38

Ref. No. Description Qty.

B-63 Motor Wheel 1

B-64 Hexagon Socket Cap Head Screw M8X24 7

B-65 Single Coil Spring Lock Washer 8 7

B-66 Rotation Press Block 2

B-67 Adjusting Cradle 1

B-69 Hexagon Nut M12 1

B-70 Single Coil Spring Lock Washer 12 1

B-71 Worm- Wheel 1

B-72 Eccentric Sleeve 1

B-73 Hexagon Socket Cap Head Screw M8X30 1

B-74 Worm- Wheel Shaft Nail 1

B-75 Locking Block 1

B-76 Large Washer 8 2

B-77 Flower Bolt 1

B-78 Cross Recessed Pan Head Screw M5X12 2

B-79 Pointer Bracket 1

B-80 Pointer 1

B-81 Flat Washer 4 1

B-82 Single Coil Spring Lock Washer 4 1

B-83 Cross Recessed Pan Head Screw M4X10 1

B-84 Adjusting Worm-Wheel Bracket 1

B-85 Dust Collection Cover 1

B-86 Hexagon Socket Cap Head Screw M6X18 3

B-87 Neck Chain 1

B-88 Hexagon Head Bolt M6X25 2

B-89 Dust Collection Tube 1

B-90 Elliptic Neck Chain 1

B-91 Cross Recessed Countersunk Head Tapping Screw 5

B-92 Spanner Shaft 1

B-93 Hexagon Nut M5 1

PARTS LIST (B)

7

SAFETY SYMBOLS

When using the saw always ensure the operator as well as those in the

area wear ear protection.

When using the saw always ensure the operator as well as those in the

area wear eye protection.

Some wood and wood composites have the potential to be highly

toxic; always wear a face mask when operating saw.

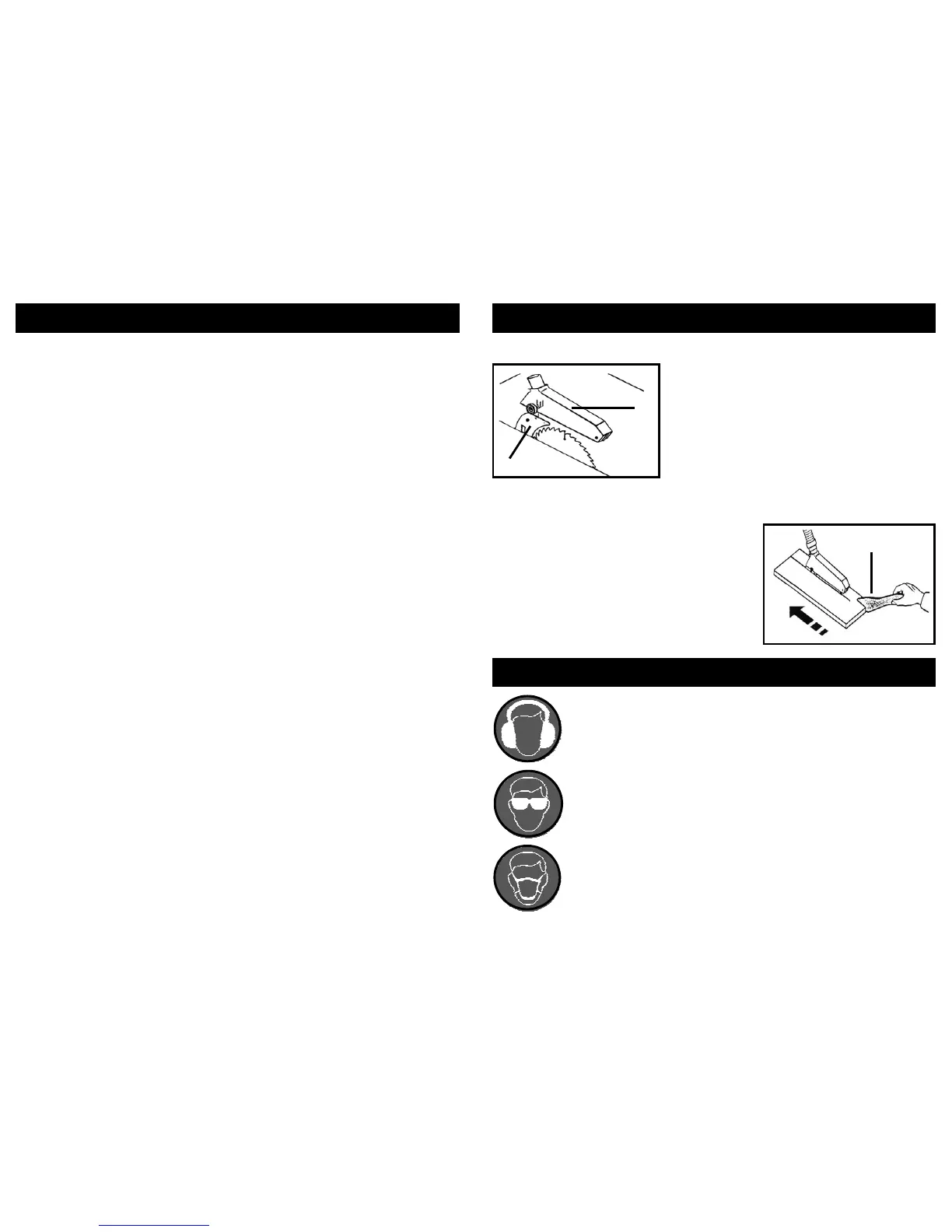

SAFETY DEVICES

Blade guard:

A

B

• The blade guard (a) protects against uninten-

tional contact with the saw blade and from air-

borne chips / debris.

