Chapter 6 - Cleaning and maintenance

44

PERIODICAL CHECK OF SAFETY COMPONENTS

Some components are fundamental due to their contribution to safety and therefore they

require periodical checks. These components are listed hereafter with the relative control

frequency.

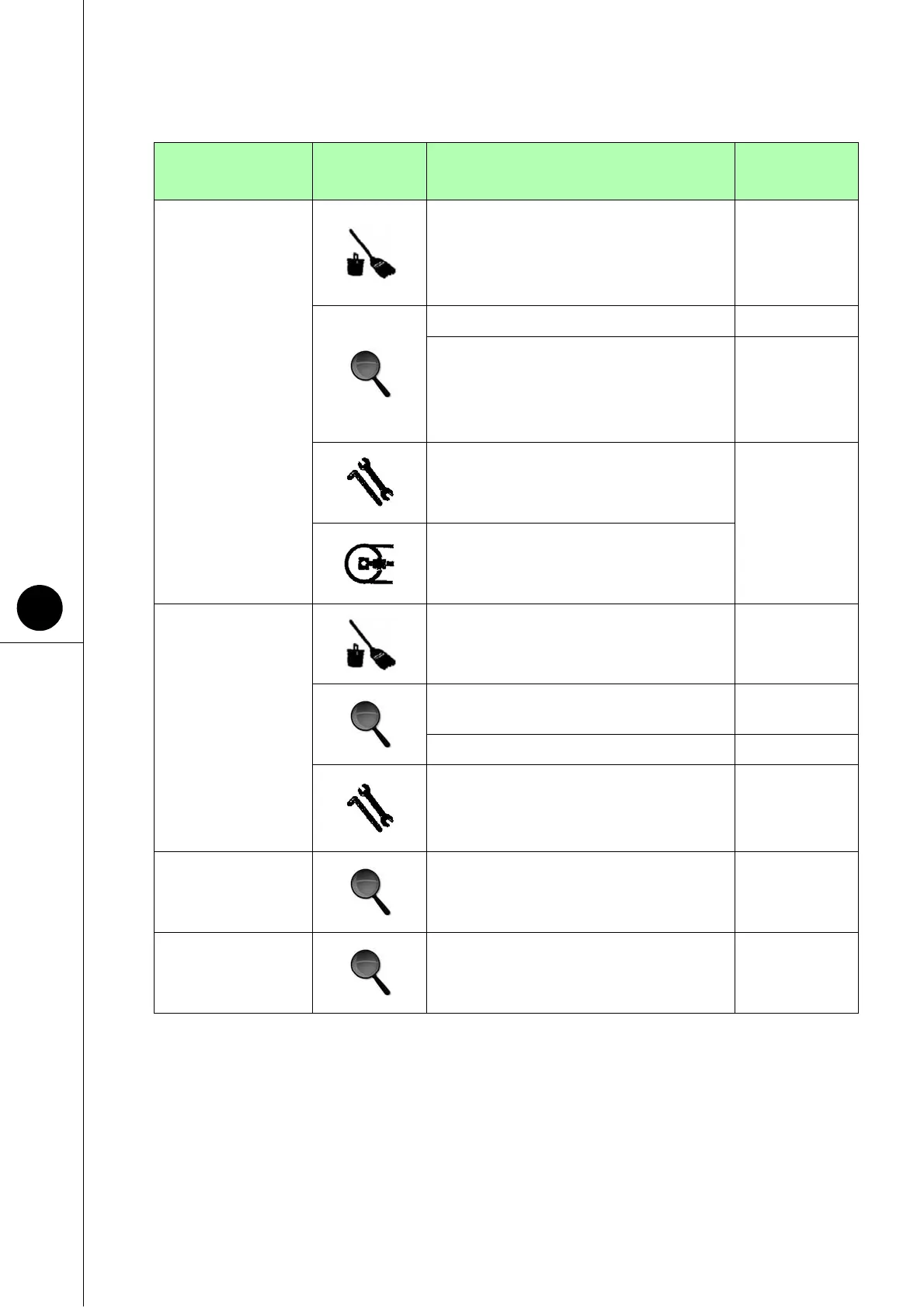

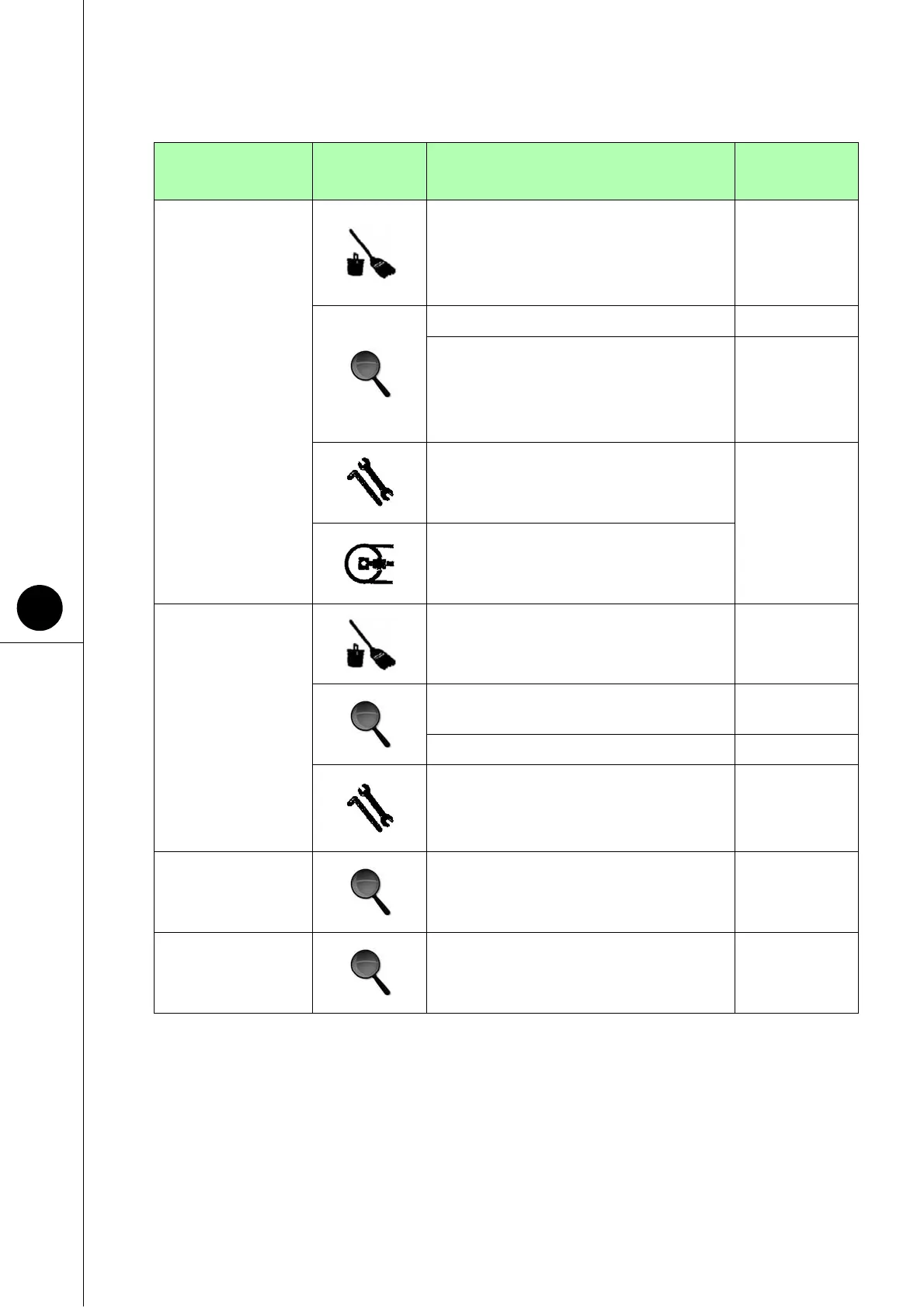

Tab. 6.1.1 - Interventions on mechanical components

Machine

device

Symbol

used

Operations

to be carried out

Frequency of

intervention

Sealing unit

Remove any film residue on the sealing

blade and top frame. Clean the sealing

blade with a moist cloth wearing

protective gloves to avoid cuts and/or

burns.

12 hours

Make sure the cutting blade is not worn. 60 hours

Check the state of wear of the PTFE

underneath the sealing bar and replace it

if necessary.

Check that the sealing rubber is intact.

240 hours

Make sure the cutting blade is not worn;

replace the blade if necessary.

1500 hours

Check the tensioning of the spring.

Conveyor belt

unit

Remove any film residue with

compressed air.

12 hours

Check that all the transmission

components work perfectly.

1500 hours

Check for unwanted noise. 1500 hours

Replace any parts that are damaged.

Check the transmission belt for signs of

wear.

1500 hours

Automatism unit

(Only FP560A -

FP870A)

Check the transmission belt for signs of

wear.

1500 hours

Cooling unit

Check the level of coolant and top up if

necessary.

60 hours

Loading...

Loading...