35

4. Properly position workpiece 5. Make sure workpiece is clamped 6 rmly against the table

and the fence.

5. Make sure all controls are locked before cutting.

WARNING

Use clamping position that does not interfere with operation. Before

switching on, lower head assembly to make sure clamp clears guard and

head assembly.

6. Activate the switch. Lower the head assembly and make your cut.

7. Wait until blade comes to a complete stop before returning head assembly to the raised

position and/or removing workpiece.

Please note: the inch-marking on the fence is for reference only. There is an off-set of the

zero-point while miter cutting.

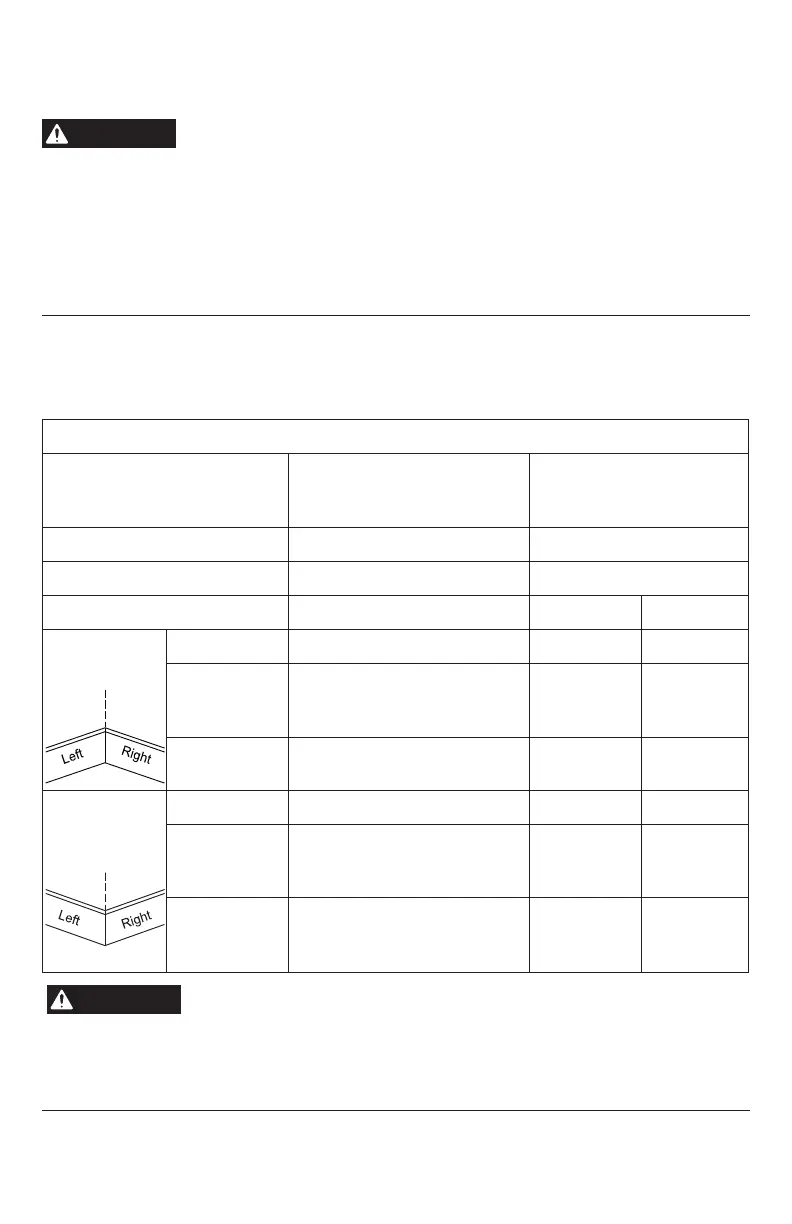

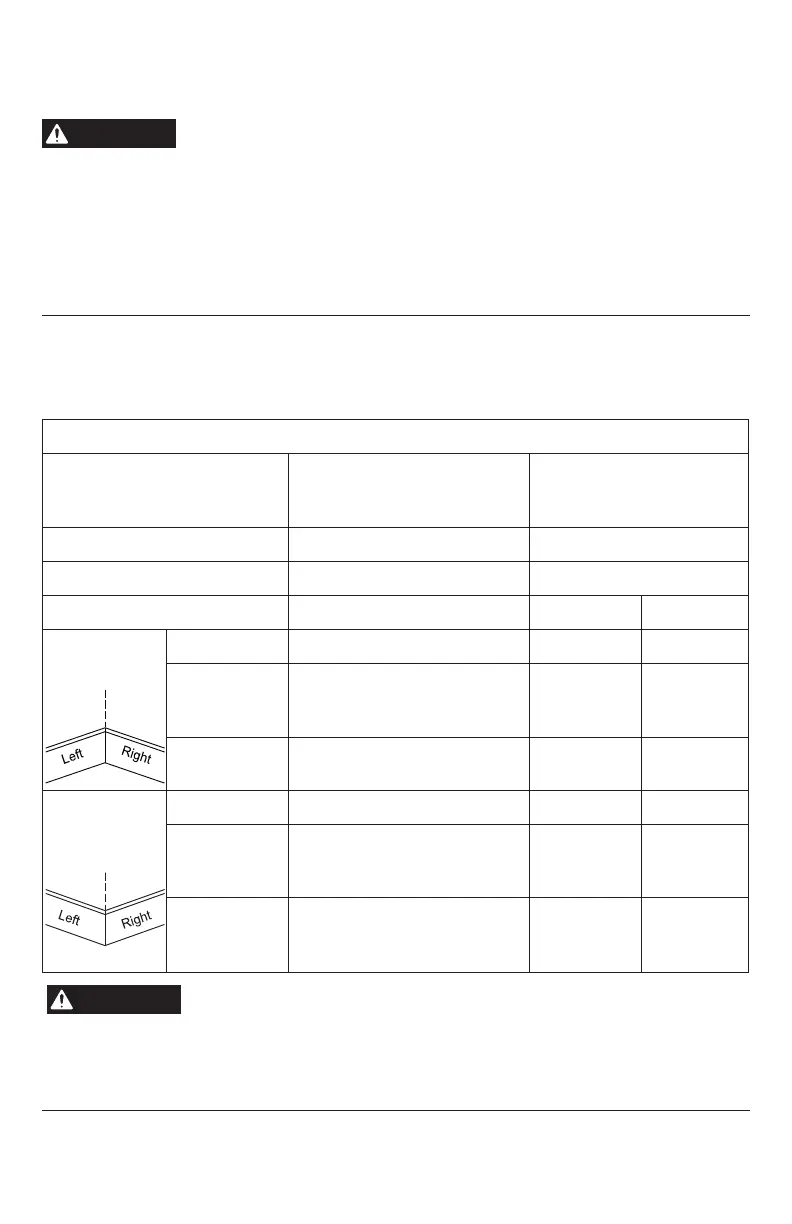

Base Molding

•

Base molding can be cut vertical against fence or at on the table.

•

Follow the table for helpful hints on cutting base molding.

BASE MOLDING CUTTING INSTRUCTIONS

SETTINGS

/

INSTRUCTIONS

Vertical Position Back of

molding is against the fence

Horizontal Position Back of

molding is at on the table

Sliding Fence Far Right Position Move to proper position

Bevel Angle 0° 45°

Molding position Left Side Right Side* Left Side Right Side*

Inside corner

of wall

Miter Angle Left at 45° Right at 45° 0° 0°

Molding

position

Bottom

against table

Bottom

against table

Top against

fence

Bottom

against

fence

Finished side Keep left side

of cut

Keep right

side of cut

Keep left

side of cut

Keep left

side of cut

Outside

corner of

wall

Miter Angle Right at 45° Left at 45° 0° 0°

Molding

position

Bottom

against table

Bottom

against table

Bottom

against

fence

Top against

fence

Finished side Keep left side

of cut

Keep right

side of cut

Keep right

side of cut

Keep right

side of cut

WARNING

Check for interference between workpiece and saw head components by

performing a dry cut. Interference can prevent proper saw operation and

cause injury and/or tool damage.

* If a piece of the saw head interferes with the workpiece while cutting it on the right side; it is

recommended to ip the workpiece and cut it to the left.

Loading...

Loading...