Page 15/38

7. Clearance between needle and shuttle

Make this checking before checking “Needle timing to shuttle”.

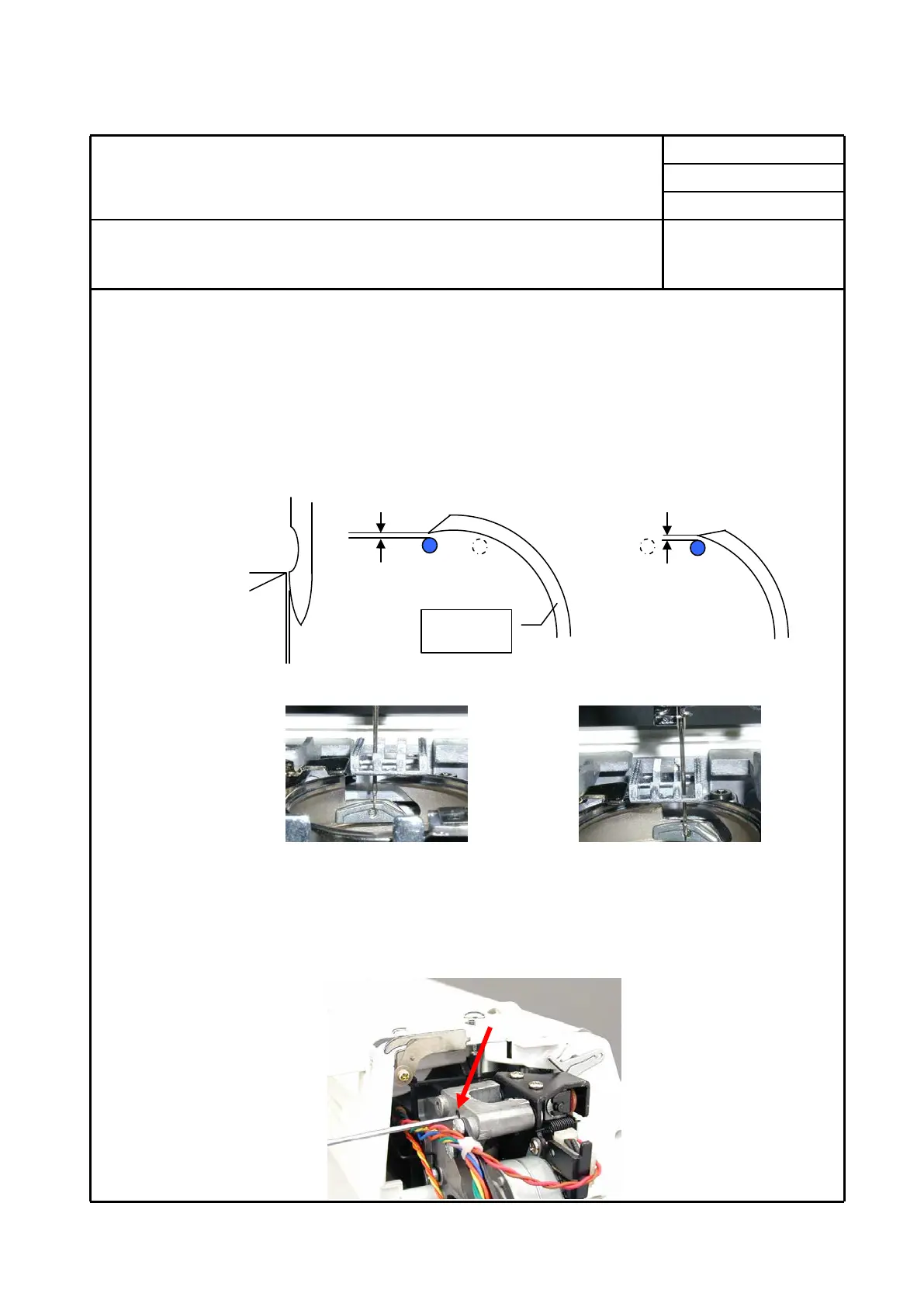

Checking:

1. Select widest zigzag stitch.

2.

Remove needle plate, bobbin case and face cover.

3. Shift shuttle hook at the rear of needle by turning hand wheel.

Check to see if needle clearance to shuttle is within 0.05 to 0.15 mm.

