LUBRICATION

Pour

"TYPE

H"

OIL

into

Oil Filler Cup

~

Keep

Oil

ih

Sight

Gaug,!.at

''FULL''

MARK

\

f

QS

Check

Oil

Level

DAILY

BEFORE

STARTING

MACHINE

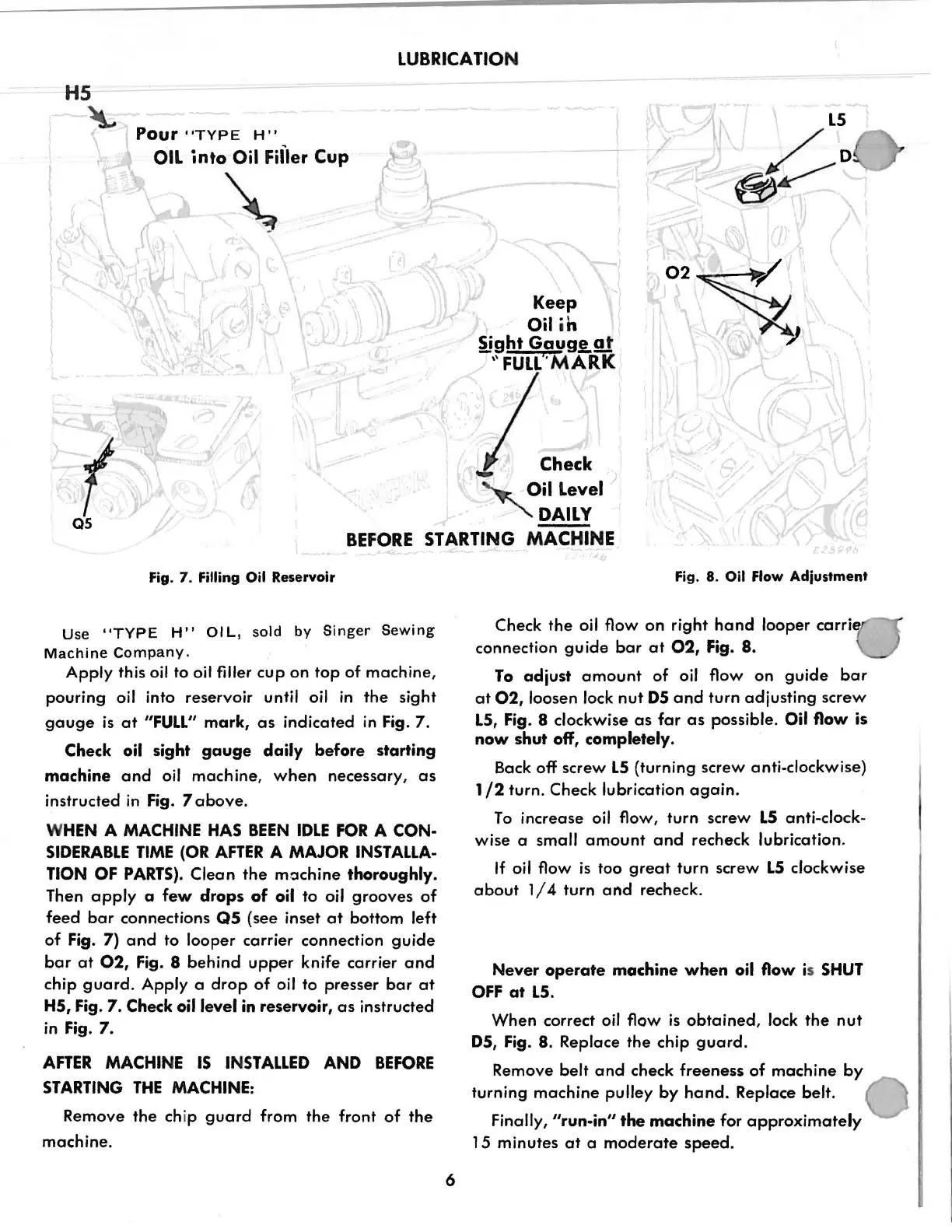

Fig. 7. Filling Oil Reservoir

Use

"TYPE

H"

OIL,

sold

by

Singer

Sewing

Machine

Company.

Apply this oil to oil filler

cup

on

top

of machine,

pouring

oil into reservoir until oil

in

the

sight

gauge

is

at

"FULL"

mark,

as

indicated

in

Fig. 7.

Check oil sight

gauge

daily

before

starting

machine

and

oil machine,

when

necessary,

as

instructed

in

Fig. 7

above.

W

HEN

A

MACHINE

HAS

BEEN

IDLE

FOR

A CON-

SIDERABLE

TIME

(OR

AFTER

A MAJOR

INSTALLA-

TION OF

PARTS).

Clean

the

machine

thoroughly.

Then

apply

a

few

drops

of

oil to oil

grooves

of

feed

bar

connections

QS

(see inset

at

bottom left

of Fig. 7)

and

to looper carrier connection

guide

bar

at

02,

Fig. 8

behind

upper

knife carrier

and

chip

guard.

Apply a

drop

of

oil to presser

bar

at

HS, Fig.

7.

