IM-P146-01 CMGT Issue 4

10

4. Commissioning

5. Operation

6. Maintenance

Note: Before actioning any maintenance programme observe the 'Safety information' in Section 1.

Warning

The inner and outer gaskets used when installing/maintaining the UFT32 to a PC_ pipeline connector

contain thin stainless steel support rings which may cause physical injury if not handled and

disposed of carefully.

6.1 General information

Before undertaking any maintenance on the trap it must be isolated from both the supply line and return line

and any pressure allowed to safely normalise to atmosphere. The trap should then be allowed to cool. When

reassembling, ensure that all joint faces are clean.

6.2 Replacement of the trap unit:

-

Ensure that the correct tools and necessary protective equipment are used at all times.

-

Replacement of the trap unit is achieved by removing the two connector screws (3) and removing the trap.

-

Always use new connector screws, as supplied with the new trap, when replacing a universal trap.

-

The new trap unit should be positioned against the connector gasket face and apply a small amount of

anti-seize compound to the threads of the connector screws.

-

Tighten screws finger tight and ensure that the trap body is parallel to the connector.

-

Tighten the screws to the recommended torque (see Table 1).

-

Open isolation valves slowly until normal operating conditions are achieved.

-

Check for leaks.

After installation or maintenance ensure that the system is fully functioning. Carry out tests on any alarms

or protective devices.

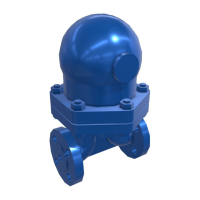

The float trap is a continuous discharge trap, removing condensate the instant it forms. On start-up, the

thermostatic air vent allows air to bypass the main valve preventing the system air binding. Hot condensate

will close the air vent tightly, but as soon as it enters the main chamber of the trap, the float rises and the

lever mechnism attached to it opens the main valve - keeping the system drained of condensate at all times.

When steam arrives, the float drops and closes the main valve. Float traps are renown for their high start-up

load handling capability, clean tight shut-off and resistance to waterhammer and vibration.

Loading...

Loading...