14

The TIC (except for the Network Audio Riser Controller Module) must be connected to the host

panel via RUI cabling. This section explains how to wire the two together, and how to set up a

system with multiple transponders connected to the same host panel.

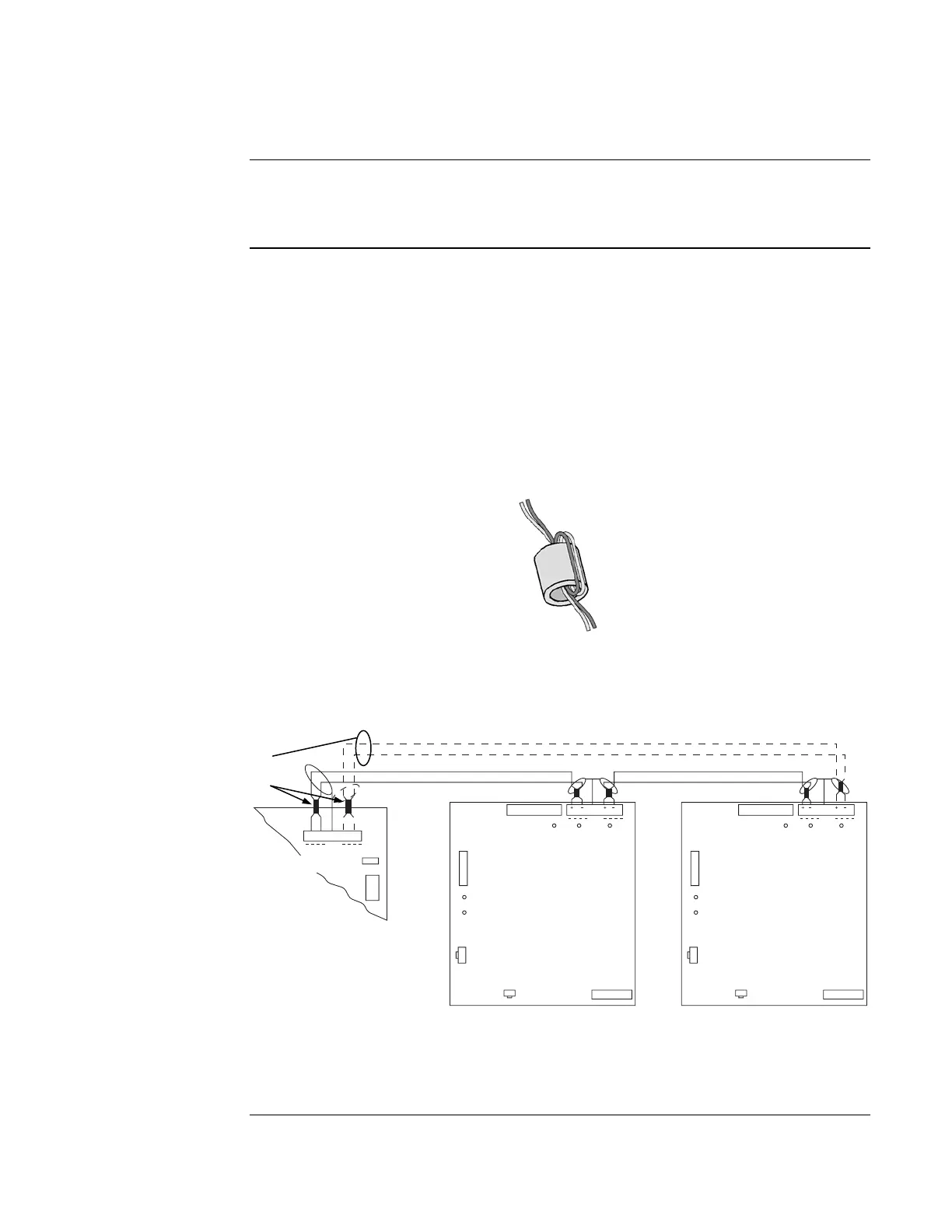

RUI cabling can be accomplished either through Class A or Class B wiring.

Class A wiring allows transponder cabinets to communicate with the FACP even in the event of

an open circuit somewhere in the loop. Class A wiring requires that two wires are routed from the

CPU motherboard to each TIC, and then back again to the CPU motherboard.

Class B wiring allows “T” tapping, and therefore requires less wiring distance per installation than

Class A. Additionally, Class B wiring does not require end-of-line resistors, because each TIC

communicates directly to the CPU.

Note: Use supplied ferrite beads with TICs. Loop wires once through the supplied

ferrite bead(s) as shown in Figure 6.

Figure 6. Loop Wiring Through Bead as Shown

Figure 7 shows both types of wiring.

TRANSPONDER INTERFACE

ASSY 566-094

MSB

LSB

LED1

ADDRESS

LED3

PRI

B+ B- SHLD A+ A-

SEC

RUI

SHLD

LED4 LED5

LED2

P1

P2 P3

RUI

P9

P1

123

TRANSPONDER INTERFACE

ASSY 566-094

MSB

LSB

LED1

ADDRESS

LED3

PRI SEC

RUI

SHLD

LED4 LED5

LED2

P1

P2

Figure 7. TIC Wiring to the Host Panel

Continued on next page

Wiring,

Continued

Overview

RUI Wiring

Configurations

DASHED LINES ARE FOR

CLASS A OPERATION

FERRITE BEADS (required)

• Wire size must be

between 18 AWG (0.8231 mm

2

)

and 12 AWG (3.309 mm

2

).

• Maximum wiring distance: 2,500 feet

(762 m).

• Maximum “T” tapping length:

10,000 feet (3,048 m).

• Maintain correct polarity on terminal

connections.

• Do not loop wires under terminals.

• Use ferrite beads as shown.

CPU

MOTHERBOARD

566-227

Loading...

Loading...