© Jun 2020 9-2 GTJZ0612E&0812E&1012E&1212E Operation Manual

MAINTENANCE

2. Use the following table to note the results. After

each section is complete, mark the appropriate box.

3. Record the inspection results. If any inspection re-

sults are "NO", the machine must be stopped and

re-inspected after repair is completed and marked

in the box marked "inspection".

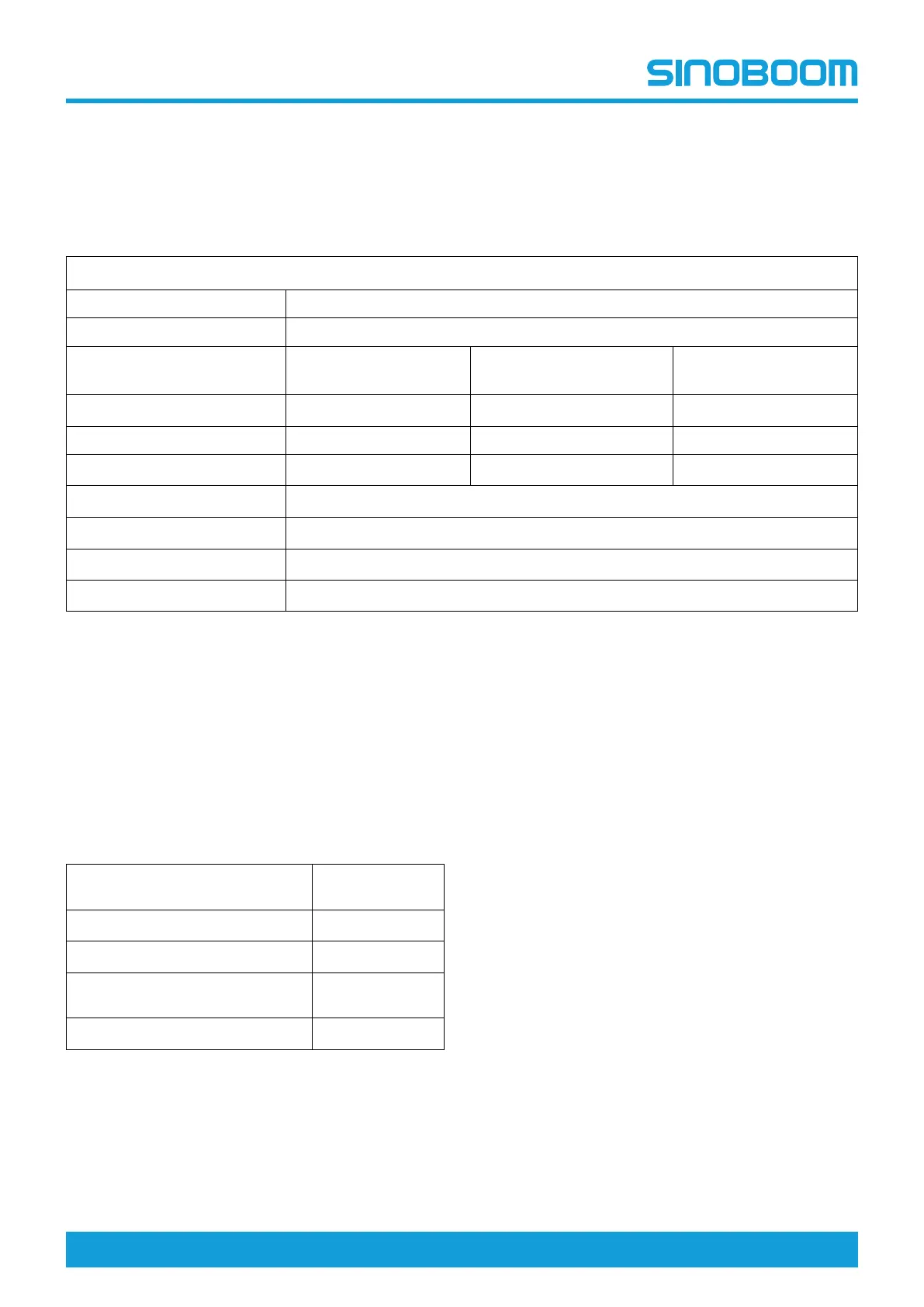

Table 9-1

PREPARE THE WORK RECORD BEFORE DELIVERY

Model

Serial No.

Inspection Item

YES/Machine is in

Good Condition

NO/Machine Has Damage

or Malfunction

REPAIRED/Machine

Has Been Repaired

Pre-operational Inspection

Maintenance Procedure

Functional Inspection

Machine Buyer/ Renter

Inspector Signature

Inspector Title

Inspector Company

FOLLOWING A

MAINTENANCE SCHEDULE

Regular maintenance inspections must occur daily,

quarterly, biannually (every 6 months) and annually.

Use the table to help you adhere to a routine mainte-

nance schedule.

