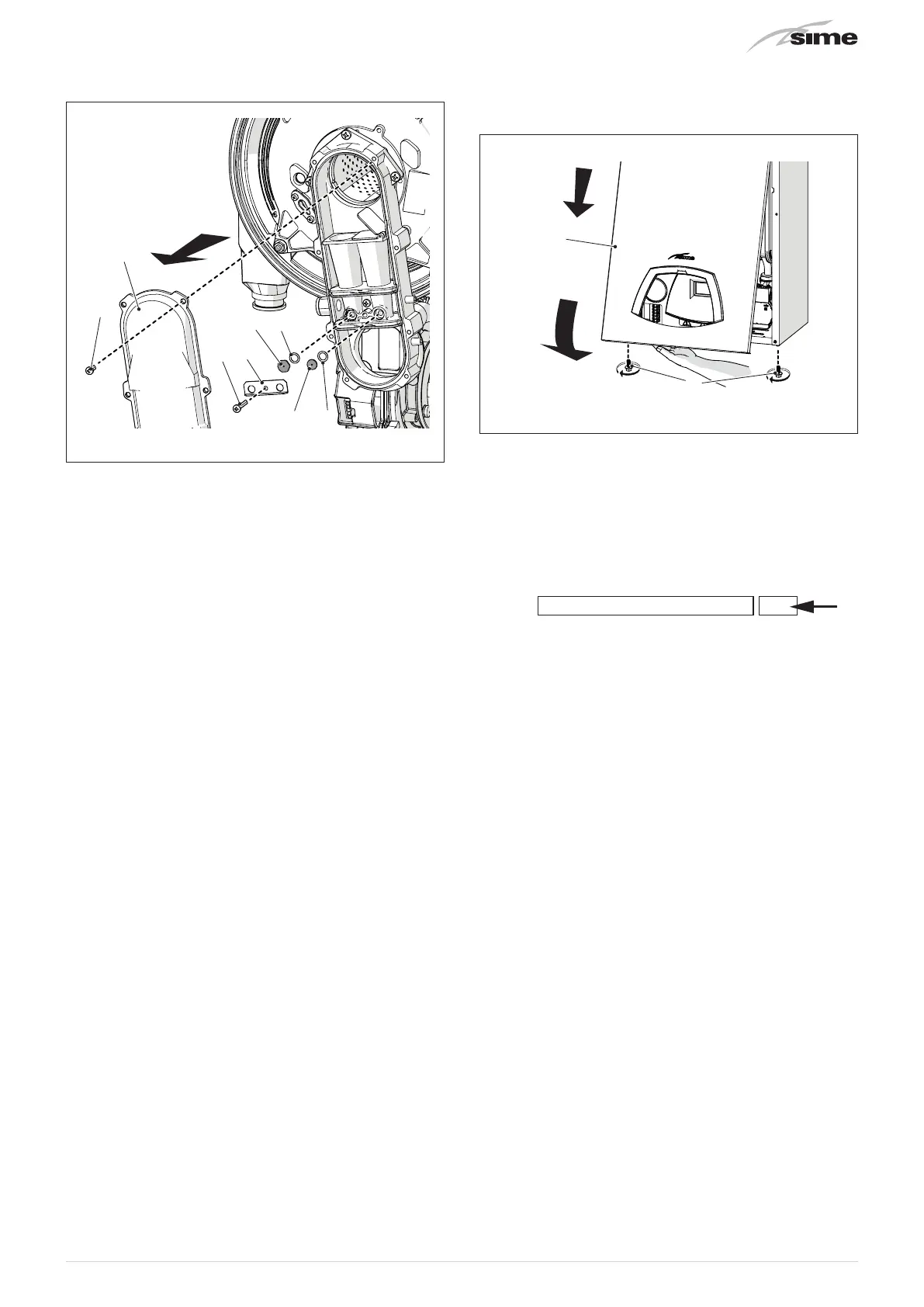

– replace the smoke outlet diaphragm, if present in the trans-

formation kit, as illustrated in "Fig. 27"

– access the installer parameters and modify parameter PAR

01 on the basis of the power and gas used, as indicated in

the table in the “Circuit Board Replacement”) paragraph

– perform the “Chimney sweep function” function to correct-

ly set the CO

2 of the boiler with the new gas and then mount

the front panel (2) back on, securing it with the two screws

(1).

2

Fig. 55

m

CAUTION

Conversion may ONLY be carried out by Profession-

ally Qualified Personnel.

m

CAUTION

If the gas supply is changed from G20 to G31, mark

the box on the TECHNICAL DATA PLATE.

G31 - 37 mbar

Loading...

Loading...