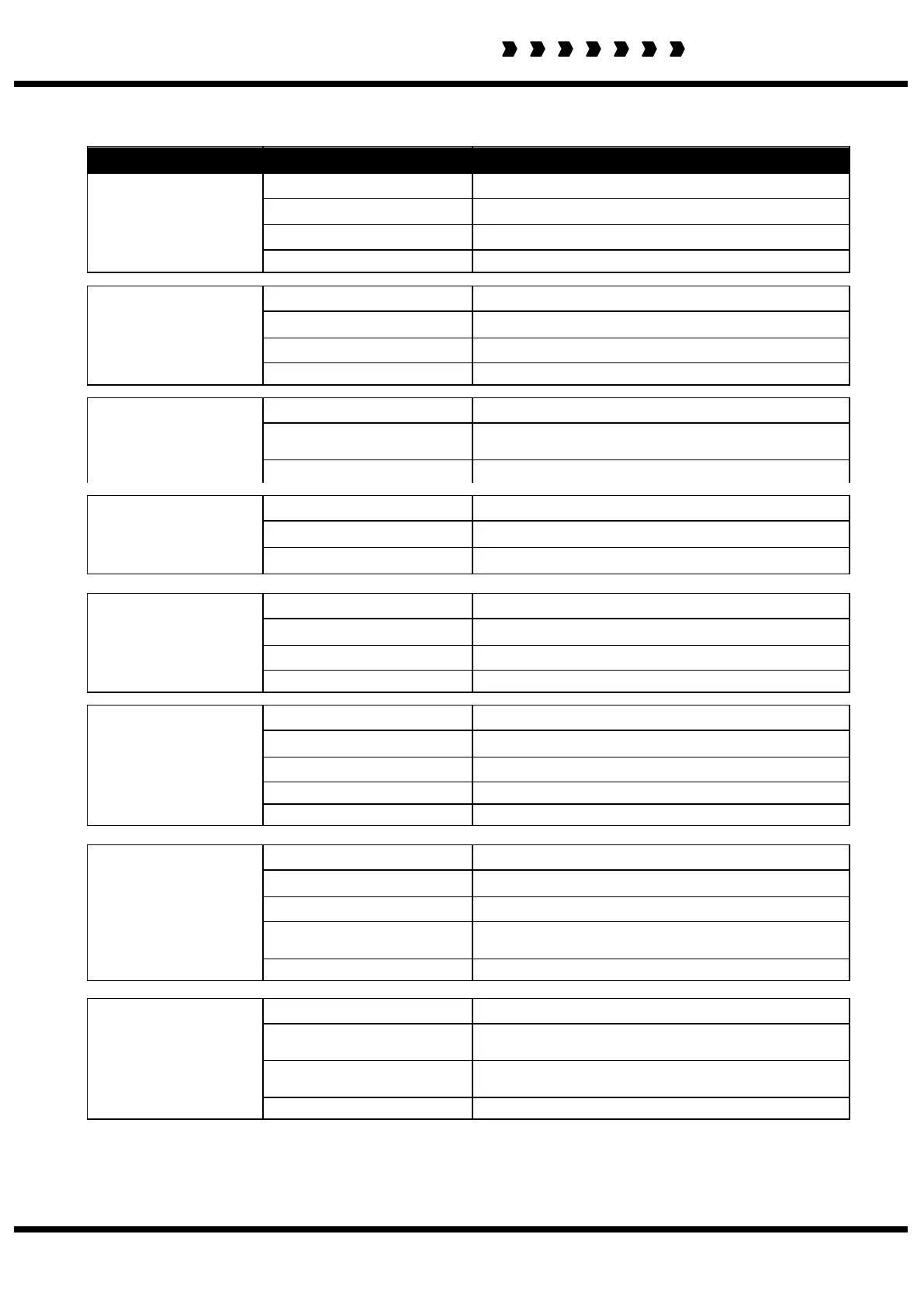

Oil level incorrect Check oil level

Ensure tractor PTO speed matches implement

Belt and pulley condition Replace if necessary

Reduce forward speed or increase height of cut

Working angle to great Reduce offset of implements

Shaft incorrect length I.e.

