17

EN

STEP 1

Installation

50.5

20

138

214

ATyS p 1250 AATyS p 800 to 1000 A

ATyS p 800 to 1600 A

ATyS p 2000 to 3200 A

ATyS p 1600 to 3200 A

33 8.58.5

50

3310

ø 9

ø 15

16 x 11

60

28.5 15.7515.75

28.515

15

5

5

12.5

25

25

30

30

45

45

90

ø12.5

Door cut-out for

front panel.

==

250

M

T

51,5

280

C 21

M

T

250

51.5

C21

Dimensions

in mm.

Caution:

Ensure that the

product is installed on

a flat rigid surface.

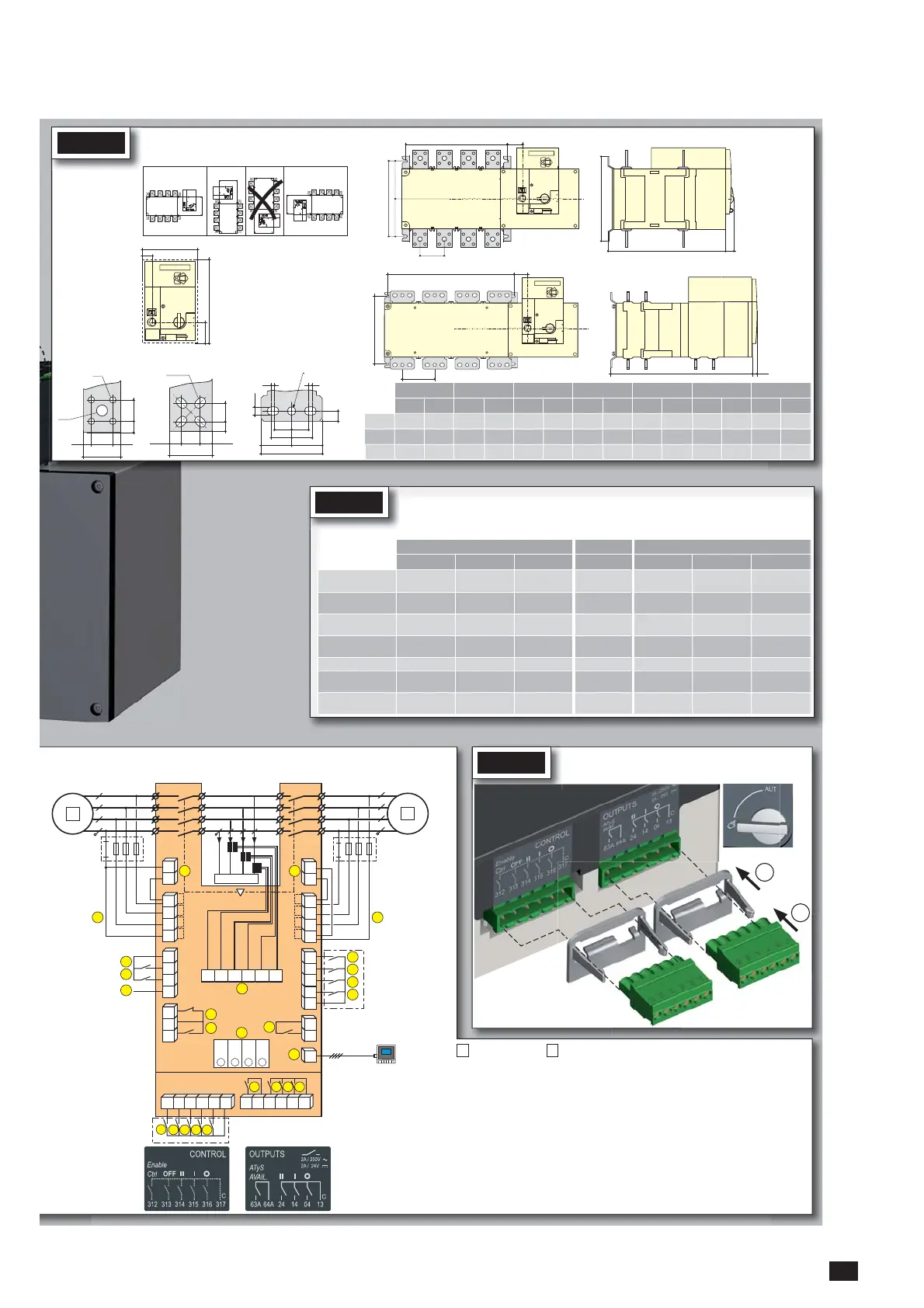

STEP 3

CONTROL / COMMAND Terminals

Ensure that the product is in Manual Mode.

5

6

4

3 2

1

2

7

104 103

312 313 314 315 316 317 63A 64A 24 14 04 13

8 9

10

RJ

102 101

105106

414 413415416417

64B 63B

72

201

71

202

205 206204203

210209208207

74

12

13

14

15

11

1

F1

F2

19

20

16

17

18

L1 L2 L3 N

L1 L2 L3 N

23

23

24

24

LOAD

21

22

R1 R2 S1 S2 T1 T2

Opt. 3

Opt. 2

Opt. 1

4

Opt. 4

3

2

1

Example: Control wiring for a 400VAC application having a 3 phase and neutral supply.

1

preferred source

2

alternate source

1. Position 0 order

2. Position 1 order

3. Position 2 order

4. Zero position priority order

5.

Remote Control Enable (Priority over Auto)

6. Product Available output (Motor)

7. Position II aux contact

8. Position I aux contact

9. Position 0 aux contact

10. O/P to ATyS D20 remote unit

11. Programmable Output Contact.

By default set to ATS Product

Available - Normally Open

12-15. Programmable Inputs 1-4

16-17. Programmable Inputs 5-6

18. Aux. Supply (207/210) to be used

with ATyS optional I/O modules

19. Contact “Start/Stop Genset” : if S1

is not available the NC contact le

contact (71-72) is close

20. Contact “Start/Stop Genset” : if S1

is not available the NO contact le

contact (71-74) is open

21. Option Module Slots 1 to 4

22. Current Transformer incoming cable

connections

23. Voltage Sensing Inputs

24. Power Supply Inputs

ATyS D20

Remote Control /

Display Unit

1

2

Recommended

orientation

Ok Ok

800 A 1000 A 1250 A 1600 A 2000 A 2500 A 3200 A

3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P 3 P 4 P

M 255 335 255 335 255 335 347 467 347 467 347 467 347 467

T 80 80 80 80 80 80 120 120 120 120 120 120 120 120

C 391 391 391 391 391 391 391 391 523 523 523 523 523 523

STEP 2

Power Terminal Connections

To be connected using terminal lugs, rigid or flexable busbars.

FRAME B6 FRAME B7 FRAME B8

800 A 1000 A 1250 A 1600 A 2000 A 2500 A 3200 A

Minimum cable section

Cu (mm

2

) at Ith

2x240 - - - - - -

Minimum cable section

Cu (mm

2

) at Ith

2x50x5 2x60x5 2x80x5 2x100x5

3x100x5 4x100x5 3x100x10

Maximum cable section

Cu (mm

2

)

2x300

4x185 4x185 6x185

---

Maximum Cu busbar

width (mm)

63 63 63 100

100 100 100

Type of screw

M8 M8 M10 M12 M12 M12 M12

Recommended tighten-

ing torque (N.m)

20 20 20 40 40 40 40

Maximum tightening

torque (N.m)

26 26 26 45 45 45 45

Loading...

Loading...