• The riving knife (b) prevents the work-piece

from being caught on the rising teeth of the

saw blade and being thrown against the opera-

tor.

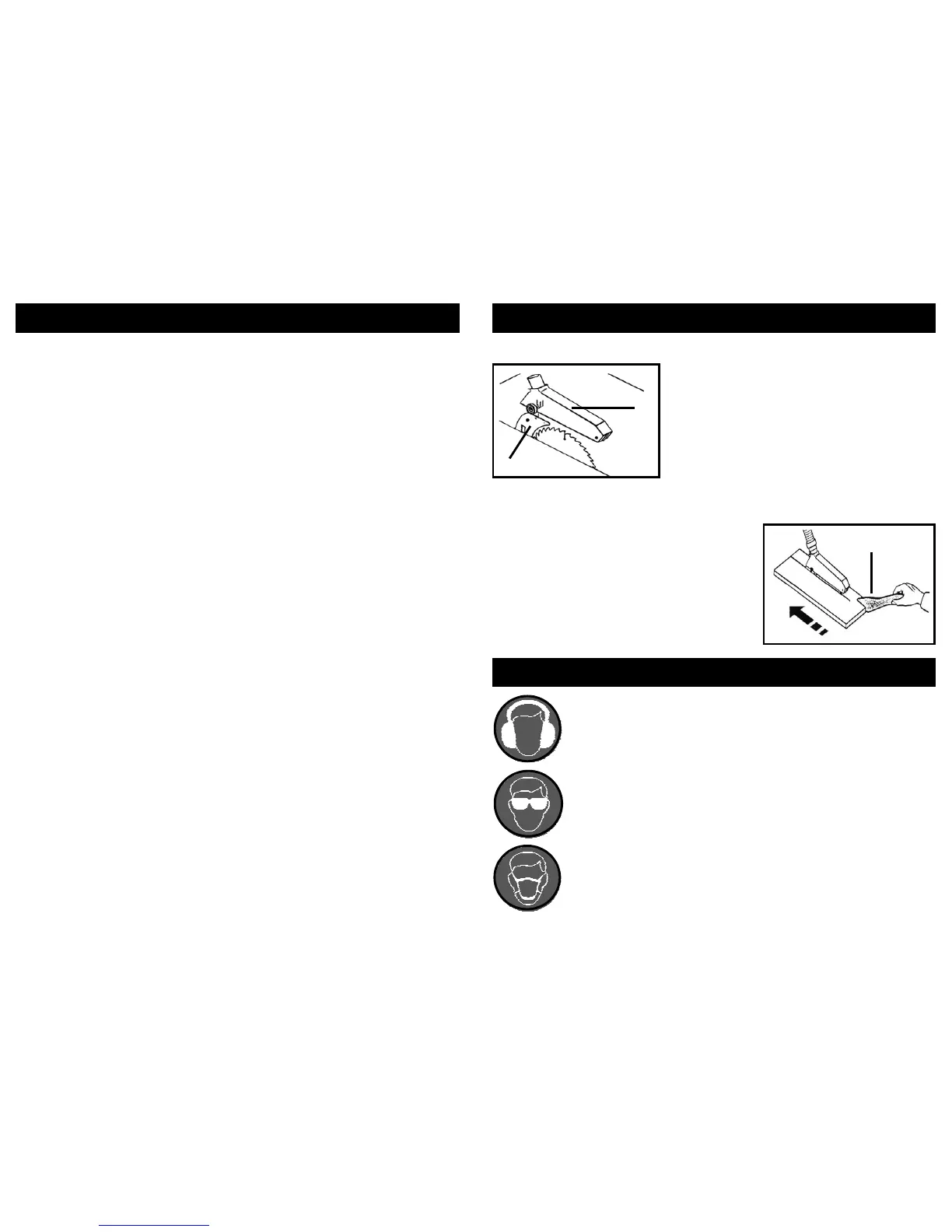

• The push stick (p) serves as an extension of

the hand and protects against accidental con-

tact with the saw blade.

• Use push stick particularly if distance be-

tween rip fence and the saw blade is below

120 mm.

• In order for the push stick to be always at

hand, it should be stored within easy reach of

the machine.

P

Note: Always have riving knife and blade guard installed during operation.

Loading...

Loading...