bottoming out

Resize PTO shaft as recommended

Grease PTO shaft as recommended

Flails worn Replace worn flails

Look for suitable conditions

Rotor out of balance See rotor vibration

Grease bearings to schedule

Flails broken or missing Replace flails

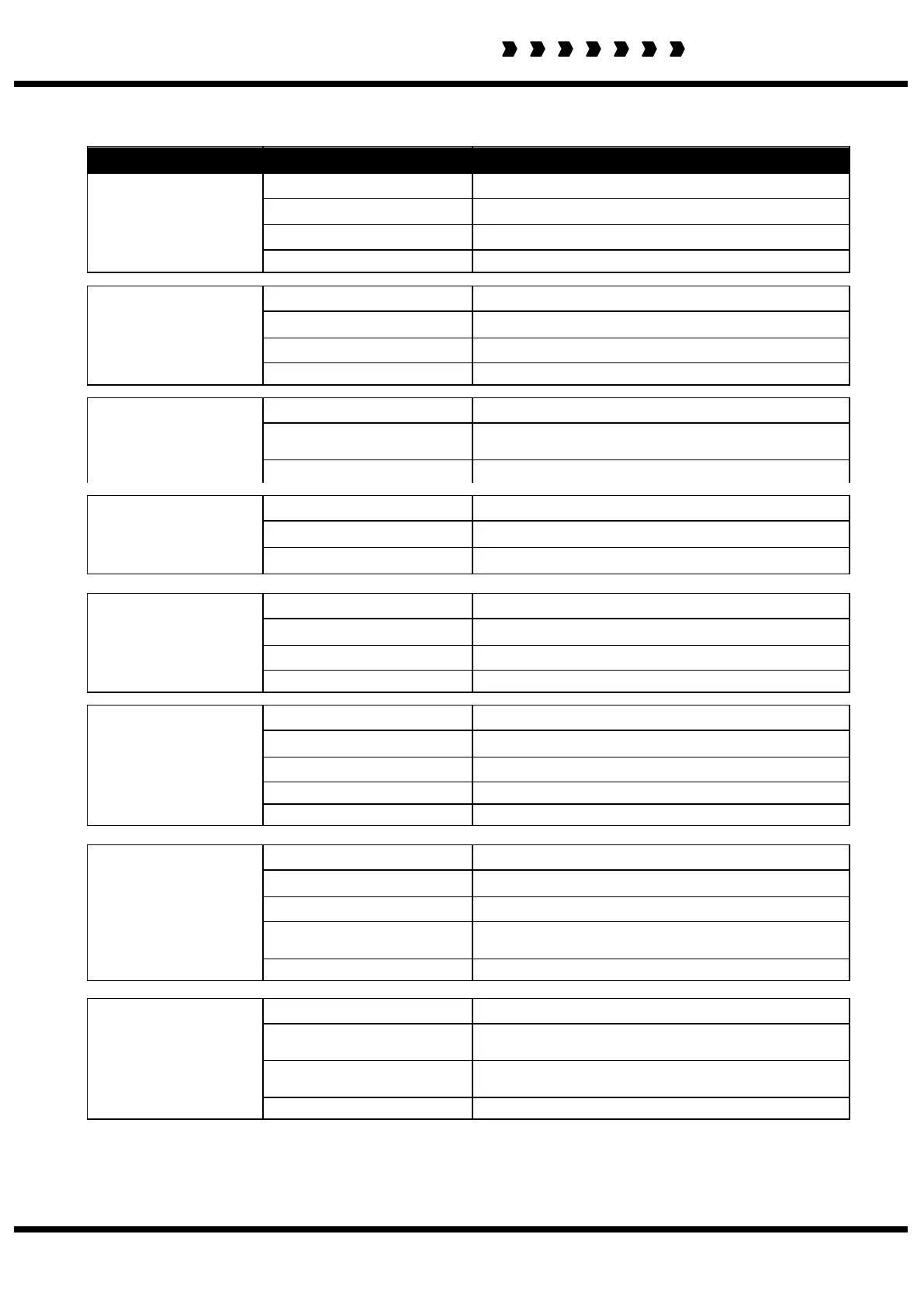

Oil level incorrect Fill tank to correct level

Drain and refill tank with correct grade oil

Ensure the tractor's PTO speed matches implement

Ambient temperature too

high

Reduce work rate / install oil cooler

Reduce forward speed or increase height of cut

Machine overloaded Reduce forward speed or increase height of cut

Break-back operating

Frequently

Machine being used on

excessive incline

Weight of machine being

carried upon rear roller

Use Autopilot or head float

Excel 606, 686, 726 & 836

Loading...

Loading...