The steps in this chapter refer to module add-on power optimizers. For smart

modules, start from

Step 3: Connecting Power Optimizers in Strings

on page

21

Step 3: Connecting Power Optimizers in Strings

on page 21 Also refer to the

documentation supplied with the smart modules.

The power optimizer can be placed in any orientation.

If connecting more modules than optimizer inputs in parallel, use a branch

cable. Some commercial power optimizer models have a dual input.

Position the power optimizer close enough to its module so that their cables

can be connected.

Make sure to use power optimizers that have the required output conductor

length:

Do not

use extension cables between a module and a power optimizer,

between two modules connected to the same optimizer, or between two

optimizers other than in the cases specified below.

You can use extension cables between power optimizers only from row

to row, around obstacles within a row, and from the end of the string to

the inverter, as long as the maximum distance is not exceeded.

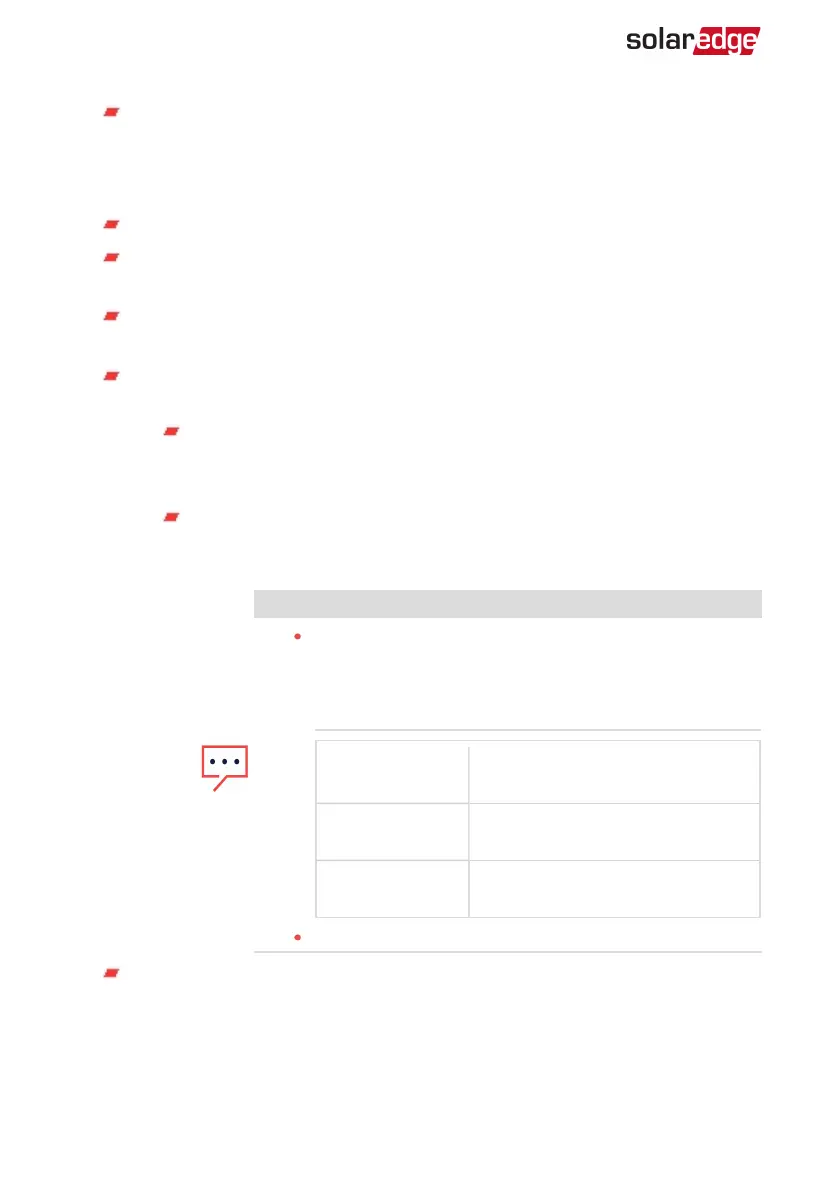

NOTE

The total conductor length of the string (excluding

power optimizers’ conductors; including home runs and

necessary extensions between optimizers) should not

exceed the following:

Inverter model

Total conductor length ( from DC+

to DC- of the inverter)

Three phase up to

SE25K

1000 ft. /300 m

Three phase SE25K

and above

2300 ft./ 700 m

Use at least 11 AWG/ 4 mm² DC cables.

Completely shaded modules may cause their power optimizers to temporarily

shut down. This will not affect the performance of the other power optimizers in

the string, as long as the minimum number of unshaded power optimizers

connected in a string of modules is met. If under typical conditions fewer than

-Three Phase System Installation Guide MAN-01-00057-4.1

18 Installation Guidelines

Loading...

Loading...