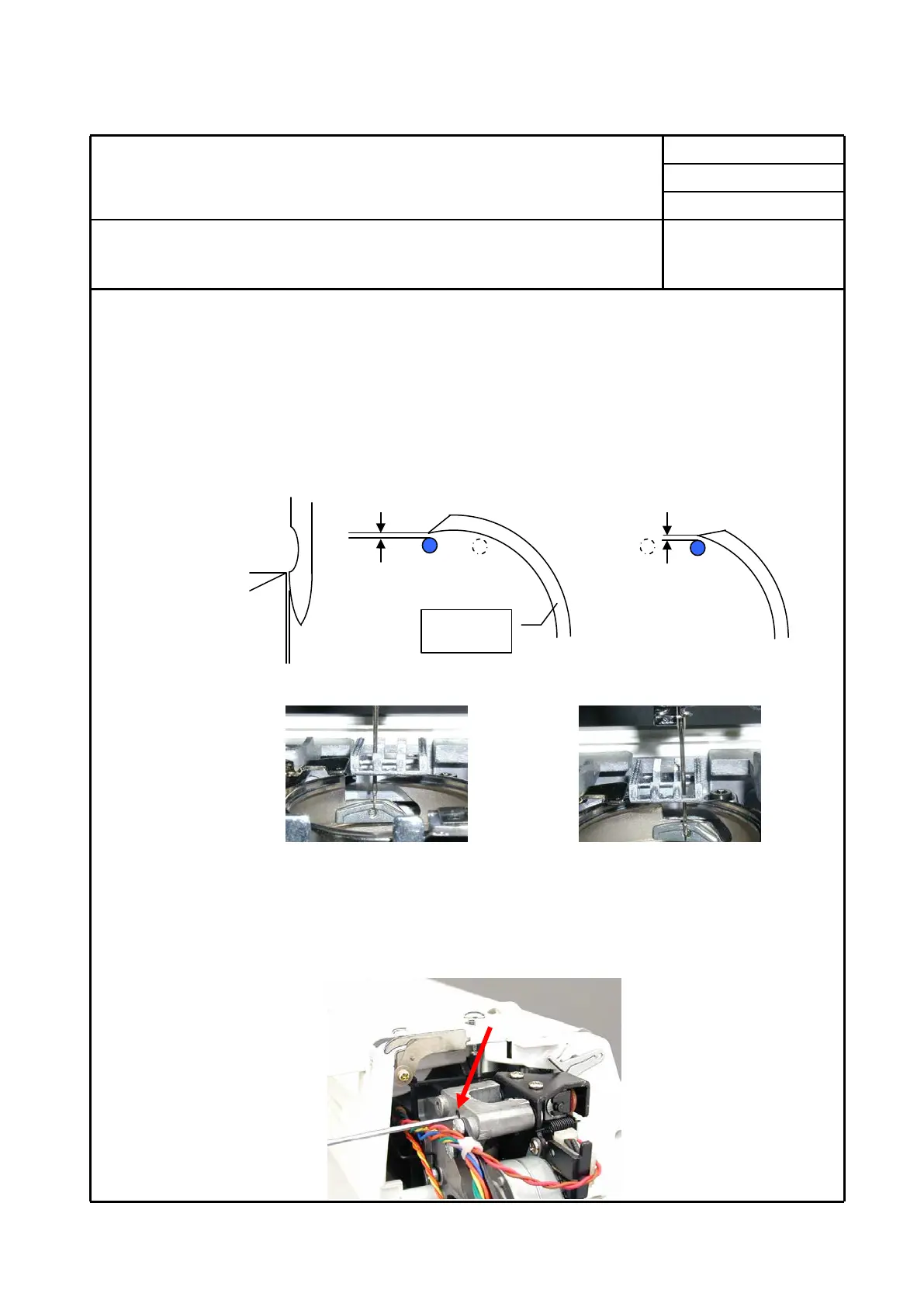

Adjustment:

1. Turn screw (A) to either direction as illustrated and adjust needle position by moving

support shaft back and forth. To decrease clearance, turn screw counter-clockwise.

Shuttle

0.05

0.15

0.05

0.15

At left position

At right position

0.05

0.15

At left position At right position

A

Loading...

Loading...