(W3) Suspension Springs

With engine OFF, visually inspect sus-

pension springs. Replace any weak or

broken spring.

(W4) Track

Lift the rear of the vehicle and support it

off the ground

so

that the track is free to

turn. With engine turned

OFF,

rotate track

by hand and

v1sually inspect track con-

dition.

If

bad cuts or missing inserts (See

Glossary, page 30) are noted, see your

dealer.

Note:

Without these inserts continual

abrasion would wear and cut the track

therefore, always replace

a missing or

damaged insert

as

soon

as

possible.

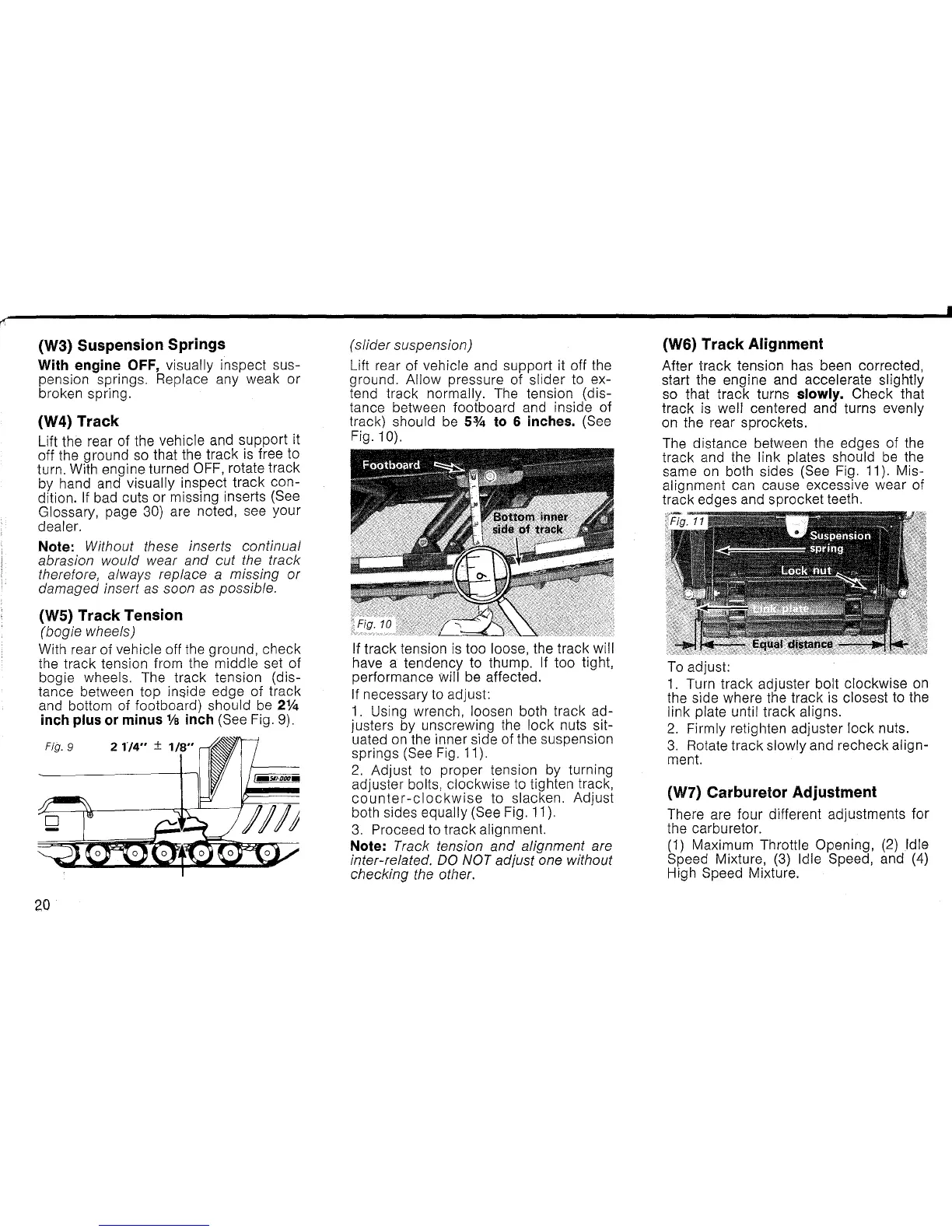

(W5) Track Tension

(bogie wheels)

With rear of vehicle off the ground, check

the track tension from the middle set of

bogie wheels. The track tension (dis-

tance between top inside edge of track

and bottom of footboard) should

be

2%

inch plus or minus

Va

inch (See Fig. 9).

