5.2 Check for transport damage

Check if the ZDNY series inverter has some visible external damage , such as cracks in

the housing or display please contact with your dealer if you find any damage.

The X1-LX series inverter is designed for outdoor installation (IP65)

Make sure the installation site does not fall into none of the following conditions:

Do not install the inverter in direct sunlight•

Do not install the inverter on flammable construction material•

Do not install the inverter in areas where highly flammable materials are stored.•

Do not install the inverter in potentially explosive areas.•

Do not install the inverter in the cool air directly.•

Do not install the inverter near the television antenna or antenna cable.•

Do not install the inverter in higher than the altitude of about 2,000 m above •

sea level.

Do not install the inverter during periods of precipitation or high humidity (>95%);•

Moisture trapped within the location may cause corrosion and damage to the

electric components.

Install the inverter in a location that maintains an ambient air temperature •

which is less than 45°C;That is to maintain a safe internal component

temperature, the inverter reduce power if the ambient air temperature

exceeds 45°C

The inverter should be installed in a location that is not accessible for children.•

The inverter emits a slight vibrating noise when operating, This noise is normal•

and no effect on performance.

The slope of the wall should be within ±5°.•

Keep the inverter far away from the seawater.•

The inverter is heavy, ensure the mounting place is strong enough to hold the•

weight of the inverter.

If you install the inverter in a cabinet, closet or other small enclosed area, •

sufficient air circulation must be provided in order to dissipate the heat

generate by the unit.

5.3 Installation precaution

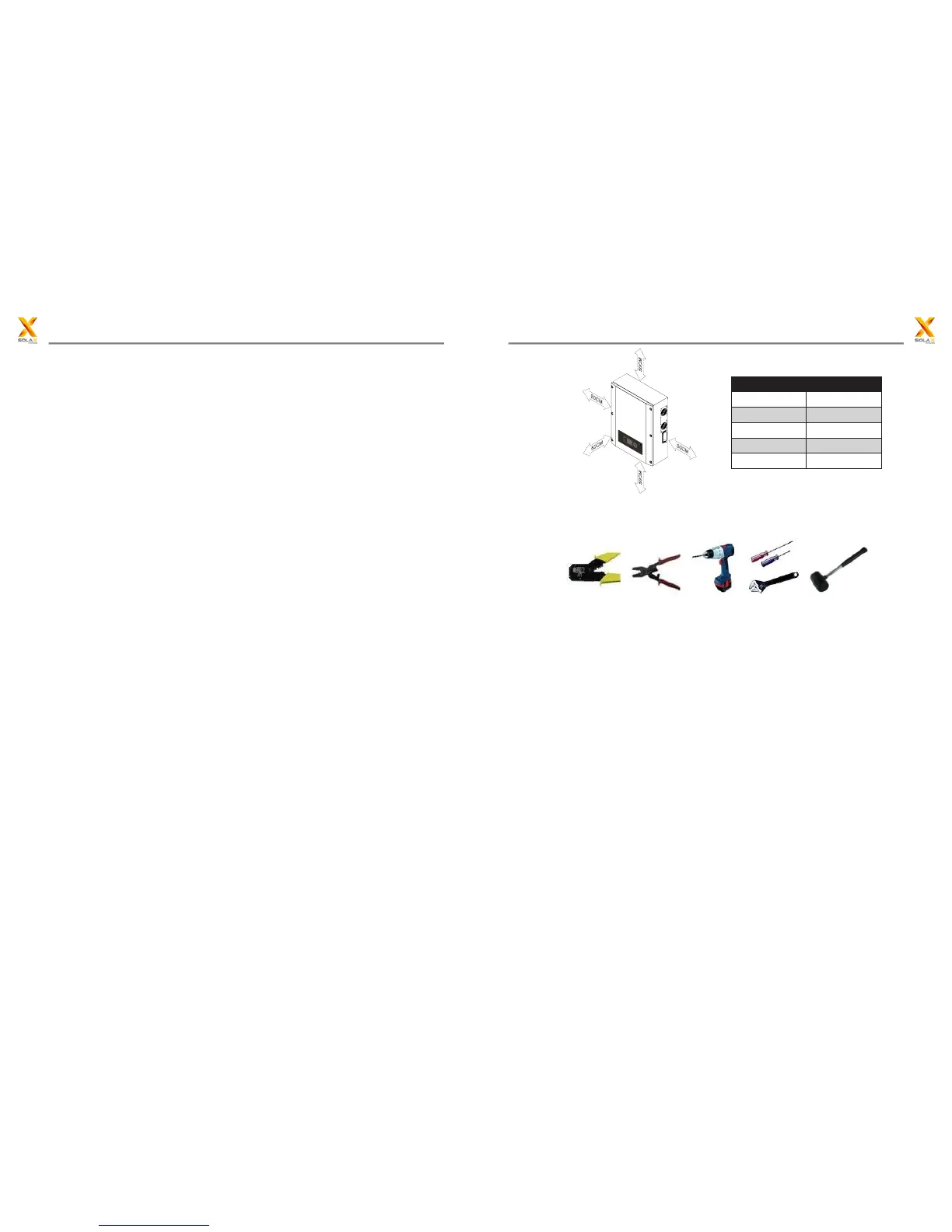

Available space size

Position

Side

Top

Bottom

Front

Min.Size

50cm

50cm

50cm

50cm

5.4 Preparation

Below tools are needed before installation.

Installation Tools

Installation Tools: crimping pliers for binding post and RJ45, screwdriver, manual wrench,

ф 8 driller and rubber hammer.

Lifting and Handling

The unit is heavy. Do not lift it alone.

• During lifting procedures ensure that the unit is firmly secured to avoid the risk

of accidental tipping or dropping.

• Parts serving for support or immobilization of unit shall be designed and

manufactured so as to minimize the risk of physical injuries and of accidental

loosening of fixing.

• Ensure that the method of lifting will not allow the unit to slip from chains and

slings or turn-over or slide from lifting devices.

• Transportation must be carried by specialized person (truck operators. hook-up

personal), equipped with the necessary protection equipments (overalls, safety

shoes, protective gloves, helmets, goggles)

• Do not walk or stand beneath or in the proximity of the load.

• Avoid sudden movements and jolts when unloading and positioning the unit.

Internal handling procedures must be conducted with care. Do not exert

leverage on the components of the machine.

• If the unit is not balanced apply ballast. Any protruding parts should not be

supported by hand.

• The inverter should be installed so that the operating panel shall be easily

accessible- easy access to the electrical power connection point.

• Accessible for maintenance and repair work.

17

16

5 Installation5 Installation

Loading...

Loading...