Use and maintenance manual FP560 - FP560A - FP870A

49

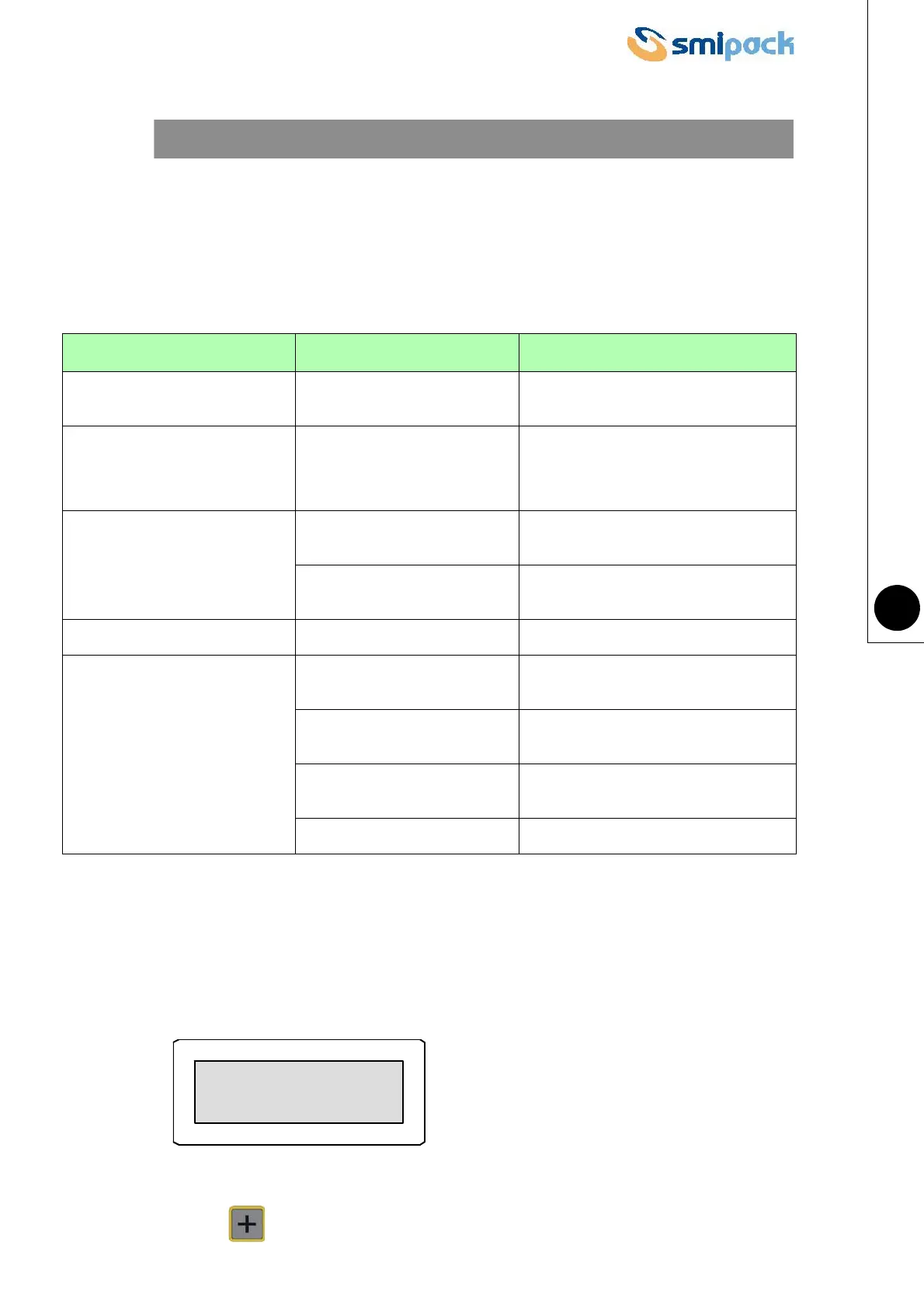

7.1 SOLUTIONS TO OPERATING PROBLEMS

The following table describes the solutions to the most common problems which can occur

while the machine is operating.

7.2 ERROR AND MESSAGE DISPLAYS

This paragraph describes the messages and errors that can be viewed on the display of the

operator panel with the relative solutions. These messages can be accompanied by an

acoustic signal.

After the cause has been removed, the error viewed on the display can be cancelled by

pressing

.

CHAPTER 7 - ANOMALIES AND FAULTS - HOW TO RESOLVE

PROBLEM CAUSE SOLUTION

PRESENCE OF SMOKE DURING

SEALING

The sealing temperature is set

too high.

Lower the sealing temperature.

BUBBLES REMAIN AFTER

HEAT SHRINKING ( Only use in

conjuction with shrinking

tunnel)

The film has no micro

perforations.

Pass the film through the machine micro

perforators.

SEALING OPENS DURING HEAT

SHRINKING ( Only use in

conjuction with shrinking

tunnel)

The sealing blade is dirty or

damaged.

Clean the sealing blade or replace it if

damaged.

The sealing value set in the

“parameters menu” is incorrect.

Adjust the sealing parameter more

accurately.

IRREGULAR SEALING

Low-quality film has been used. Replace the film.

THE FILM IS NOT SEALED

The sealing temperature is set

too low.

Increase the sealing temperature.

The sealing blade does not

receive properly.

Repair the power circuit of the sealing

blade.

The PTFE and/or silicon rubber

are worn.

Replace the PTFE and/or silicon rubber

The sealing blade is damaged. Replace sealing blade.

Loading...

Loading...