7 - 9

7 Transmission Repair

7A Tuff Torq K215A

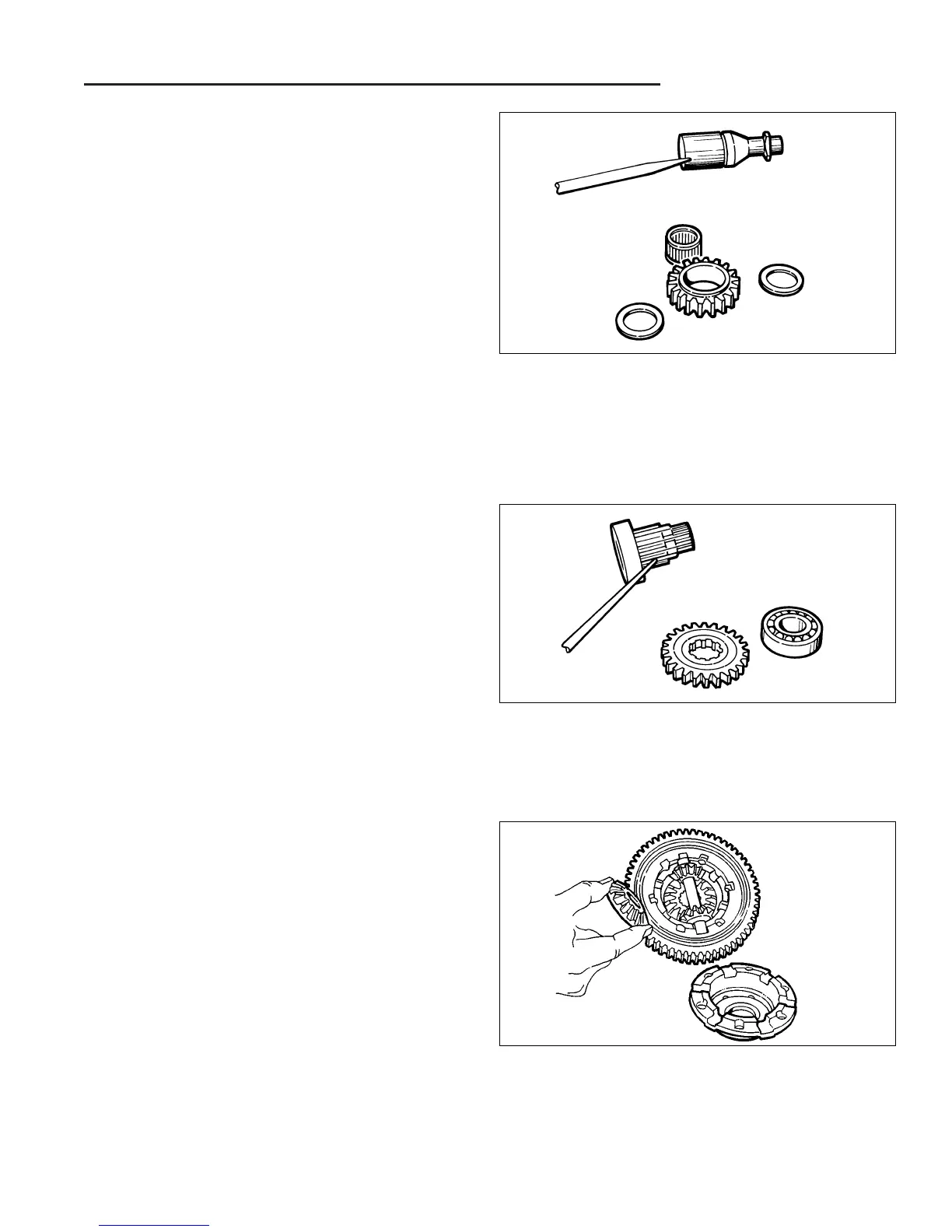

Figure A-21. Inspect Idle Shaft Components

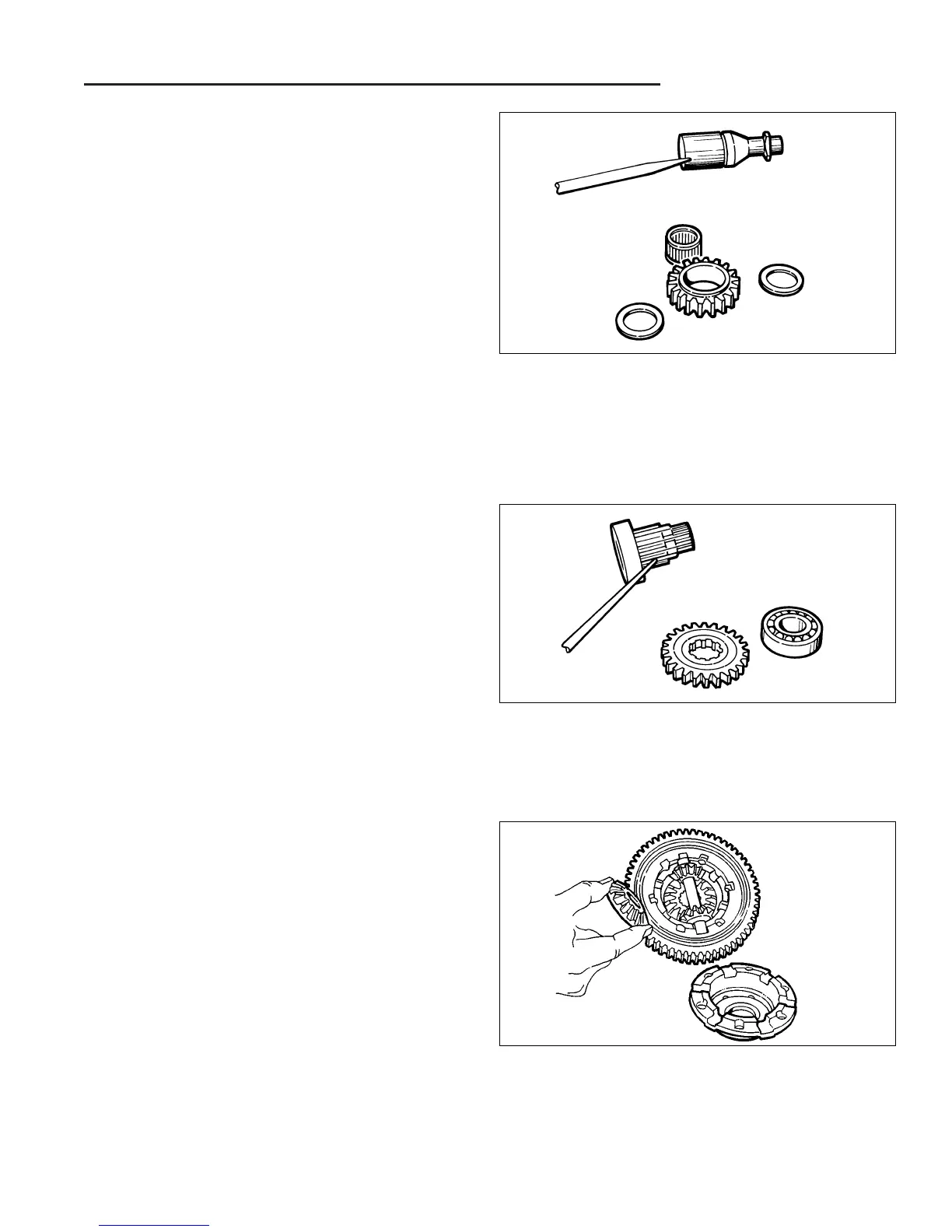

Figure A-22. Inspect Pinion Shaft and Bearings

Figure A-23. Disassemble Differential Assembly

29. Check the idle shaft, needle bearing, gear and thrust

washers.

NOTE: The washers have oil control grooves to assure

lubrication of the needle bearing. If worn parts appear

questionable, tolerances can be checked according to

specifications.

Specifications:

Idle shaft O.D. .............................................. 0.866 in.

Gear I.D. ...................................................... 1.103 in.

Washer thickness .............................. 0.094-0.102 in.

30. Inspect the final pinion shaft and bearings for wear.

31. Loosen and remove six bolts and nuts from differen-

tial assembly. Do not reuse this hardware. Always

use new parts here.

32. As you disassemble the differential, note the pinion

shaft can only fit into the drive gear in one position.

NOTE: The cover is notched to accommodate the pinion

shaft.

Loading...

Loading...