, .

Maximum Throttle Opening

With engine

OFF,

unscrew the Idle Speed

Adjusting screw

until a gap exists be-

tween screw end and carburetor shaft

lever.

Depress

the

throttle

lever

at

handlebar and hold. Throttle butterfly

should

be horizontal when the lever gent-

ly

touches the handlebar grip.

To

adjust for maximum opening, loosen

screw at point where cable joins carbu-

retor

lever.

With finger, hold carburetor throttle lever

in

fully open position (UP), pull cable

downward until taut. Retighten screw,

ensuring throttle

is

fully depressed.

WARNING: Before starting engine,

make sure carburetor throttle

lever

returns

to

idle position when handlebar

throttle

lever

is

released.

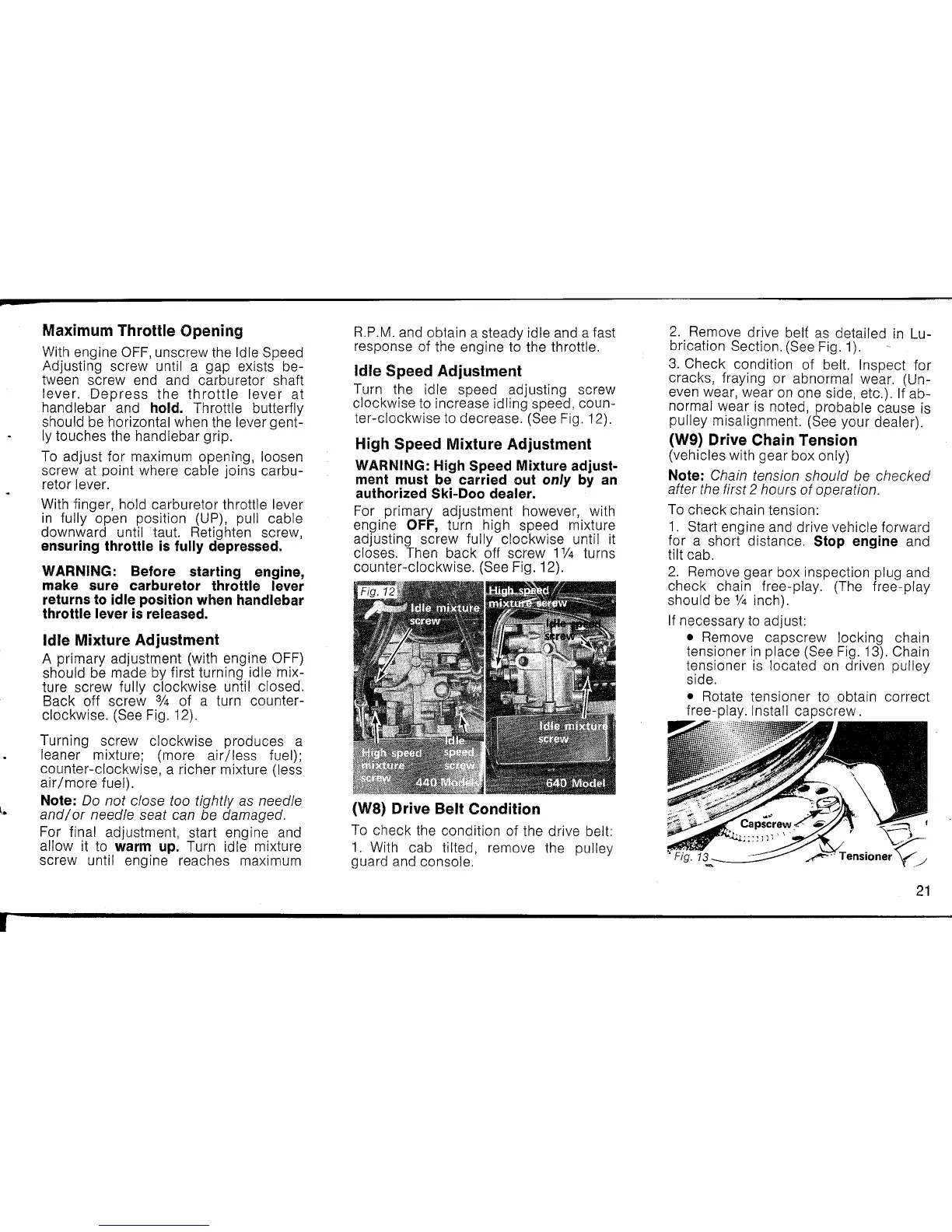

Idle Mixture Adjustment

A primary adjustment (with engine OFF)

should

be made by first turning idle mix-

ture screw fully

clockwise until closed.

Back off screw

3f4

of a turn counter-

clockwise. (See Fig. 12).

Turning screw

clockwise produces a

leaner mixture; (more

air/less

fuel);

counter-clockwise, a richer mixture (less

air/more

fuel).

Note: Do

not

close too tightly as needle

and/or

needle seat can

be

damaged.

For final adjustment, start engine and

allow it to

warm

up.

Turn idle mixture

screw

until engine reaches maximum

R.P.M. and obtain a steady

idle and a fast

response of the engine to the

throttle.

