18

ASSEMBLY INSTRUCTIONS….cont

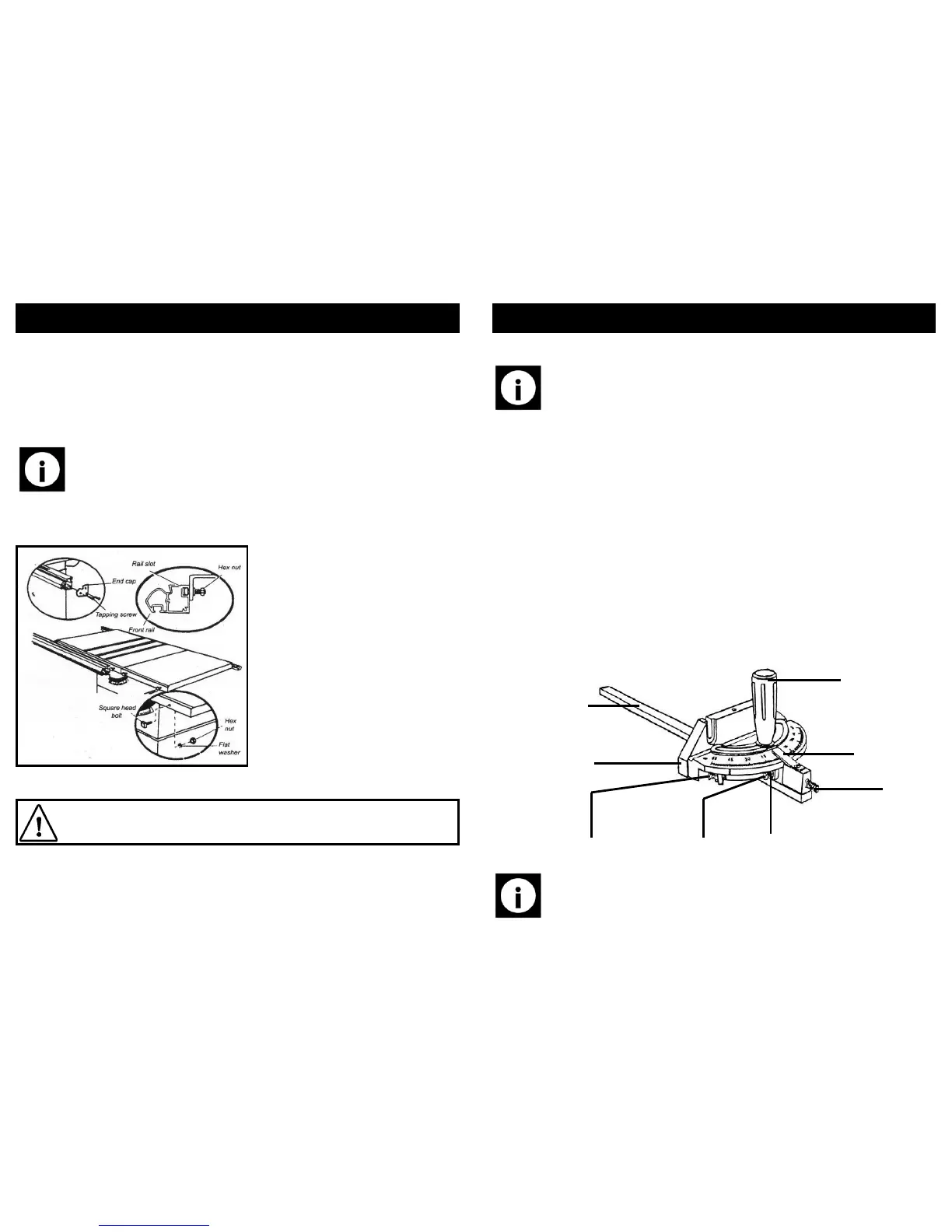

• Insert the 5 square head bolts into the holes on the front of the main table and

extension tables, so the bolt heads extend out 6 mm.

• Loosely attach a flat washer and a hex nut to each bolt.

• Slide the slot on the front fence rail over bolts until the rail is in its correct posi-

tion.

• Adjust each bolt to fit the rail closely to the table.

• Push the rear fence rail against table and hand tighten each hex nut.

Note: Ensure there are no gaps between the rail and the edge of the main

table or extensions.

• Fit the end caps on the rail ends, secure them with the self-tapping screws and

tighten with Phillips screwdriver.

Fitting the rear fence rail:

Caution! The front and rear rails must be carefully aligned to reduce the risk

of kickback, which can cause serious injury.

• To install the rear rail will require the following hardware:

⇒ 5 x square head bolt.

⇒ 5 x 8 mm flat washer.

⇒ 5 x M8 hex nuts.

27

CARE AND MAINTENANCE….cont

• Adjust the distance between the blade and the riving knife (b).

Note: The gap should be between 3 mm and 8 mm.

• Once the gap has been correctly set, re-tighten the nut (a).