Check oil level in reservoir,

as

instructed

in

Fig. 7.

AFTER

MACHINE

IS

INSTALLED

AND

BEFORE

STARTING

THE

MACHINE:

Remove

the

chip

guard

from the front

of

the

machine.

6

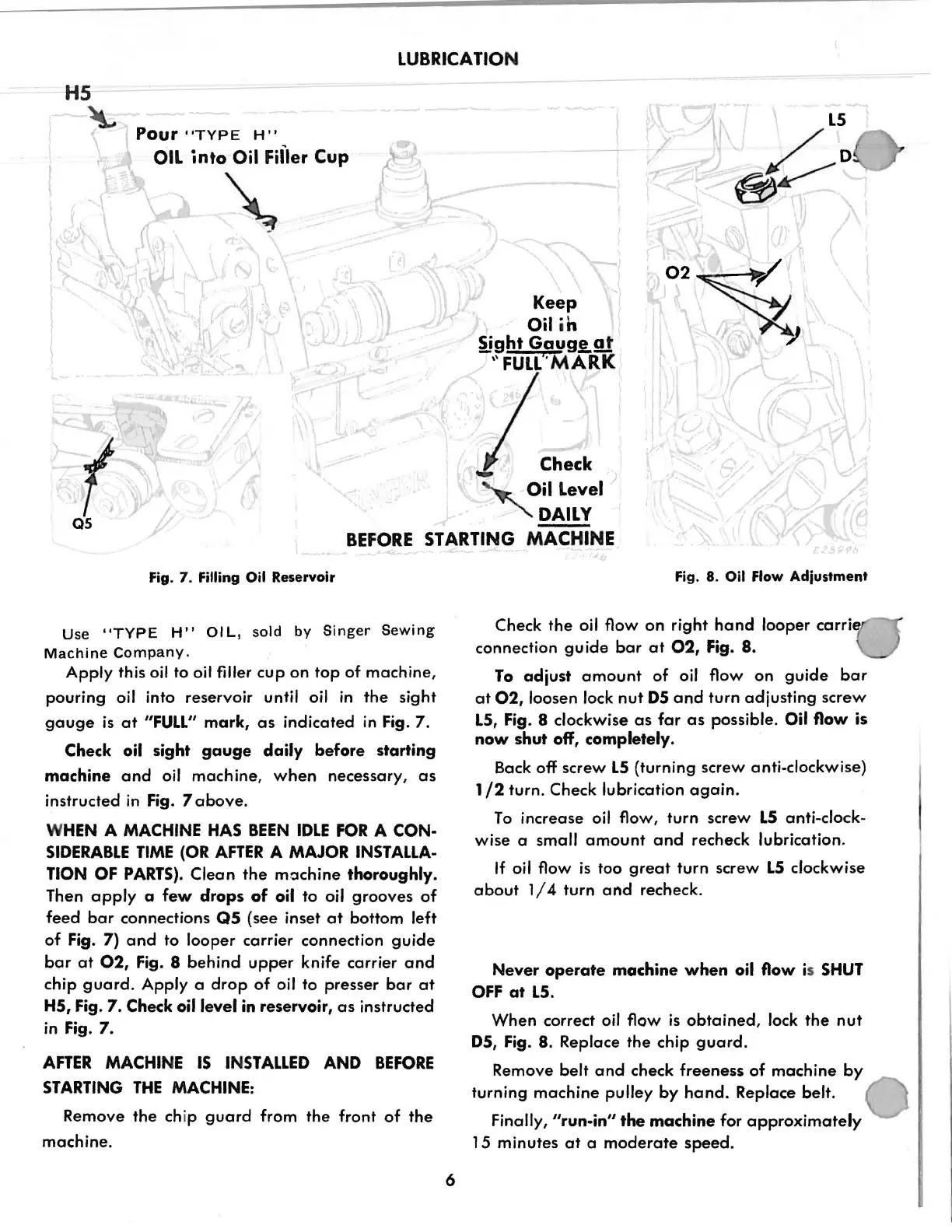

Fig. 8. Oil Flow Adjustment

Check

the

oil flow on right

hand

looper

carrie

connection

guide

bar

at

02,

Fig. 8.

To

adjust

amount

of

oil flow on

guide

bar

at

02,

loosen lock

nut

DS

and

turn

adjusting

screw

LS,

Fig. 8 clockwise

as

far

as

possible. Oil flow is

now

shut

off, completely.

Back off screw

LS

(turning screw anti-clockwise)

1

/2

turn. Check lubrication

again.

To

increase oil flow, turn screw

LS

anti-clock-

wise a small

amount

and

recheck lubrication.

If

oil flow

is

too

great

turn screw

LS

clockwise

about

1/4

turn

and

recheck.

Never

operate

machine

when

oil flow is

SHUT

OFF

at

LS.

When correct oil flow

is

obtained,

lock

the

nut

DS,

Fig. 8. Replace the chip

guard.

Remove belt

and

check

freeness

of machine

by

turning

machine

pulley

by

hand.

Replace belt.

Finally,

"run-in"

the

machine

for

approximately

15 minutes

at

a

moderate

speed.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...