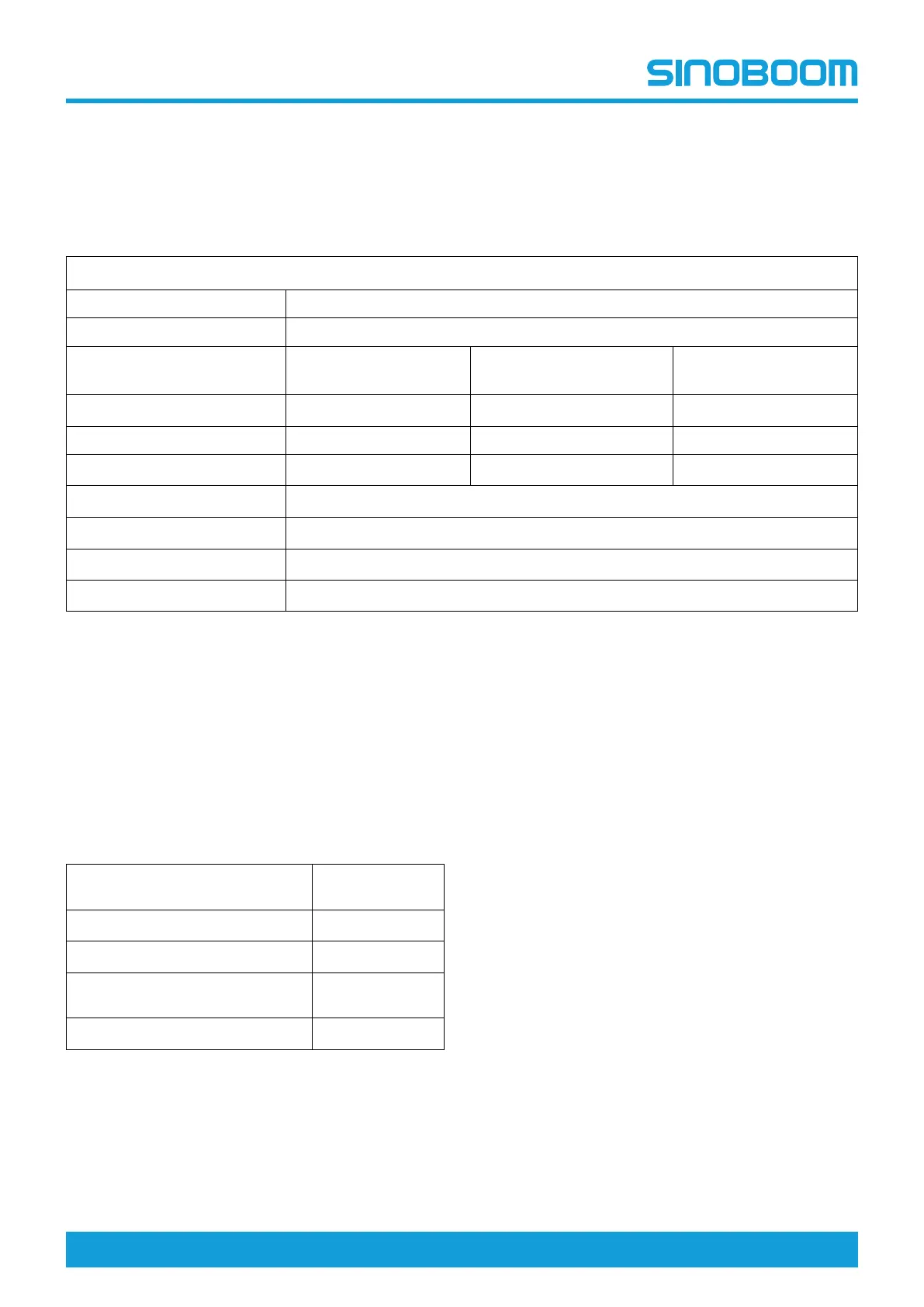

Table 9-2

INSPECTION INTERVAL

INSPECTION

PROCEDURES

Every day or every 8 hours

A

Every quarter or every 250 hours

A+B

Every half a year or every 500

hours

A+B+C

Every year or every 1000 hours

A+B+C+D

COMPLETING A REPAIR &

INSPECTION REPORT

1. Divide the Repair & Inspection Report into four sec-

tions (A, B, C and D) according to the time require-

ments of the maintenance schedule and the

maintenance procedure requirements.

2. The Repair & Inspection Report shall include the in-

spection table of each regular inspection.

3. Duplicate the Repair & Inspection Report for each

inspection. Store the completed tables for 10 years

or until the machine is no longer in use or as re-

quired by machine owner/company/custodian.

4. Use the following table to note the results. After

each section is complete, mark the appropriate box.

5. Record the inspection results. If any inspection re-

sults are "NO", the machine must be stopped and

re-inspected after repair is completed and marked

in the box marked "inspection". Select the appropri-

ate inspection procedure based on the inspection

type.

Loading...

Loading...