Fig. 9

21'/4"

±

1/8"

20

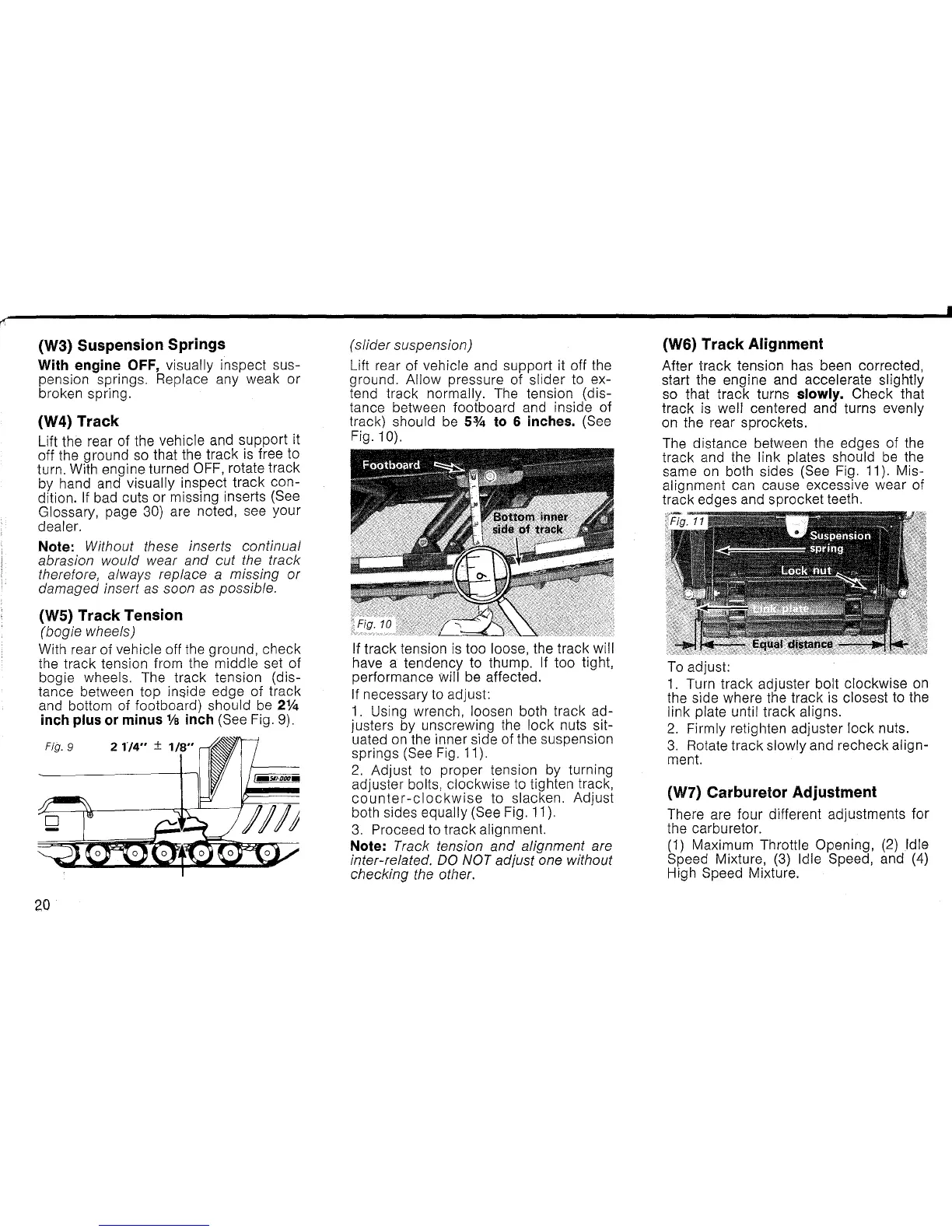

(slider suspension)

Lift rear of vehicle and support it off the

ground.

Allow pressure of slider

to

ex-

tend track

normally. The tension (dis-

tance between footboard and inside of

track) should

be

5

3

,4

to

6 inches. (See

Fig. 10).

If track tension is too loose, the track will

have a tendency to thump.

If

too tight,

performance

will be affected.

If

necessary

to

adjust:

1.

Using wrench, loosen both track ad-

justers by unscrewing the lock nuts sit-

uated

on

the inner side of the suspension

springs

(See

Fig.

11).

2.

Adjust

to

proper tension by turning

adjuster bolts, clockwise

to

tighten track,

counter-clockwise

to slacken. Adjust

both sides

equally (See Fig. 11).

3.

Proceed to track alignment.

Note:

Track tension

and

alignment are

inter-related.

DO

NOT adiust one without

checking the other.

(W6) Track Alignment

After track tension has been corrected,

start the engine and accelerate slightly

so

that track turns slowly. Check that

track is

well centered and turns evenly

on

the rear sprockets.

The distance between the edges of the

track and the link plates should

be

the

same

on

both sides (See Fig. 11). Mis-

alignment can cause excessive wear of

track edges and sprocket teeth.

To

adjust:

1.

Turn track adjuster bolt clockwise

on

the side where the track is closest to the

link plate until track aligns.

2.

Firmly retighten adjuster lock nuts.

3.

Rotate track slowly and recheck align-

ment.

(W7) Carburetor Adjustment

There are four different adjustments for

the carburetor.

(1)

Maximum Throttle Opening,

(2)

Idle

Speed Mixture,

(3)

Idle Speed, and

(4)

High Speed Mixture.

•

Loading...

Loading...