INSUFFICIENT PENETRATION

This error may be caused by the

following:

• High speed. Always make sure that the arc fully

pene

trates

the work piece and is never held at a forward angle of more

than 10 -15°. This will avoid incorrect

consump

tion of the

nozzle and burns to the nozzle

holder

.

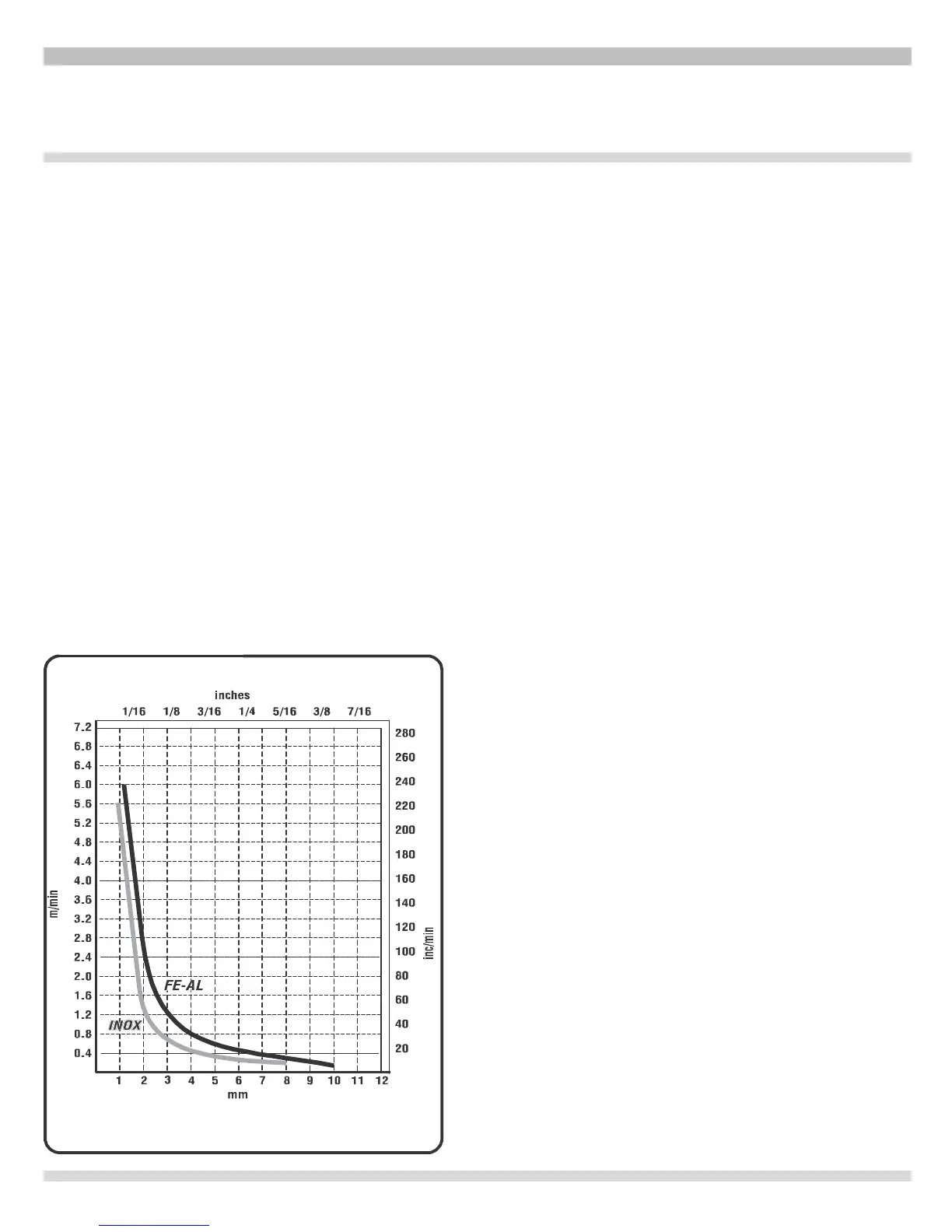

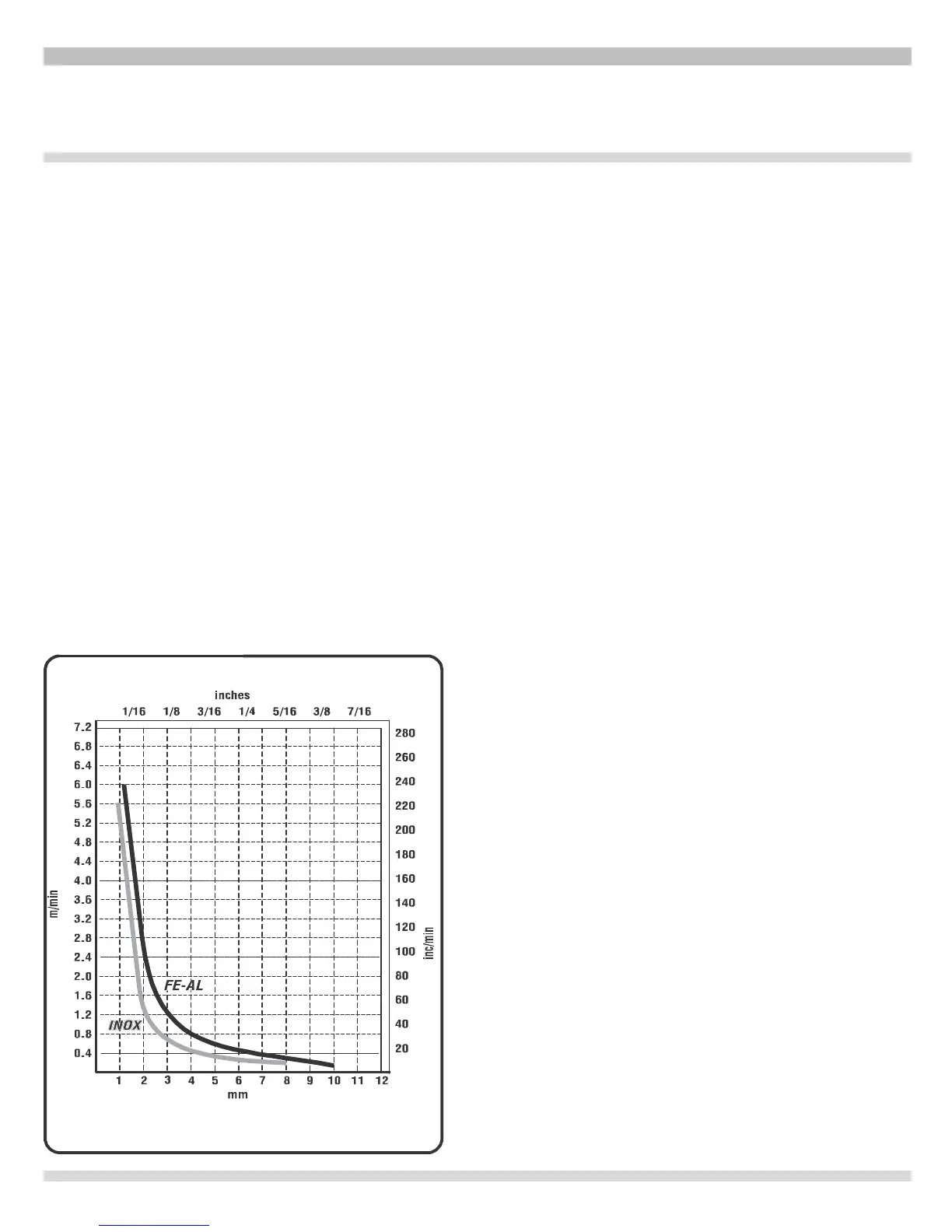

• Excessively thick work piece (see cutting speed

dia

grams, fig. 5).

• Grounding clamp not in good electrical contact with

the

work piece.

• Worn nozzle and electrode.

• Cutting current too low.

NOTE: When the arc does not penetrate, the

molten

metal scraps obstruct the nozzle.

THE CUTTING ARC GOES OFF

This error may be caused

by:

• Worn nozzle, electrode or swirl ring.

• Air pressure too high.

• Supply voltage too low.

REPLACING CONSUMABLE PARTS

Always shut off the machine before replacing

consu

mer parts.

• The electrode must be replaced when it has a crater in the

center approximately 1 mm deep (.039”) or slightly over

1/32”.

• The gas nozzle must be replaced when the hole is no

longer smooth and the cutting capacity is diminished.

• The swirl ring must be replaced when some areas are

blackened. Due to its small size, it is very important to

position it correctly during assembly (see fig. 4).

• The nozzle holder must be replaced when the insulating

part is deteriorated

Make sure that the electrode T, the swirl ring U and

the

gas nozzle V are mounted correctly, and that

the

nozzle holder W is firmly tightened.

If any of these parts are missing, this will interfer

e

with smooth operation of the machine and,

especial

ly,

jeopardize operator safety

SHORTER LIFE OF CONSUMABLE PARTS

This error may be caused by:

• Oil or dirt in the arc intake,

• Unnecessarily long pilot arc,

• Low arc pressure.

HELPFUL HINTS

• If the system air contains considerable amounts of moisture

and oil, it is best to use a drying filter to avoid excessive

oxidation and wear on consumable parts, damage to the

torch and a reduction in the speed and quality of the cutting.

• Make sure that the new electrode and nozzle to be mounted

are thoroughly clean and degreased.

• Always use original spare parts to avoid damaging the

torch.

Loading...

Loading...