SPEED

___

MAXIMUM

- SPEEDt=

Speed

-recommenelecl

MACHINE

246K42

46K43

246K45

(Stitches

per

for Long Runs

or

while

minute)

sewing

long stitches

6000

6000

5500

5500

5500

5000

tMaximum

efficient

speed

is

dependent

upon

the

ability

of

the

operator,

the

nature

of

the

operation

and

the type

of

material

being sewn.

It

is

advisable

to

operate

these

machines

at

more

moderate

speeds

the

first

few

days,

after

which

they

can

be

run

at

top speed.

When

the

machine

is

in

operation,

top

of

ma-

chine pulley must

always

turn over

away

from

operator.

NEEDLES

AND

THREAD

Needles

are

of curved

blade,Catalogue#1265

(151

x

7)

regular,

in

sizes 9 to

12,

14, 16,

18,

19

and

21.

Needles

of

Catalogue#1263

(151 x 3)

with

tapered

blade,

in

sizes 5, 6, 7, 9

and

11

are

available.

Selection of

needles

can

make

a

great

differ-

ence

in

the

ease

and

quality

of

the work.

It

is

im-

portant

that

each

needle

be

just right for machine,

thread

and

work being

done.

Choose

your

needle

carefully. The correct size

will permit

thread

to

pass

freely through

needle

eye;

avoiding

strain

and

breakage

of

thread.

twist or left twist

thread

may

be

If

trouble

occurs during sewing:

Inspect needle point. A hook or burr

may

cause

poor stitching

or

some materials

may

be

cut

when

short stitches

are

used.

Check

curvature

of

each

needle,

as

instructed

below. Unless

the

needle

has

the correct

curva-

ture, it

may

cause

skipping

of

stitches.

Orders for needles must specify the

Quantity

required, the Size number, also the

Catalogue

number

...

For

exam

pie

...

"100

Size

9,

Catalogue#1265 (

151

x

7)

Needles."

The best stitching results will

be

obtained

when

using needles sold by Singer Sewing

Machine

Company.

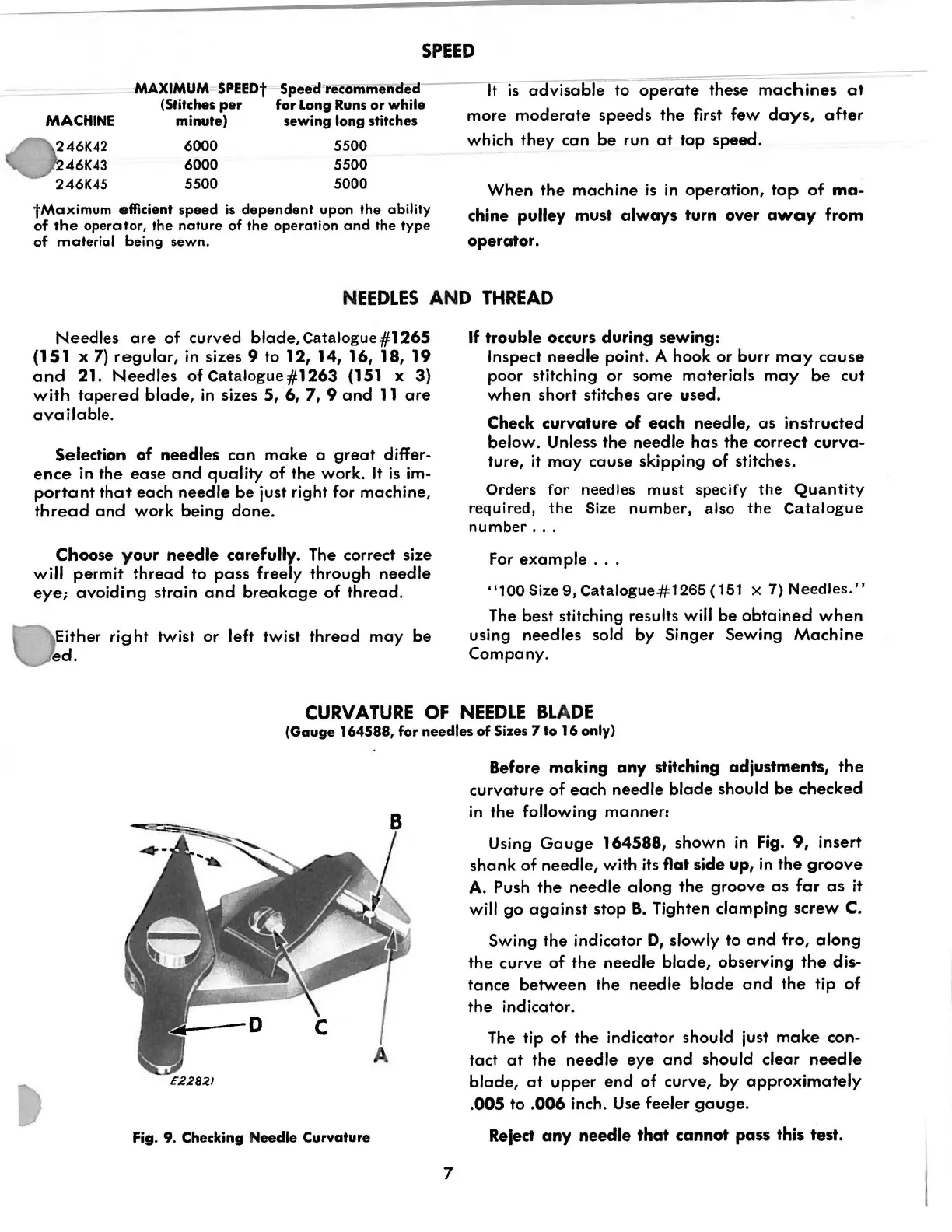

CURVATURE

OF

NEEDLE

BLADE

(Gauge

164588, for

needles

of Sizes 7

to

16

only)

Fig.

9.

Checking Needle Curvature

7

Before

making

any

stitching

adiustments,

the

curvature

of

each

needle

blade

should be

checked

in

the

following

manner:

Using

Gauge

164588,

shown

in

Fig.

9,

insert

shank

of

needle, with its flat

side

up,

in

the

groove

A.

Push

the

needle

along

the

groove

as

far

as

it

will

go

against

stop

B.

Tighten clamping

screw

C.

Swing the indicator

D,

slowly to

and

fro,

along

the

curve

of

the

needle

blade,

observing

the

dis-

tance

between

the needle

blade

and

the tip

of

the indicator.

The tip

of

the

indicator should just

make

con-

tact

at

the

needle

eye

and

should clear

needle

blade,

at

upper

end

of

curve,

by

approximately

.005

to

.006

inch. Use feeler

gauge.

Reied

any

needle

that

cannot

pass

this test.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...