• Re-install the table insert and blade guard.

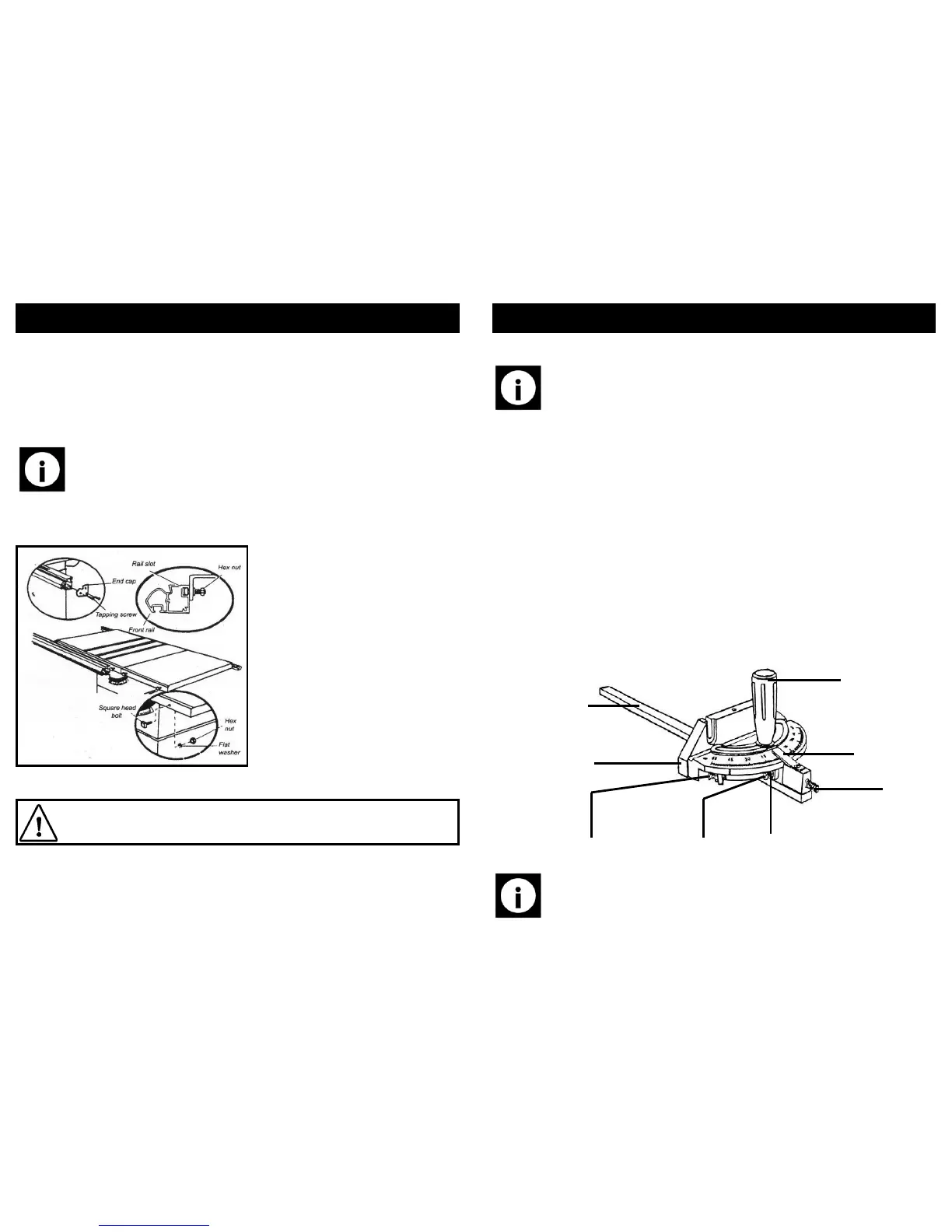

Adjusting the mitre gauge angle:

The mitre gauge has quick set stops at 0° and +/- 45° with the mitre gauge stop pin

and adjustable stop screws. The stop screws are factory set for accuracy but after time

and use, the gauge may need to be re-set, this can be achieved by the following:-

• Loosen the angle lock knob and pull out the stop pin.

• rotate the mitre gauge until the stop pin rests against the 0° stop screw.

• Place a 90° square against the mitre gage rod and the mitre gauge base.

• If the rod is not square, Loosen the lock nut of the 0° stop screw 8 mm wrench.

• Adjust the 0° stop screw until a true 90° angle is achieved.

• Tighten the lock nut to secure, and adjust the angle pointer to read 0°.

• Adjust the plus and minus 45° stop screws using a 45° triangle and the steps

above.

Mitre gauge rod

Angle lock knob

Stop pin

Mitre gauge base

45° stop screw

0° stop screw 0° lock nut

Angle pointer

Note: The mitre gauge provides close accuracy for angled cuts, for very

close tolerances, test cuts are recommended.

Loading...

Loading...