Before attempting any repair work, disconnect battery by turning main power disconnect switch to “ ” off

position. Preventive maintenance is the easiest and least expensive type of maintenance.

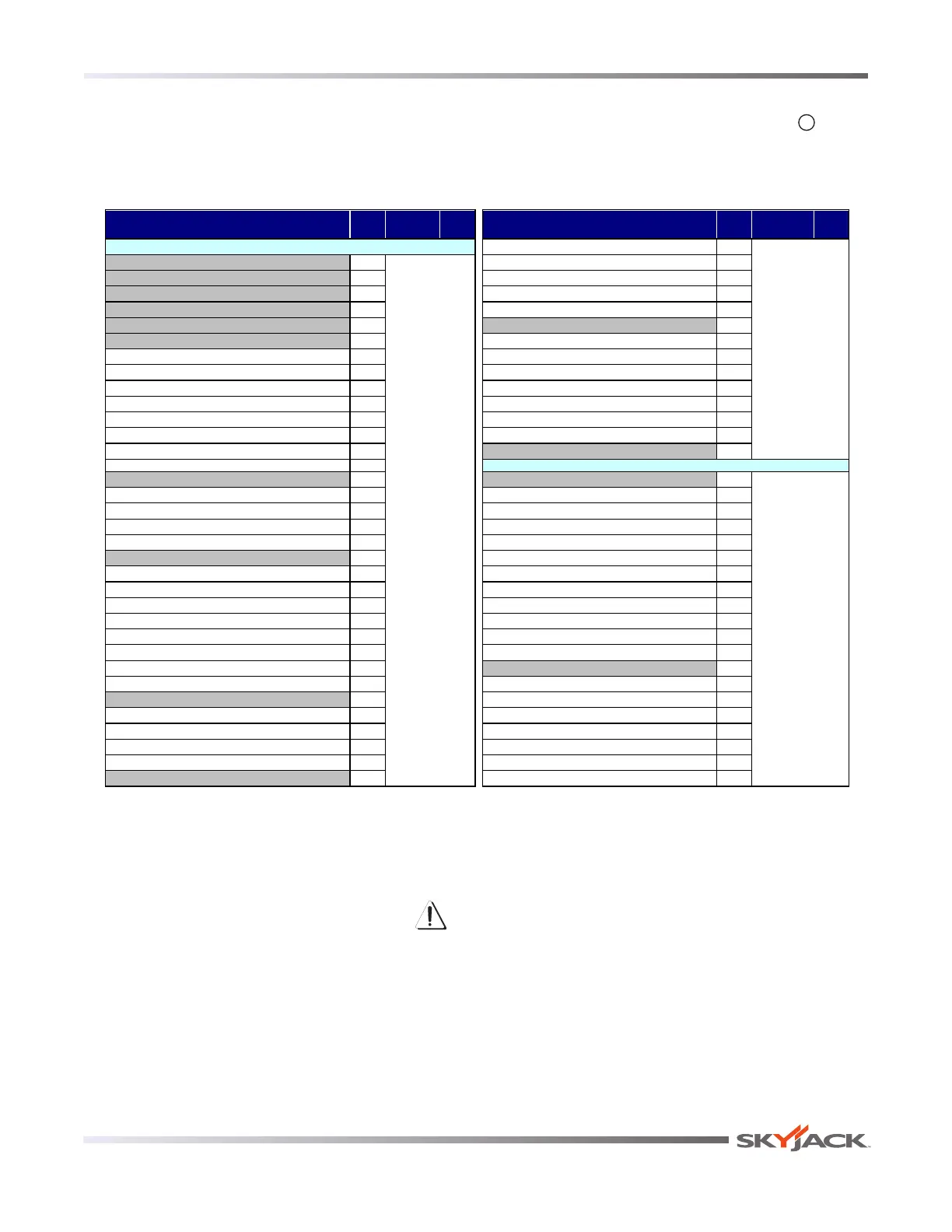

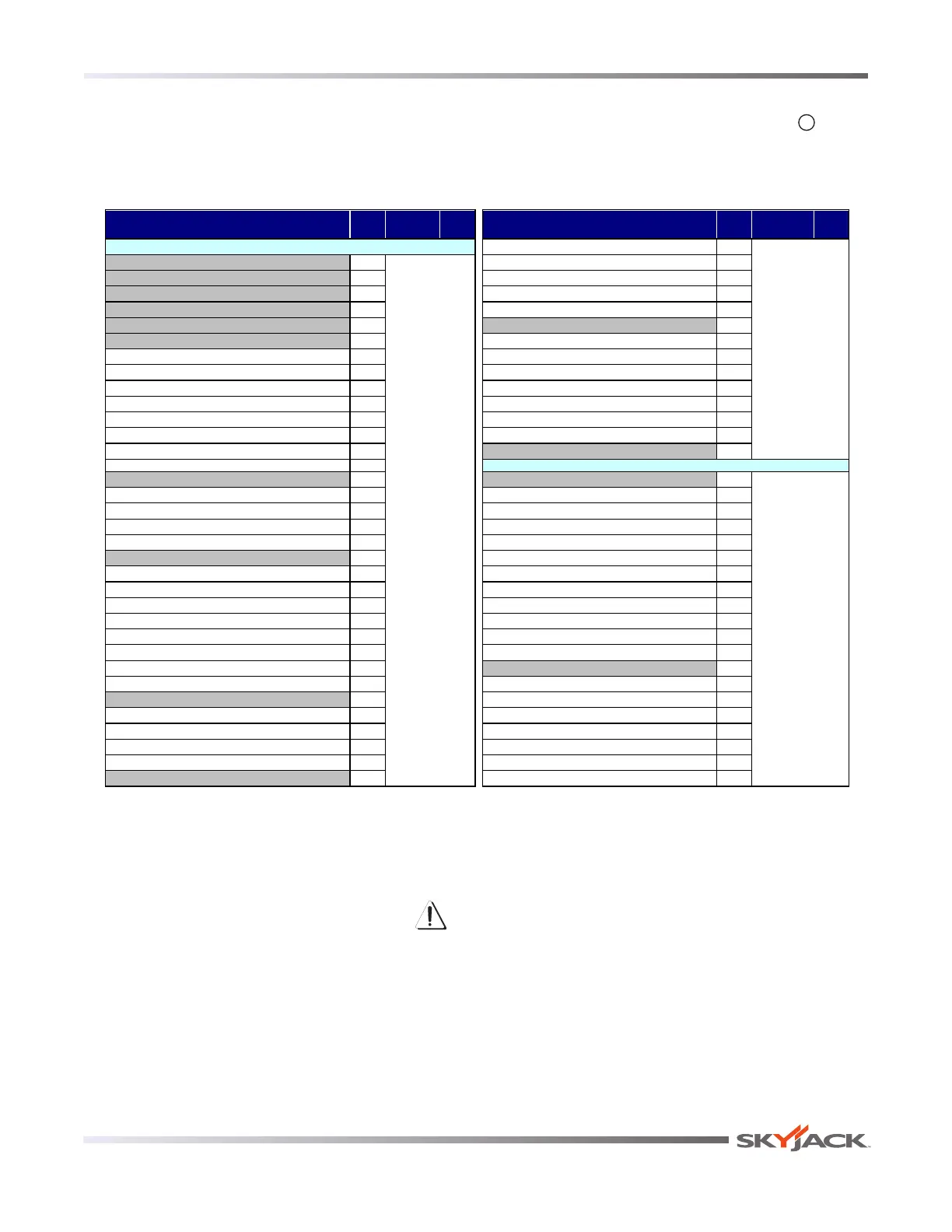

Frequency

Daily

3 months or

150 hours

Yearly

Frequency

Daily

3 months or

150 hours

Yearly

Sliders A

Labels A Maintenance Support A

Electrical A Scissor Assembly A

Limit Switches A Scissor Bumpers A

Hydraulic A Lift Cylinder(s) A

Emergency Lowering Access Rod (All models except 9250) A Base

Hydraulic/Electrical Compartment Base Weldment A

Main Power Disconnect Switch A Wheel/Tire Assembly A

Base Control Switches A Drive Axle A

Battery A Steer Cylinder Assembly A

Manifolds A Tie Rod A

Electrical Panel A Ladder A

Tilt Sensor A Outriggers (If Equipped) A

Hydraulic Tank (Model 9250) A Manuals A

Hydraulic Oil (Model 9250) A Function Tests

Hydraulic/Fuel Compartment Platform Control Console

Hydraulic Tank (Models 71xx & 8xxx) A Test Emergency Stop A

Hydraulic Oil (Models 71xx & 8xxx) A Test Lift Enable A

Fuel Tank A Test Platform Raising/Lowering A

Fuel Leaks A Test Enable Trigger Switch A

Engine Compartment Test Steering A

Engine Control Console A Test Horn A

Radiator A Test Driving A

Muffler and Exhaust A Test Brake A

Engine Tray A Test Speed Limit A

Hydraulic Pump A Test Powerdeck Enable (If Equipped) A

Engine Oil Level

A Test Extension Platform(s) (If Equipped) A

Engine Air Filter A Base Control Console

Fuel Leaks A

Test Emergency Stop

A

Platform Assembly

Test Base Lift Enable

A

Lanyard Attachment Anchors A

Test Lower/Neutral/Raise Switch

A

AC Outlet on Platform A Test Emergency Lowering (Models 71xx & 88xx) A

Platform Control Console A Test Emergency Lowering (Model 9250) A

Powered Extension Control Console (If Equipped) A Test Main Power Disconnect Switch

A

Lifting Mechanism Test Outriggers (If Equipped) A

60603AD-ANSI-R

Use original or manufacturer-approved parts and components for aerial platform.

Loading...

Loading...