SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

1/2009

11

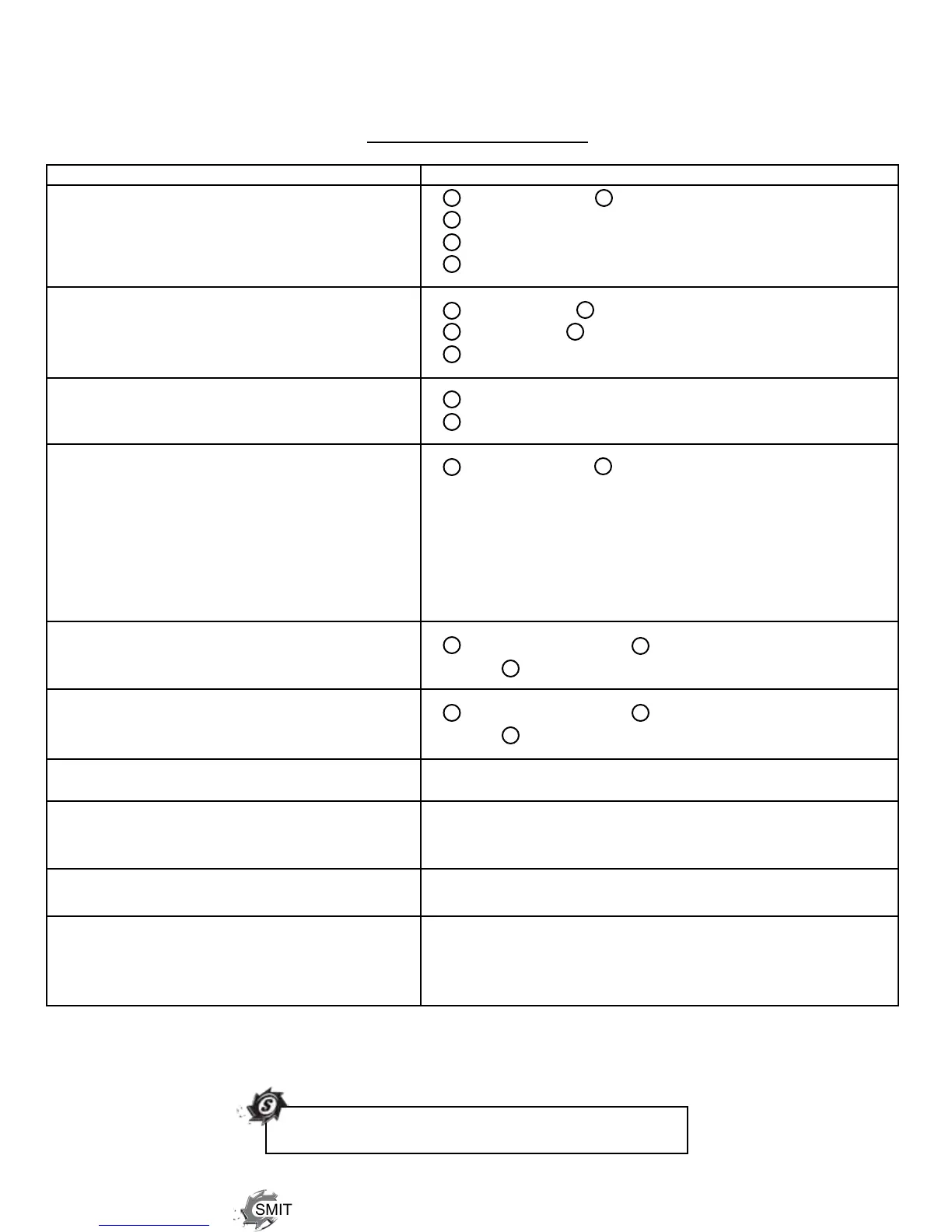

TROUBLESHOOTING

If engine does not start, read pg. 8

Problem Possible Reason(s)/Solution(s)

Cutters wearing unevenly/prematurely 1 Drum is too low, 2 Incorrect set-up,

3 Material build-up,

4 Cutters too tightly loaded, and/or

5 Wrong cutters for the job.

Cutter shaft breakage prematurely 1 Drum too low, 2 End plates or bushings worn,

3 Shafts worn, 4 Wrong cutter set-up and/or

5 Over 40 hours service-life.

Drum wearing prematurely or cracking 1 Drum hitting ground, and/or

2 Shafts and bushings not replaced within 40 hours.

Excess vibration 1 Bearing worn or 2 grease not getting into bearing.

- Line up grease hole

-Cleangreasetting

- Check Seals

- or Replace Bearing

Hex bushing worn, drive shaft worn, improper cutter

set-up, drum contacting ground, or wheels worn out.

Machine jumps erratically 1 Drum hitting ground, 2 RPM is too low,

and/or 3 Surface is severely uneven.

“V” belt wear prematurely 1 Pulley is misaligned, 2 Wrong belt,

and/or 3 Drum is contacting surface.

Cam lever will not raise/lower Raise or lower Hand-Wheel.

Hand-Wheel won’t turn Clean and grease threads, linkage may be bent, or

hand-wheel out of position.

Uneven Cutting Cutting too deeply, or rear wheel fork is bent.

AdjustableHandlebarisLoose InserttheatheadofascrewdriverbetweentheBolt

(Refer to pg. 5 diagrram) and Washer then tighten bolt with a 9/16” wrench

washer. Always keep tight!

For any other problems or questions, please contact your local representative

or SMITH Mfg today at 800-653-9311 or (954) 941-9744.

*Engine repair and engine warranty issues are handled

directly by your local engine service center.

SPS8

Loading...

Loading...