Idle Speed Adjustment

Turn the idle speed adjusting screw

clockwise to increase idling speed, coun-

ter-clockwise to decrease. (See Fig. 12).

High Speed Mixture Adjustment

WARNING: High Speed Mixture adjust-

ment must be carried out only

by

an

authorized Ski-Doo dealer.

For primary adjustment however, with

engine OFF, turn high speed mixture

adjusting screw fully

clockwise until it

closes. Then back off screw 1

V4

turns

counter-clockwise. (See Fig. 12).

(W8) Drive Belt Condition

To

check the condition of the drive belt:

1.

With cab tilted, remove the pulley

guard and

console.

2.

Remove drive belt

as

detailed

in

Lu-

brication Section. (See Fig. 1).

3.

Check condition of belt. Inspect for

cracks, fraying or

abnormal wear. (Un-

even wear, wear

on

one side, etc.). If ab-

normal wear

is

noted, probable cause

IS

pulley misalignment. (See your dealer).

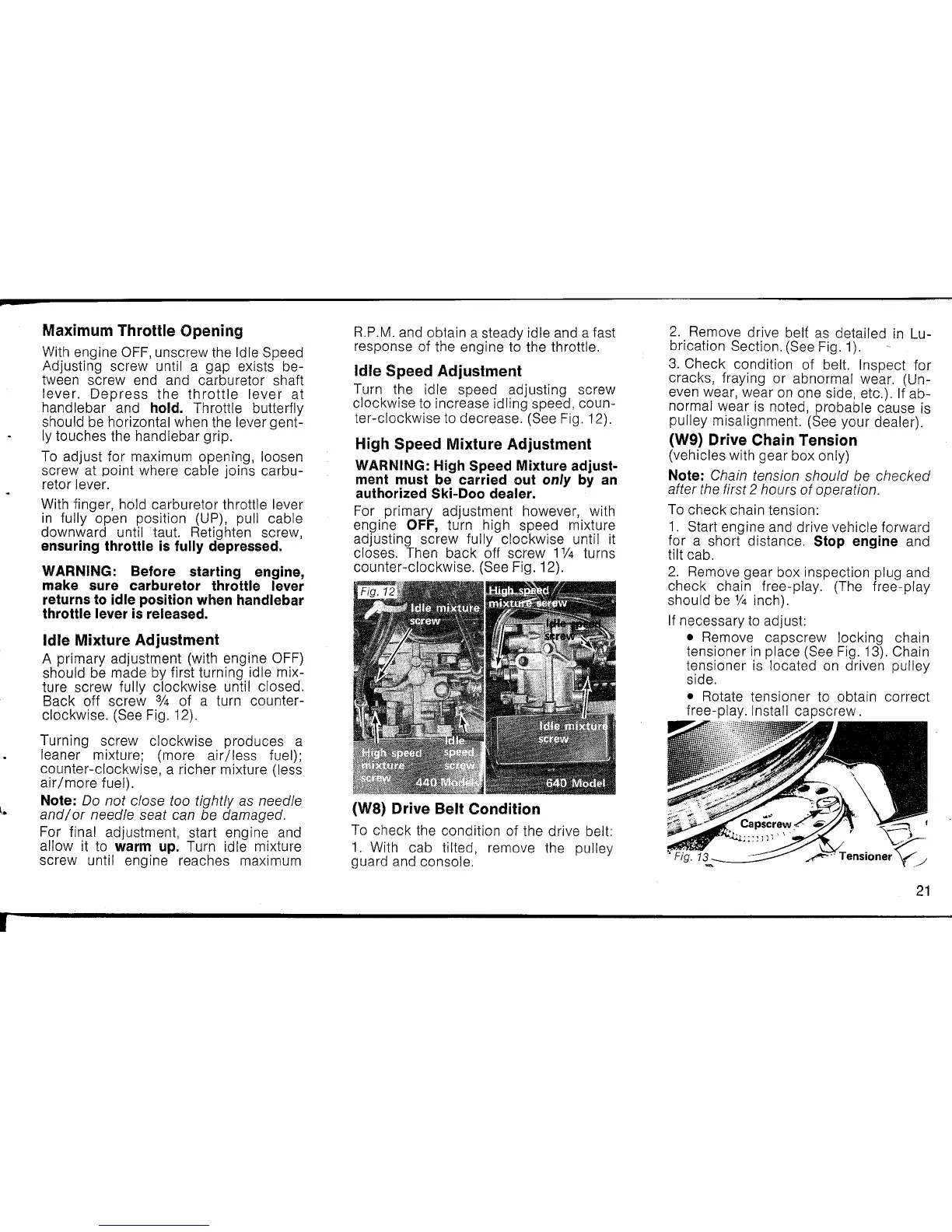

(W9) Drive Chain Tension

(vehicles with gear box only)

Note: Chain tension should be

checked

after the first 2 hours

of

operation.

To check chain tension:

1.

Start engine and drive vehicle forward

for a short distance.

Stop engine and

tilt cab.

2.

Remove gear box inspection plug and

check chain

free-play. (The free-play

should

be

V4

inch).

If necessary

to

adjust:

• Remove capscrew locking chain

tensioner

in

place (See Fig. 13). Chain

tensioner

is

located

on

driven pulley

side.

21

Loading...

Loading...